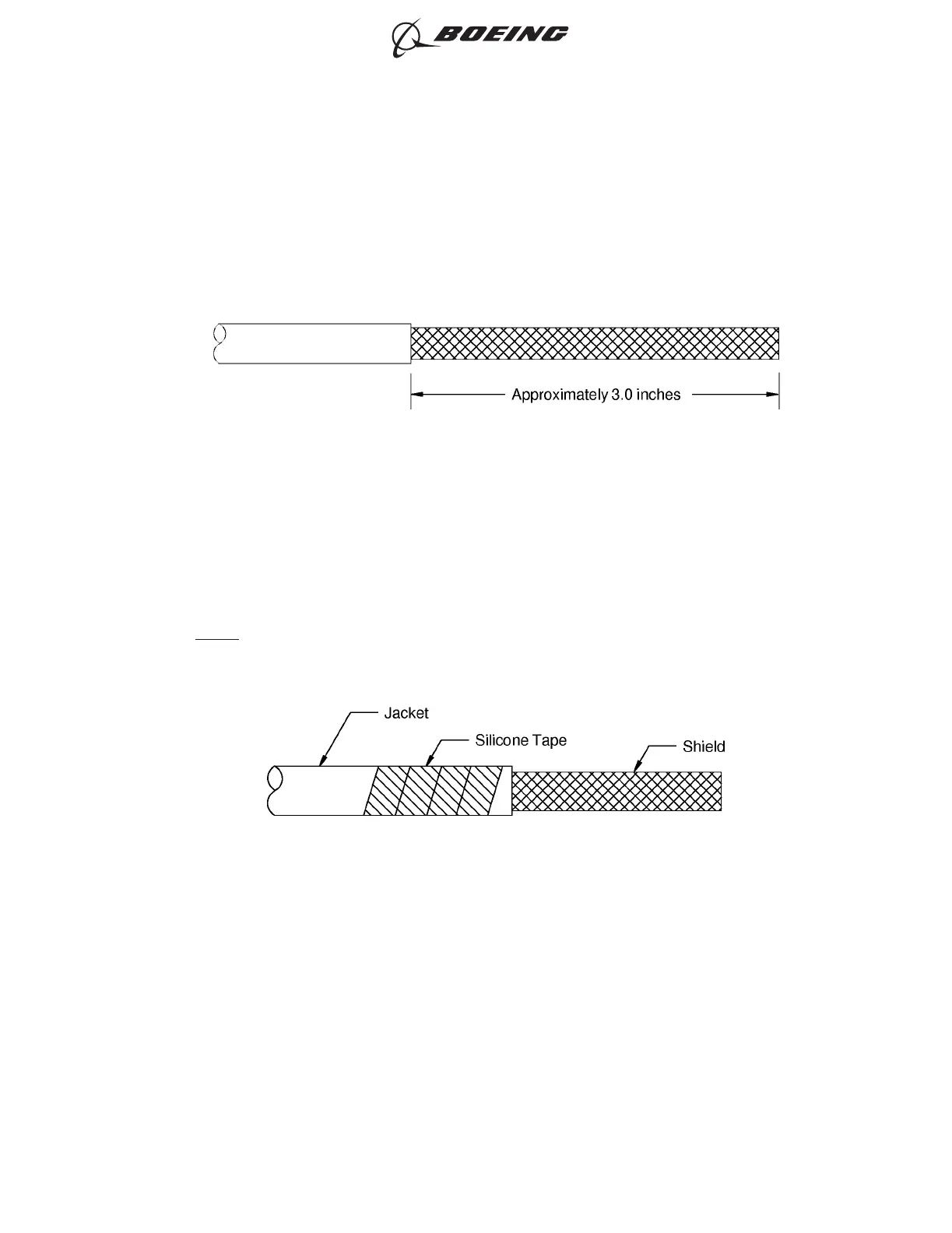

(2) Remove approximately 3 inches of the outer jacket from the end of the wire on each side of the

repair location.

Refer to:

• Figure 210

• Subject 20-00-15 for the outer jacket removal procedures.

