Make sure that the splice has the smallest CAU range that can accept the total CAU of the

conductor.

(4) Find the crimp barrel size of the splice from Table 15.

(5) Make a selection of a crimp tool from Table 46.

(6) Make a selection of a Temperature Grade D insulation tape from Table 52.

Make sure that the tape has a width of 0.5 inch minimum to 1.0 inch maximum.

(7) Prepare each wire for the side of the splice assembly with two wires.

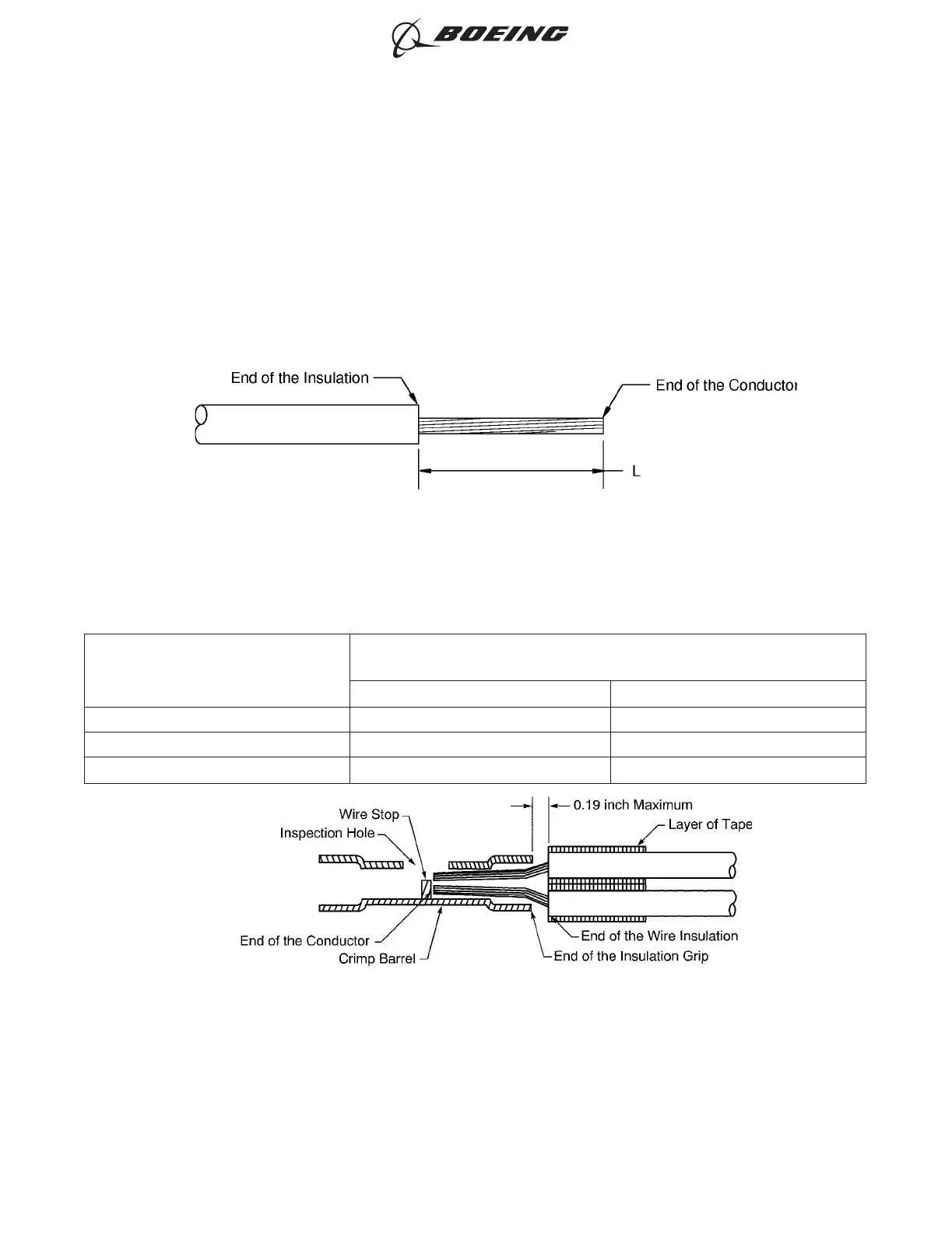

Table 97

INSULATION REMOVAL LENGTH

Splice Part Number

Insulation Removal Length L

(inch)

Target Tolerance

BACT12C11 0.46 ±0.02

BACT12C15 0.30 ±0.02

BACT12C20 0.30 ±0.02

(a) Remove the necessary length of insulation from the end of each wire.

