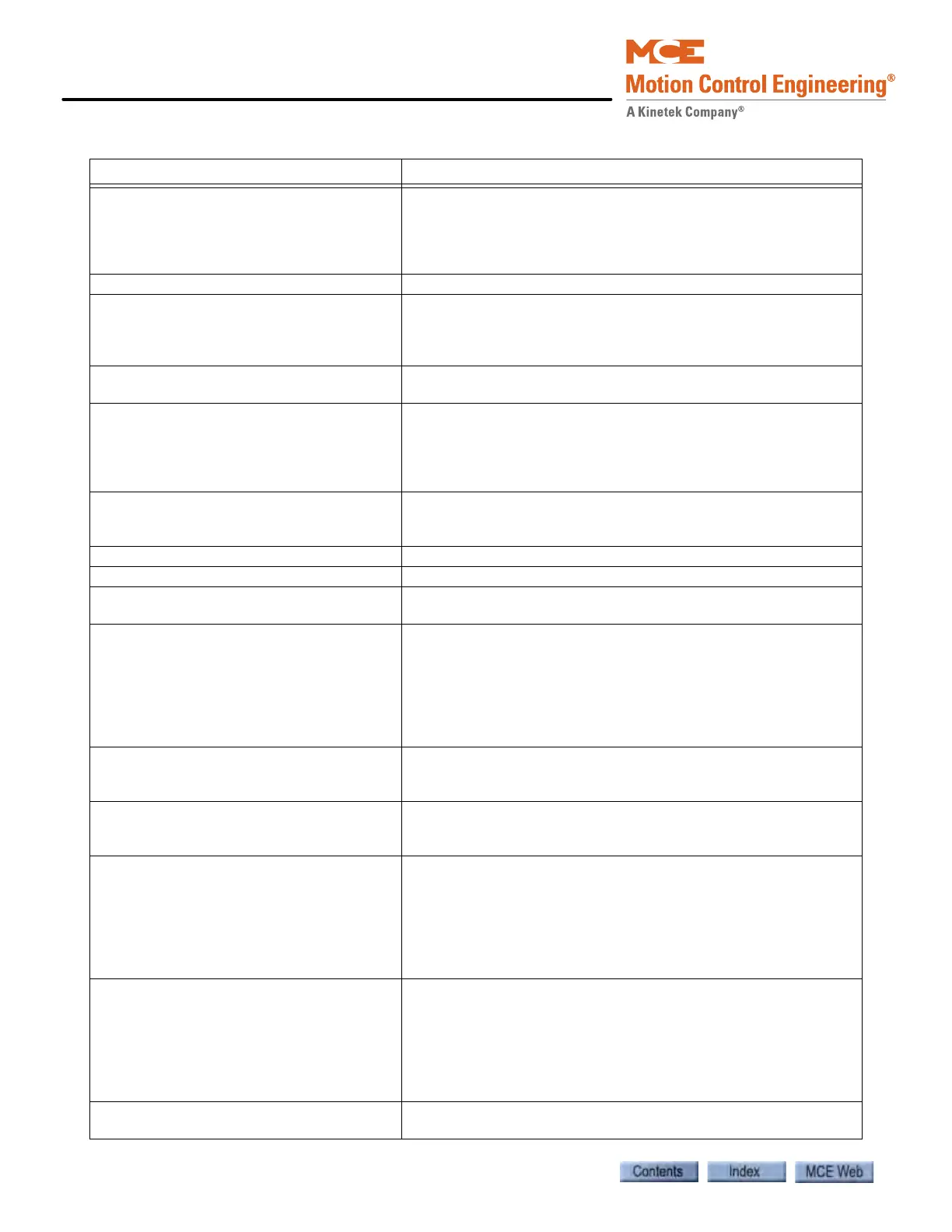

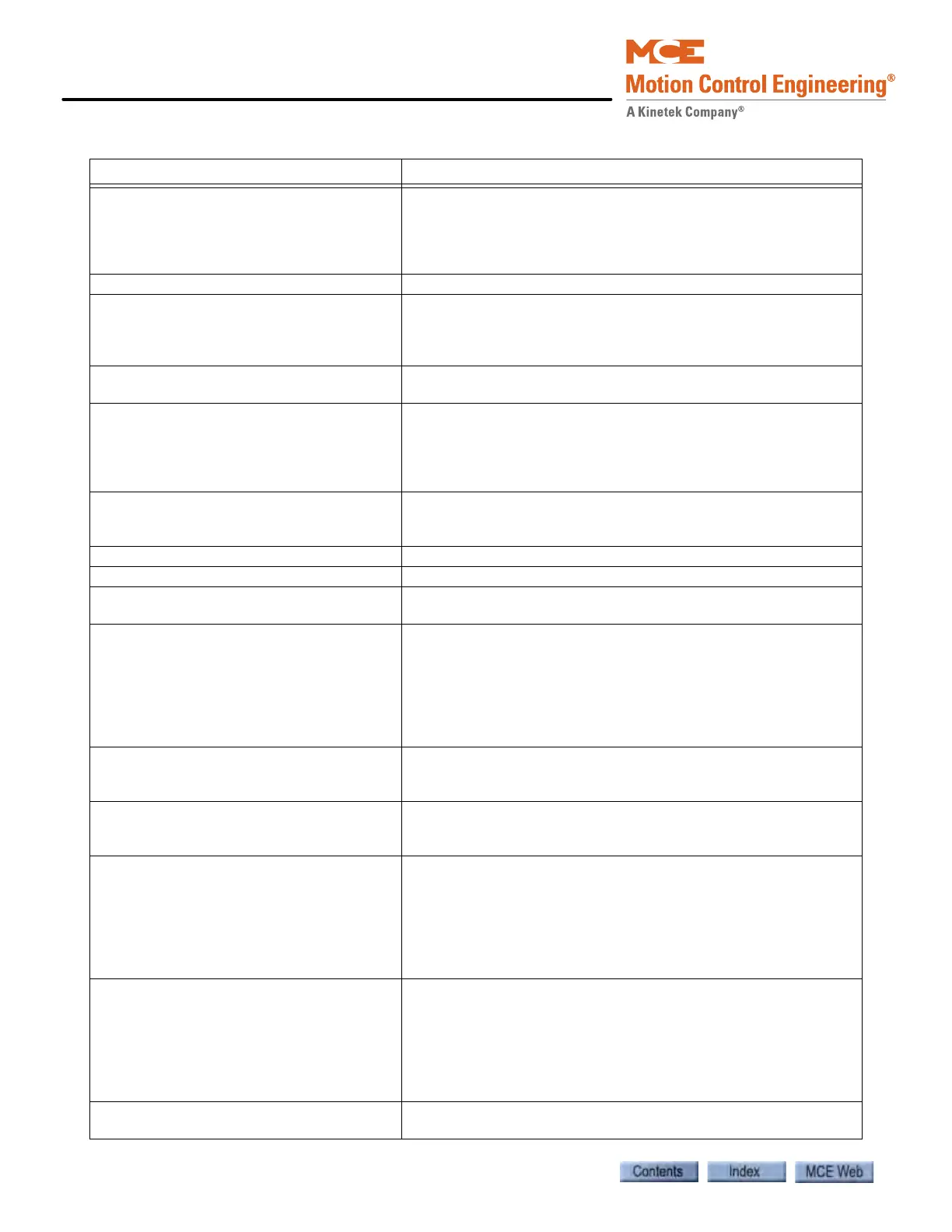

Reference

11-6 Manual # 42-02-7223

Pattern (Region) The numbers reflect a simplified representation of the speed

profile in comparison to Pattern (Phase).

0 = Idle 3 = Deceleration

1 = Acceleration 4 = Flare

2 = Peak 5 = Leveling

Pattern (Slew Limited) Slew rate limited pattern signal.

Position Bit This signal represents car position/motion. It is abstracted from

the motor velocity encoder or tach signal. The signal toggles low

or high with every 32-inches of motor travel. Increasing fre-

quency = increasing rate of position change.

Pre-Run Status High = Pre-energizes motor field as doors are closing and

demand occurs.

Pretorque (Command) This is the actual pretorque signal sent to the drive and used to

pretorque the motor. This is filtered representation of the raw

pretorque “demand” signal, captured as the doors close and

used to pretorque the motor as needed depending on the weight

in the car.

Pretorque (Raw) This is a representation of the raw pretorque “demand” signal. It

will react to car load changes (i.e., doors open, passengers load-

ing/unloading).

SCR Current Sensor Offset Status High = SCR current sensor signal offset positive.

SCR Intg Offset Status High = SCR integrator signal offset positive.

Speed Bit When the car is still, this signal is high. When the car is travel-

ling at a rate in excess of 40fpm, this signal is low.

Speed Feedback Filtered speed feedback signal. Please refer to “Verify Pattern

Command and Drive Speed Feedback” on page 2-67.Please refer

to “Tach Failure Calibration (System 12 SCR Drive)” on page 2-

