(2) If the conductor splice has a seam, put the seam on the same side as the indenter.

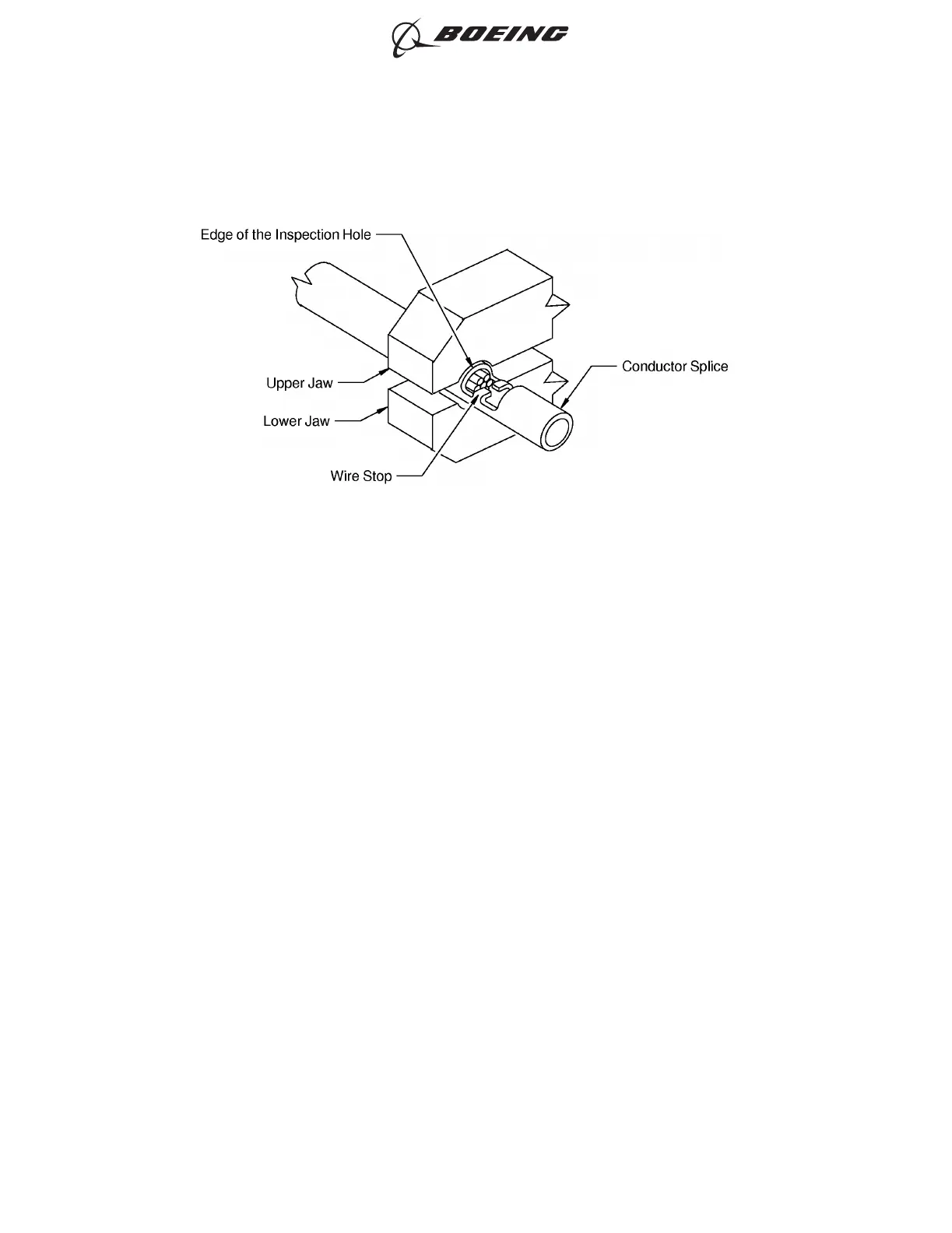

(3) Slowly close the jaws of the tool until the splice is held in position.

(4) If it is necessary, adjust the position of the conductor splice in the crimp tool to make sure that the

crimp occurs on correct location on the crimp barrel.

(5) Put the necessary conductors in one end of the conductor splice. Refer to Figure 47.

Make sure that the end of each conductor is against the wire stop in the center of the conductor

splice.

