(13) Align the ends of the shield sleeve material with the ends of the cable jacket.

(14) If it is necessary, trim the length of the shield sleeve material to make a fit between the ends of

the jacket.

(15) Assemble one end of the shield splice.

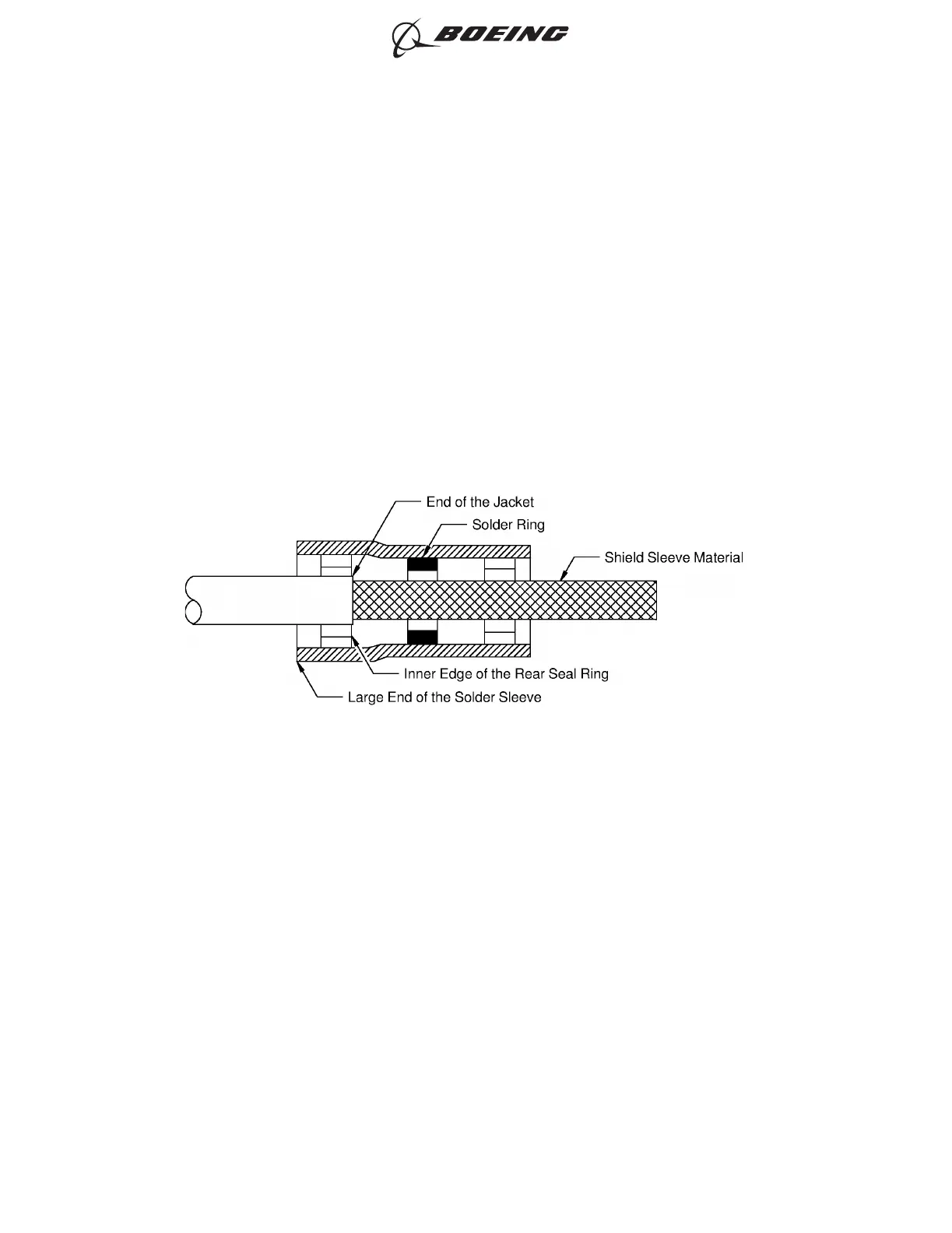

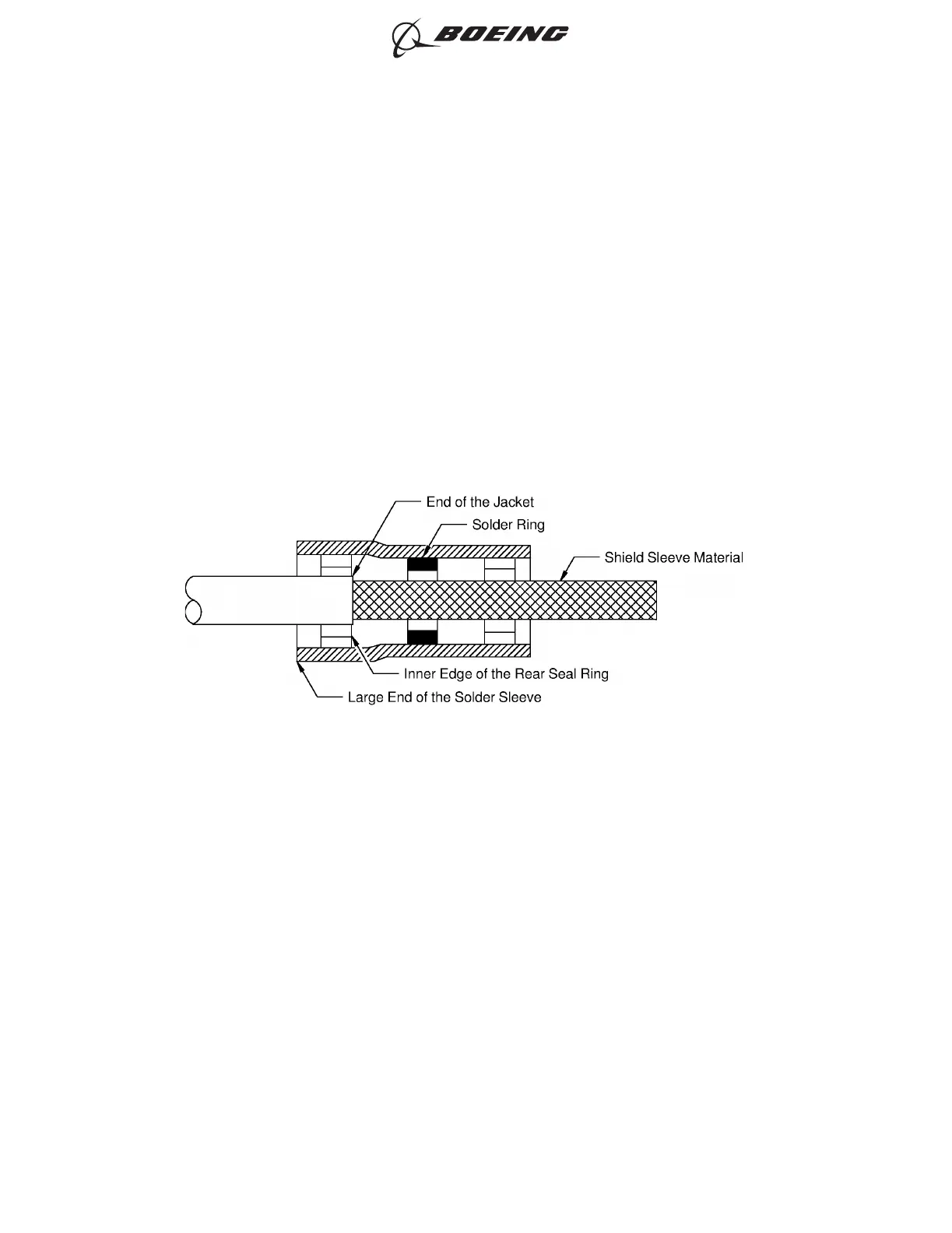

(a) Move the solder sleeve on the jacket and the shield sleeve material. Refer to Figure 297.

Make sure that:

• The end of the shield sleeve material is a maximum of 0.1 inch from the end of the

jacket

• The inner edge of the rear seal ring is aligned with the end of the jacket

• The seal ring does not make an overlap with the shield.

(b) Shrink the solder sleeve into its position.

Make sure that:

• The solder sleeve stays in the correct position

• A minimum of 75 percent of the indicator ring on top of the solder ring is melted.

(16) Do Step 15.B.(15) again to assemble the other end of the shield splice.

Make sure that the shield sleeve material is pulled tight before the splice is assembled.

(17) Tightly wind a layer of the tape on the splice assembly.

Make sure that the layer of tape:

• Starts 0.50 inch ±0.25 inch farther than the rear end of the solder sleeve at one end of the

splice

POSITION OF THE SOLDER SLEEVE ON THE shield sleeve material

Figure 297

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 334

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...