69. Please refer to “Empty Car Tests” on page 3-31. Please refer

to “Verifying a One Floor Run” on page 4-5. Please refer to “Set-

ting Pattern Parameters” on page 4-19. Please refer to “Tach

Error Tripping Threshold Adjustment” on page 4-47.

Sufficient Field Status High = sufficient motor field current has been achieved. Differ-

ent percentage of forcing, depending on mode. Inspection =

60% of forcing. Other, 80% of forcing.

Synthetic Signal Speed signal synthesized from armature voltage and current.

Please refer to “Tach Failure Calibration (System 12 SCR Drive)”

on page 2-69.

Tach Error Lower Limit This signal represents the lower margin of tach error allowed at

contract speed before a tach fault is generated. Display with

Speed Feedback signal to see the margin. If Speed Feedback

crosses Tach Error Lower Limit the tach fault will be generated.

Please refer to “Tach Error Tripping Threshold Adjustment” on

page 2-68. Please refer to “Tach Error Tripping Threshold Adjust-

ment” on page 4-47.

Tach Error Upper Limit This signal represents the upper margin of tach error allowed at

contract speed before a tach fault is generated. Display with

Speed Feedback signal to see the margin. If Speed Feedback

crosses Tach Error Upper Limit the tach fault will be generated.

Please refer to “Tach Error Tripping Threshold Adjustment” on

page 2-68. Please refer to “Tach Error Tripping Threshold Adjust-

ment” on page 4-47.

Tachometer Signal Raw tachometer signal. Please refer to “Speed Loop Gains (Sys-

tem 12 SCR Drive)” on page 2-66.

Table 11.2 Test Point Signals

Test Signal Description / Text References

Loading...

Loading...