Refer to:

INSULATION REMOVAL LENGTH

Figure 138

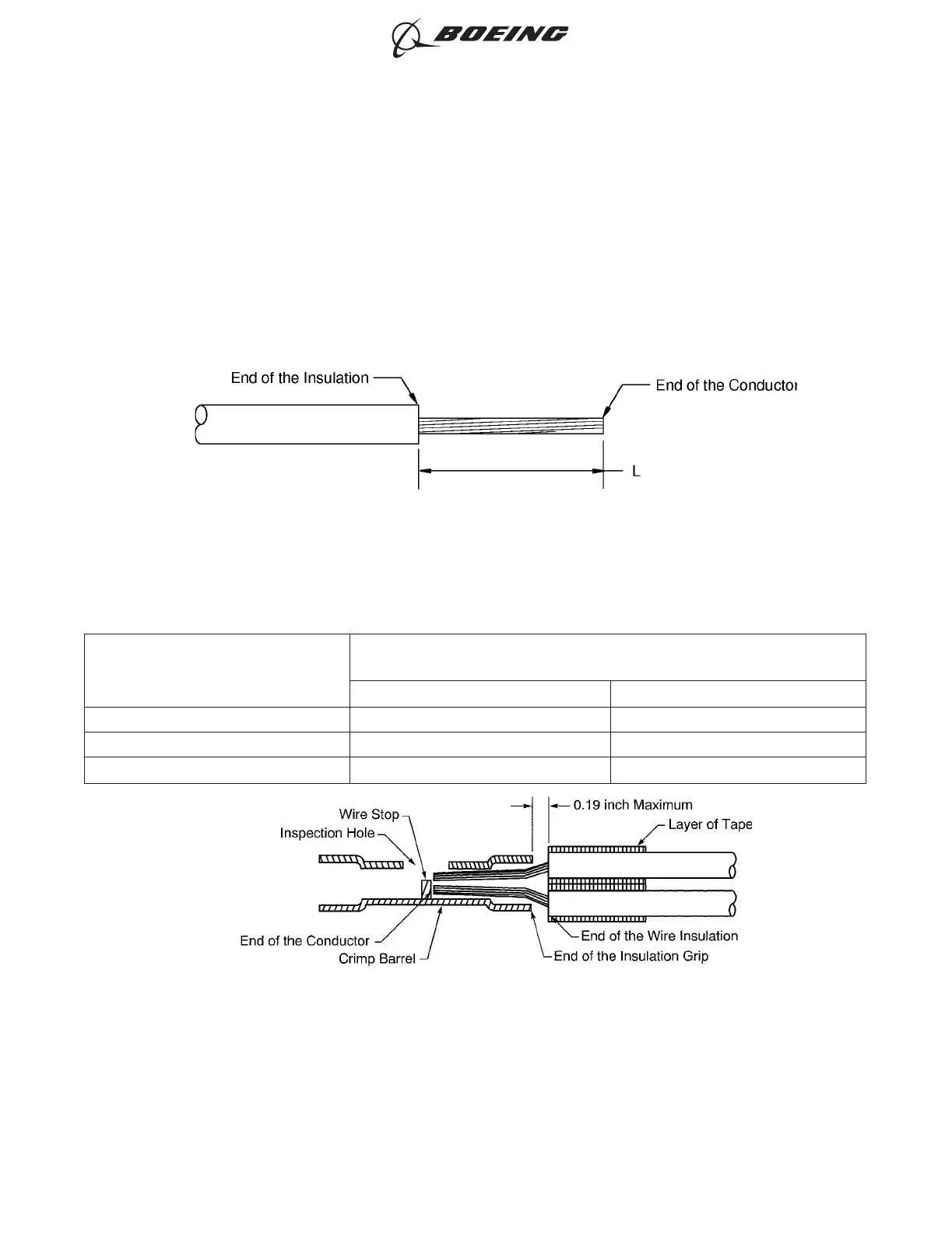

POSITION OF THE WIRES IN THE BUTT SPLICE

Figure 139

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 163

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...