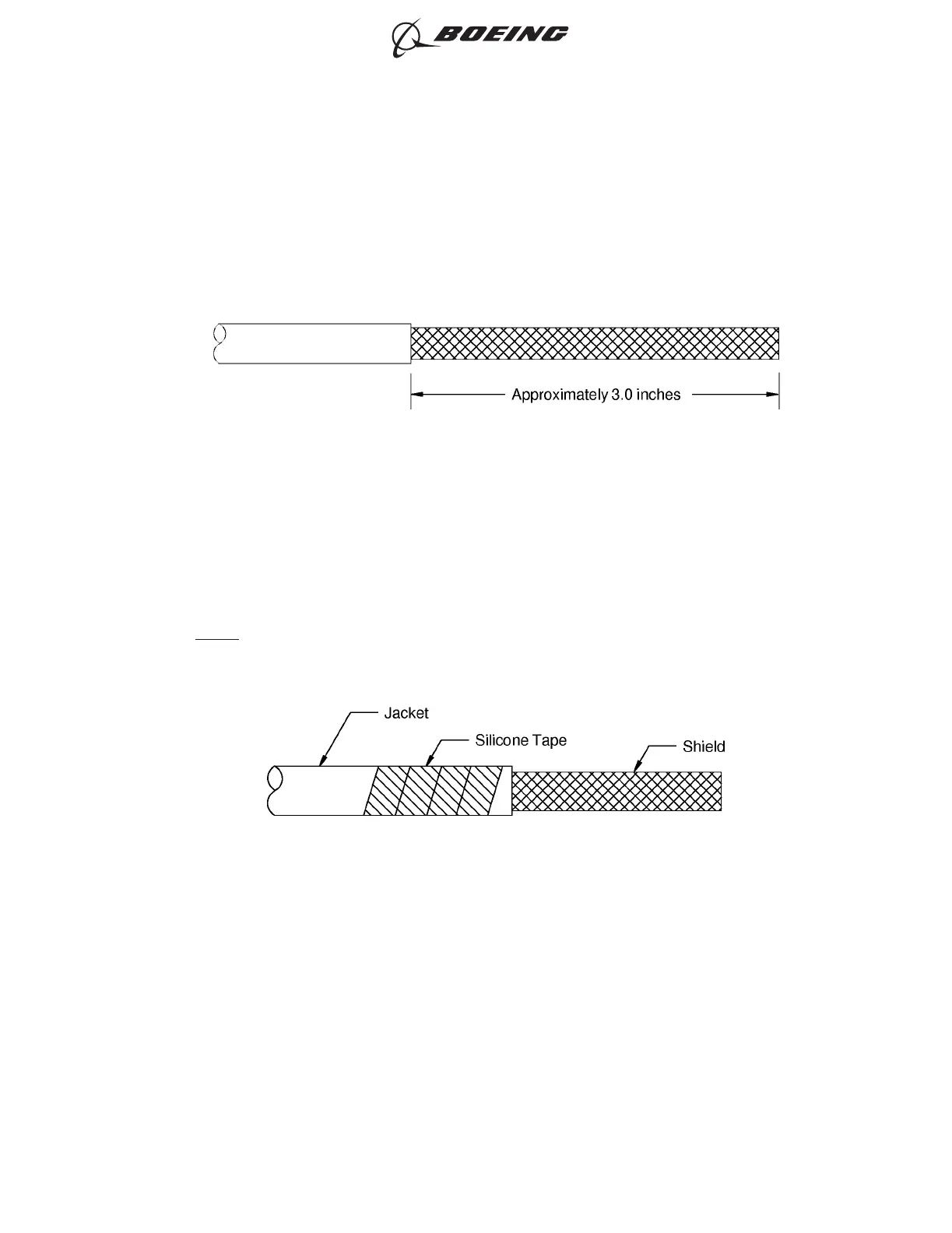

(3) Wrap a minimum of one layer of Temperature Grade D Type I silicone tape on each side of the

repair location on the each cable jacket near the end of the jacket where the shield termination

ring will be located.

Refer to Figure 212 and Figure 211.

NOTE: Additional wraps of silicone tape tape may be necessary on the jacket to give a proper fit

for the shield termination ring.

(4) Put a shield termination ring on the jacket of the wire on each side of the repair location. Refer to

Figure 211.

Make sure that the distance from the end of the jacket to the forward edge of the shield terminator

band is approximately 0.25 inch.

SHIELDED WIRE PREPARATION

Figure 210

POSITION OF THE SILICONE TAPE ON THE JACKET OF THE SHIELDED WIRE

Figure 211

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 251

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...