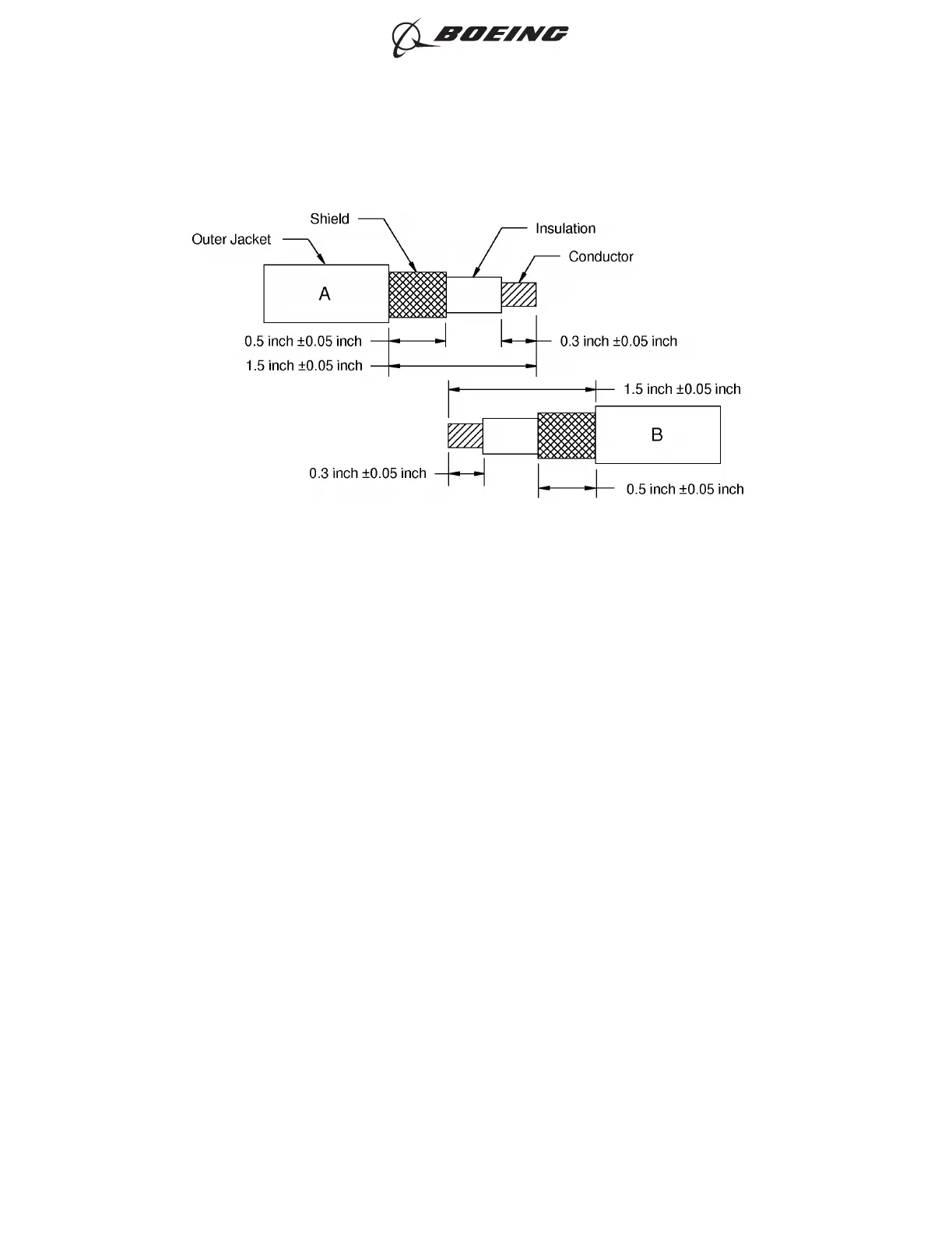

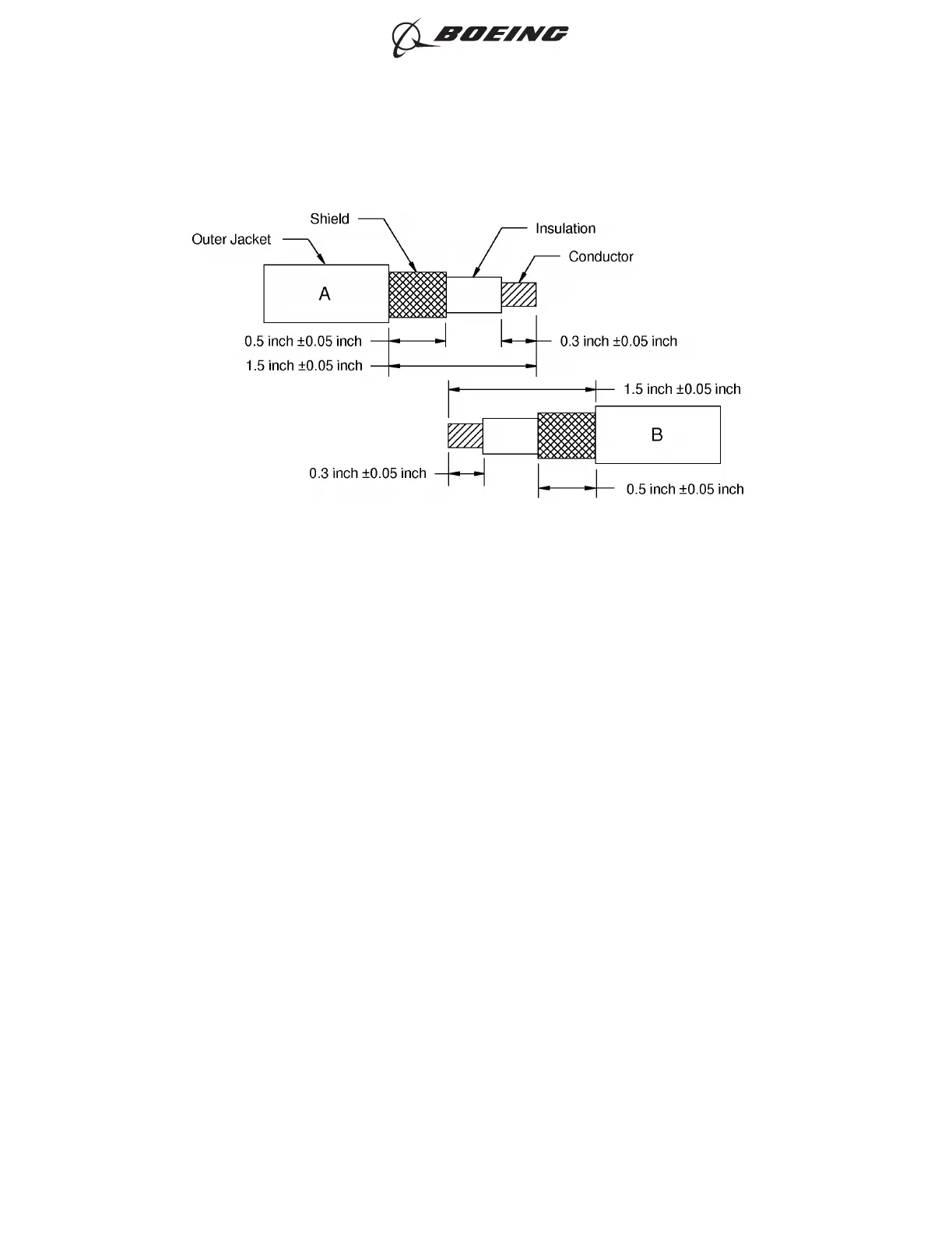

(a) Remove 1.50 inches ±0.05 inch of the outer jacket from the end of the cable.

(b) Remove the necessary length of the shield so that the distance from the end of the shield to

the end of the outer jacket is 0.50 inch ±0.05 inch.

(c) Remove the necessary length of the insulation so that the distance from the end of the

insulation to the end of the conductor is 0.30 inch ±0.05 inch.

(2) Remove a short length of each end of the shield tube so that the diameter of the tube can be

increased.

(3) In this order, put these components on Cable A:

• The outer sleeve

• A solder sleeve

• The shield tube.

(4) In this order, put these components on Cable B:

• A solder sleeve

• The seal sleeve.

(5) Assemble the Cable A end of the splice:

(a) Put the conductor in the splice so that the end of the conductor is aligned with the center of

the splice.

(b) Crimp the splice.

(6) Do Step 16.B.(5) again for the Cable B end of the splice.

CABLE PREPARATION

Figure 299

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 338

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...