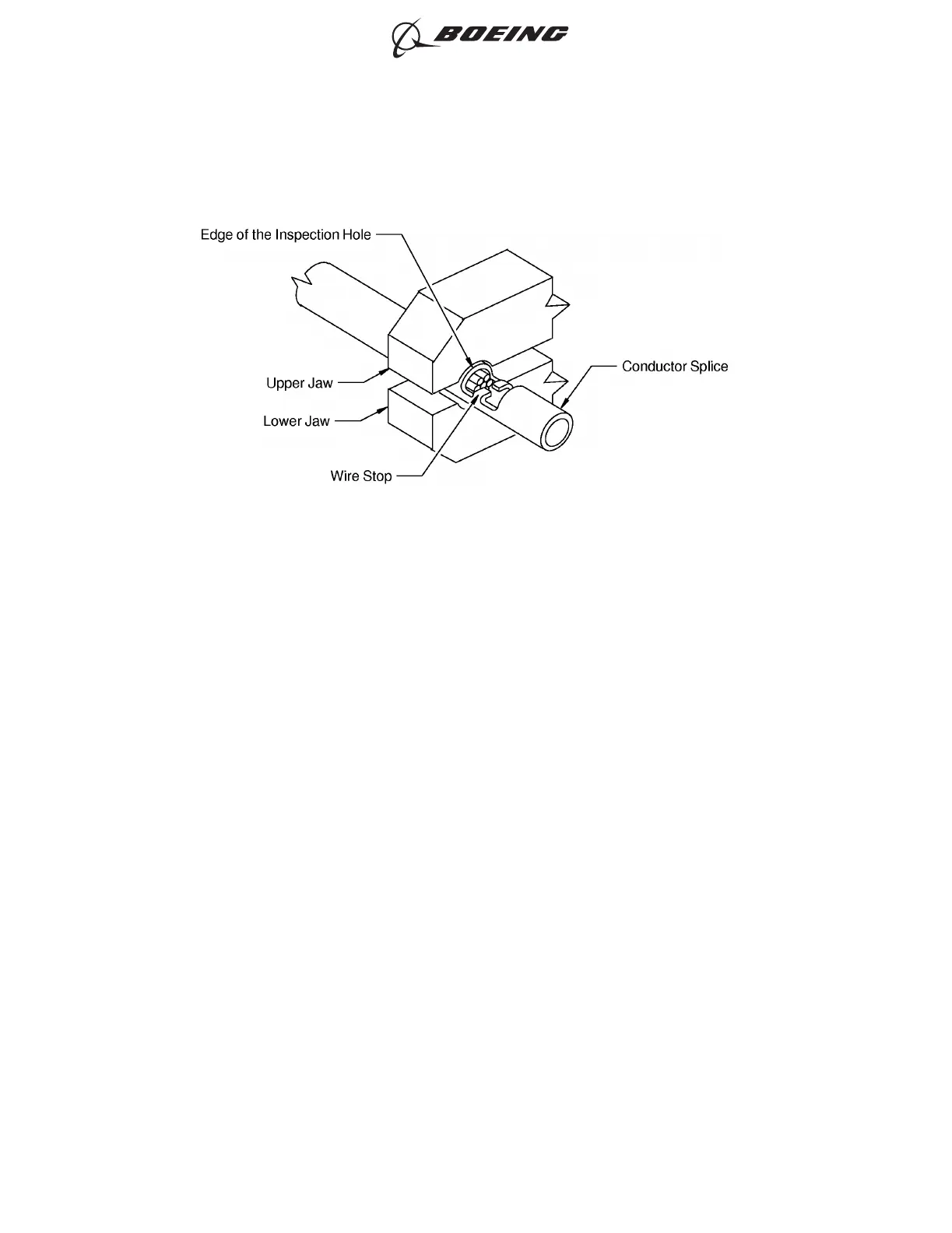

(6) If a filler wire is specified, remove the unwanted length of the filler wire to make the distance from

the end of the crimp barrel to the end of the filler wire equal to 0.06 inch or shorter. Refer to

Figure 48.

POSITION OF THE CONDUCTOR SPLICE IN THE CRIMP TOOL

Figure 47

ASSEMBLY OF BACS52P SERIES AND D-150-0300 SERIES SHIELDED SPLICE ASSEMBLIES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-20

Page 175

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...