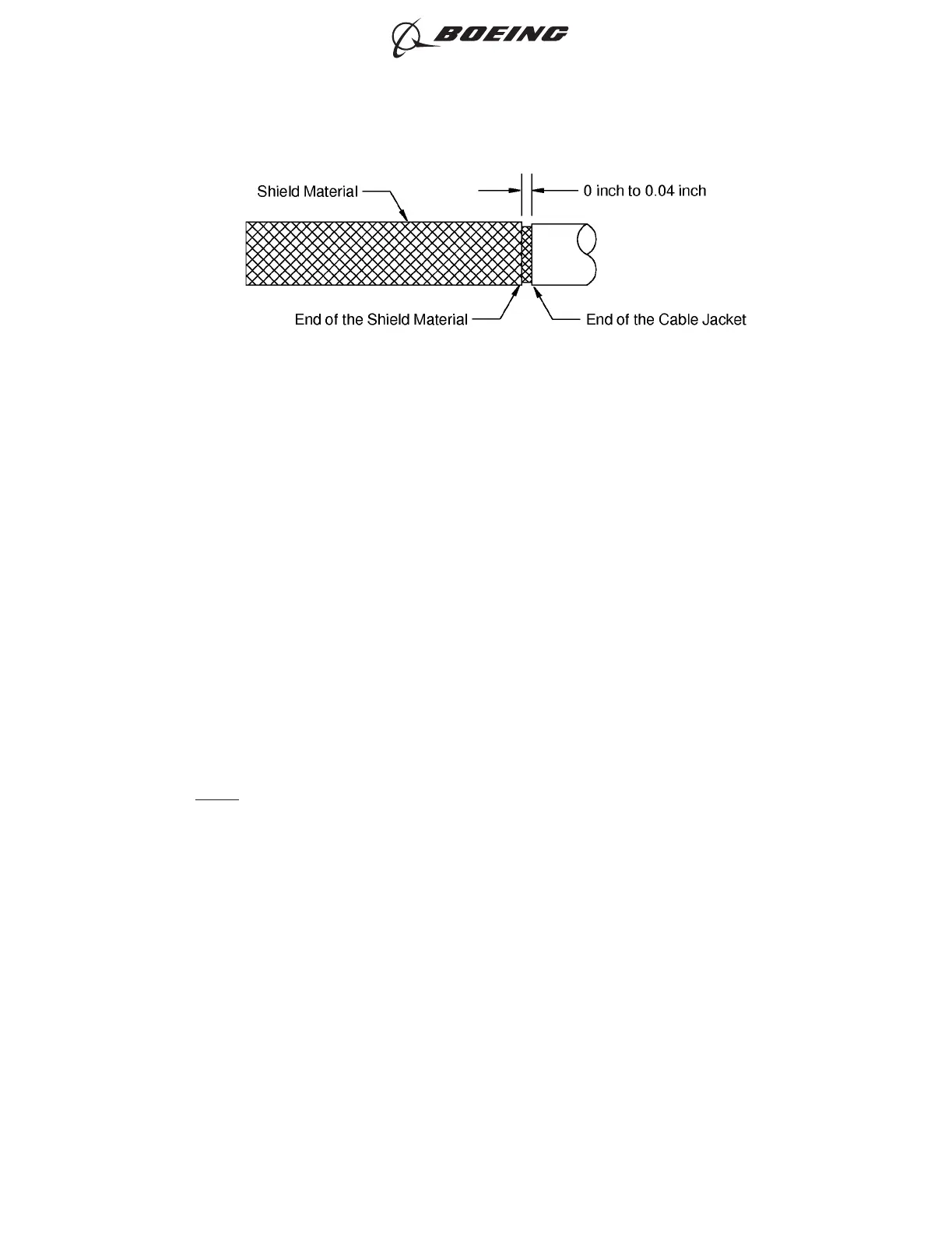

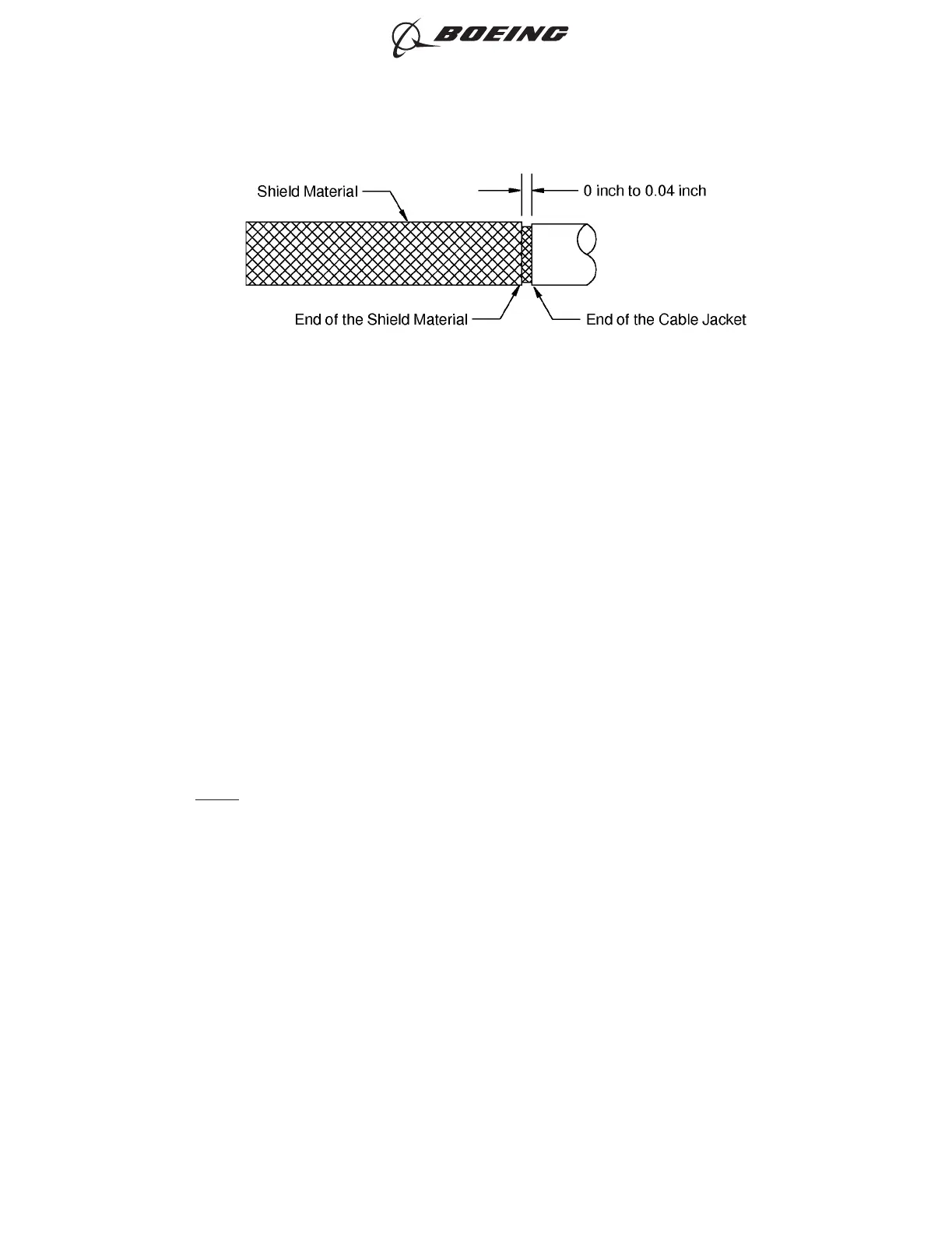

(6) If the shield material makes an overlap with the cable jacket, remove the unwanted length with

scissors or an equivalent tool.

(7) Twist the end of the shield material until it is tight against the shield of the cable.

(8) For a cable where the shield is not folded back, install the other solder sleeve at the end of the

shield material.

Refer to:

• Figure 6

• Subject 20-10-15 for the procedure to install the solder sleeve

Make sure that:

• The rear edge of the solder ring is approximately 0.1 inch from the end of the cable jacket

• The rear seal ring does not make an overlap with the shield

• The heat is applied at the end of the solder sleeve that is on the shield material first

• The heat applied at the other end of the solder sleeve to melt it around the cable jacket

• The heat applied at the center of the solder sleeve and the cable is turned in the reflector

until the solder melts.

NOTE: A change of the color of the sleeve is permitted if the solder joint can be seen.

POSITION OF THE SHIELD MATERIAL AT THE END OF THE CABLE JACKET

Figure 5

ASSEMBLY OF BACS52P SERIES AND D-150-0300 SERIES SHIELDED SPLICE ASSEMBLIES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-20

Page 73

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...