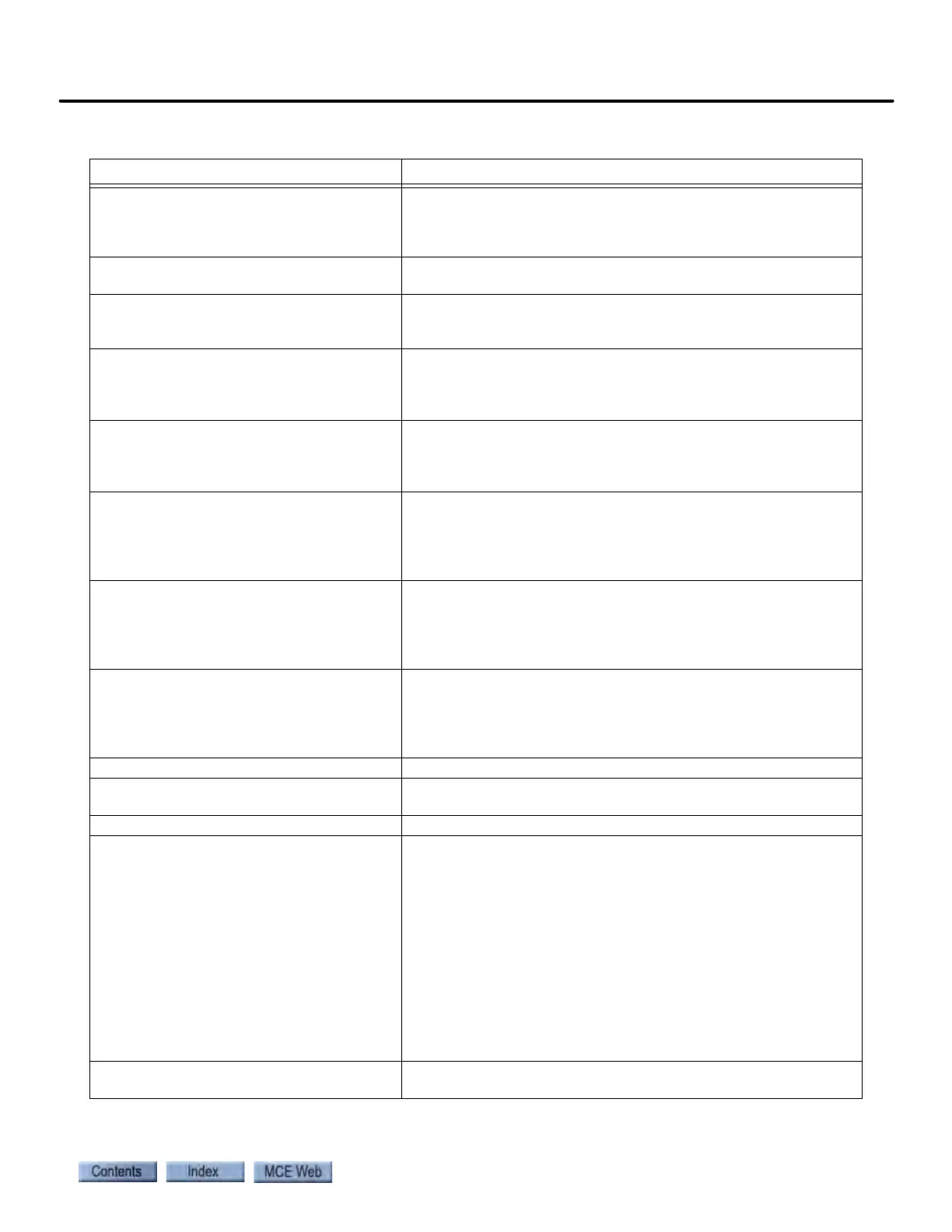

Software Testpoint Signals

11-5

11

iControl DC

Load Weigher Balanced This signal is used to determine the amount of pretorque that

the controller needs to provide to the motor to help prevent roll-

back on takeoff. 0 = balanced load. Please refer to “Pretorque

Gain Adjustments” on page 4-22.

Load Weigher Feedback This signal represents the smoothed, processed Load Weigher

(Signal), captured with doors closed, just before departure.

Motor Contactor Status Indicates status (open/closed) of motor contactor. When the sig-

nal is high, the contacts are closed. When the contactor is closed

AND the motor field module is enabled, the motor will run.

Over Current Armature current signal used for Loop Over Current. Adjusted

using Rated Loop Over Current and Loop Over Current Fault

Time. Please refer to “Armature Overcurrent Overload Protection

Adjustment (System 12 SCR Drive)” on page 4-48.

Over Current Power Armature power accumulated. Used for Loop Over Current.

Adjusted using Rated Loop Over Current and Loop Over Current

Fault Time. Please refer to “Armature Overcurrent Overload Pro-

tection Adjustment (System 12 SCR Drive)” on page 4-48.

Over Current Power Threshold The armature power threshold above which a Loop Over Current

fault is generated. Adjusted using Rated Loop Over Current and

Loop Over Current Fault Time. Please refer to “Armature Over-

current Overload Protection Adjustment (System 12 SCR Drive)”

on page 4-48.

Over Current Threshold Armature current signal threshold above which over current

power is accumulated. Used for Loop Over Current. Adjusted

using Rated Loop Over Current and Loop Over Current Fault

Time. Please refer to “Armature Overcurrent Overload Protection

Adjustment (System 12 SCR Drive)” on page 4-48.

Pattern (Command) Post-filtered pattern command signal. Please refer to “Verify Pat-

tern Command and Drive Speed Feedback” on page 2-67. Please

refer to “Verifying a One Floor Run” on page 4-5. Please refer to

“Pattern Scaling (System 12 SCR Drive)” on page 4-9. Please

refer to “Setting Pattern Parameters” on page 4-19.

Pattern (Directional) Directional pattern signal.

Pattern (Filtered) Pre-filtered pattern signal. Please refer to “Tach Error Tripping

Threshold Adjustment” on page 2-68

Pattern (Interpolated) Interpolated (smoothed) pattern signal.

Pattern (Phase) The numbers displayed represent segments of the speed profile.

Please refer to “Shaping the Speed Profile” on page 4-17.

0 = Idle

1 = Initial Jerk

2 = Acceleration

3 = Low Roll Jerk (during acceleration, high speed is reached)

4 = Peak (High Speed)

5 = High Roll Jerk (during acceleration, high speed not reached)

6 = High/Low Roll Jerk (during deceleration)

7 = Deceleration

8 = Flare Jerk (transition from deceleration to leveling)

9 = Approach Jerk (transition from deceleration to leveling)

10 = Leveling

Pattern (Raw) Raw pattern signal. Please refer to “Speed Loop Gains (System

12 SCR Drive)” on page 2-66

Table 11.2 Test Point Signals

Test Signal Description / Text References

Loading...

Loading...