NOTE: The assembly does not have a dot on the certification mark when it is crimped with Tyco

68006, 68007 and 68008 die sets. The dot on the symmetrical pap is not necessary for a

size 4AL 13-78 terminal lug.

NOTE: It is normal to have:

• Flash or flaked plating where the nest and indenter dies go together during the crimp

operation

• Exposed base material in the indenter area that is caused by the crimp operation.

Refer to Figure 21.

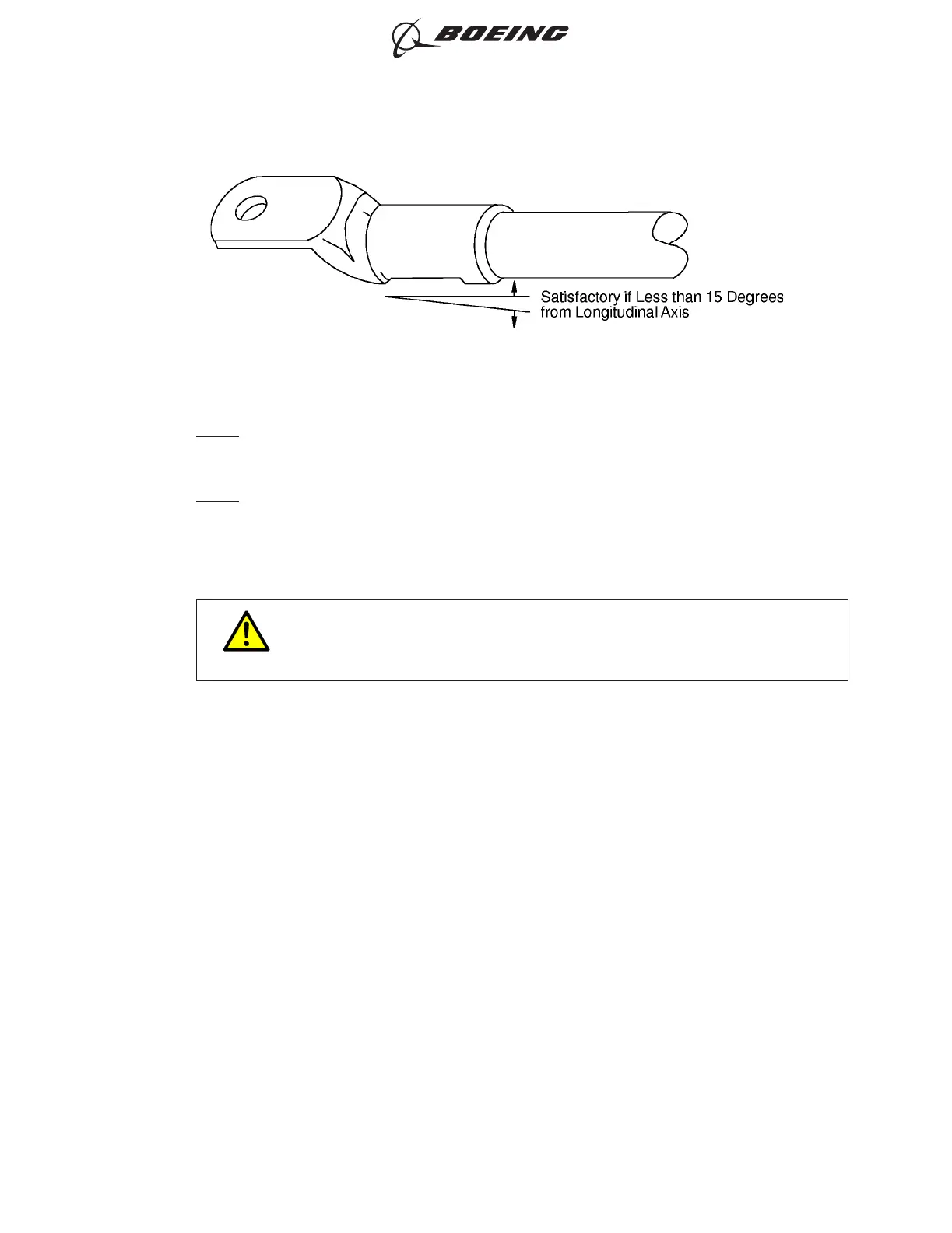

CAUTION

IF THE TONGUE OF A BACT13T TERMINAL LUG HAS A BEND THAT IS

MORE THAN 0.15 INCH FROM THE LONGITUDINAL AXIS OF THE

BOTTOM SURFACE OF THE TONGUE, THE TERMINAL LUG IS DAMAGED

AND MUST NOT BE USED.

(11) If the crimp area has flash that is caused by the crimp operation:

(a) Make a selection of a file from Table 22.

(b) Remove the flash with file.

Make sure that the width of the filed area is not more than 0.124 inch.

(c) Remove the filings from the assembly.

(12) If the crimp area has flaked plating that is caused by the crimp operation, remove the flaked

plating.

(13) Install the insulation sleeve. Refer to Paragraph 2.N..

STRAIGHTNESS OF THE TERMINAL LUG ASSEMBLY

Figure 22

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 32

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...