• Figure 138

• Table 97 for the insulation removal length

• Subject 20-00-15 for the insulation removal procedures.

(b) Put the wires in the splice. Refer to Figure 139.

Make sure that:

• The end of each conductor can be seen in the inspection hole

• The end of each conductor does not make an overlap with the wire stop

• The end of each wire insulation is a maximum of 0.19 inch from the end of the

insulation grip.

(c) If it is necessary, remove more insulation from the end of the wire.

(d) Wind a layer of the insulation tape on each wire. Refer to Figure 139.

Make sure that:

• The edge of the tape is aligned with the end of the wire insulation

• The tape goes around the circumference of the wire a minimum of two times

• The tape makes a 100 percent overlap.

(8) Remove the necessary length of insulation from the end of the wire for the side of the splice

assembly with one wire.

Refer to:

• Figure 138

• Table 98 for the insulation removal length for a wire that can go into the insulation grip

• Table 99 for the insulation removal length for a wire that cannot go into the insulation grip

• Subject 20-00-15 for the insulation removal procedures.

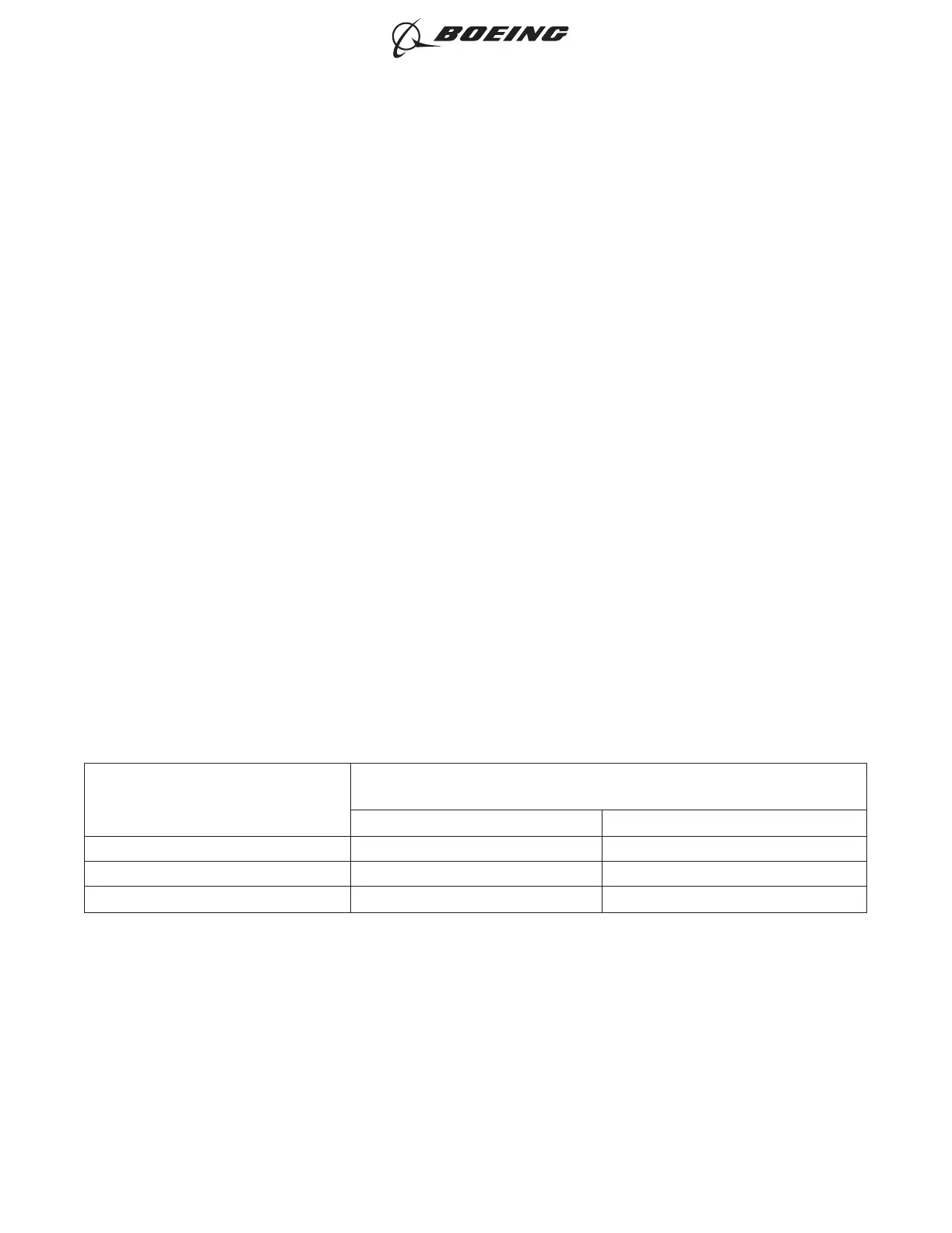

Table 98

INSULATION REMOVAL LENGTH FOR A WIRE THAT CAN GO INTO THE INSULATION GRIP

Splice Part Number

Insulation Removal Length L

(inch)

Target Tolerance

BACT12C11 0.37 ±0.02

BACT12C15 0.23 ±0.02

BACT12C20 0.23 ±0.02

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 164

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...