CAUTION

UNEVEN PRESSURE OR A STRONG FORCE MUST NOT BE APPLIED TO

THE TONGUE OF THE TERMINAL LUG. THE DAMAGE CAN CAUSE

UNSATISFACTORY PERFORMANCE OF THE LUG ASSEMBLY.

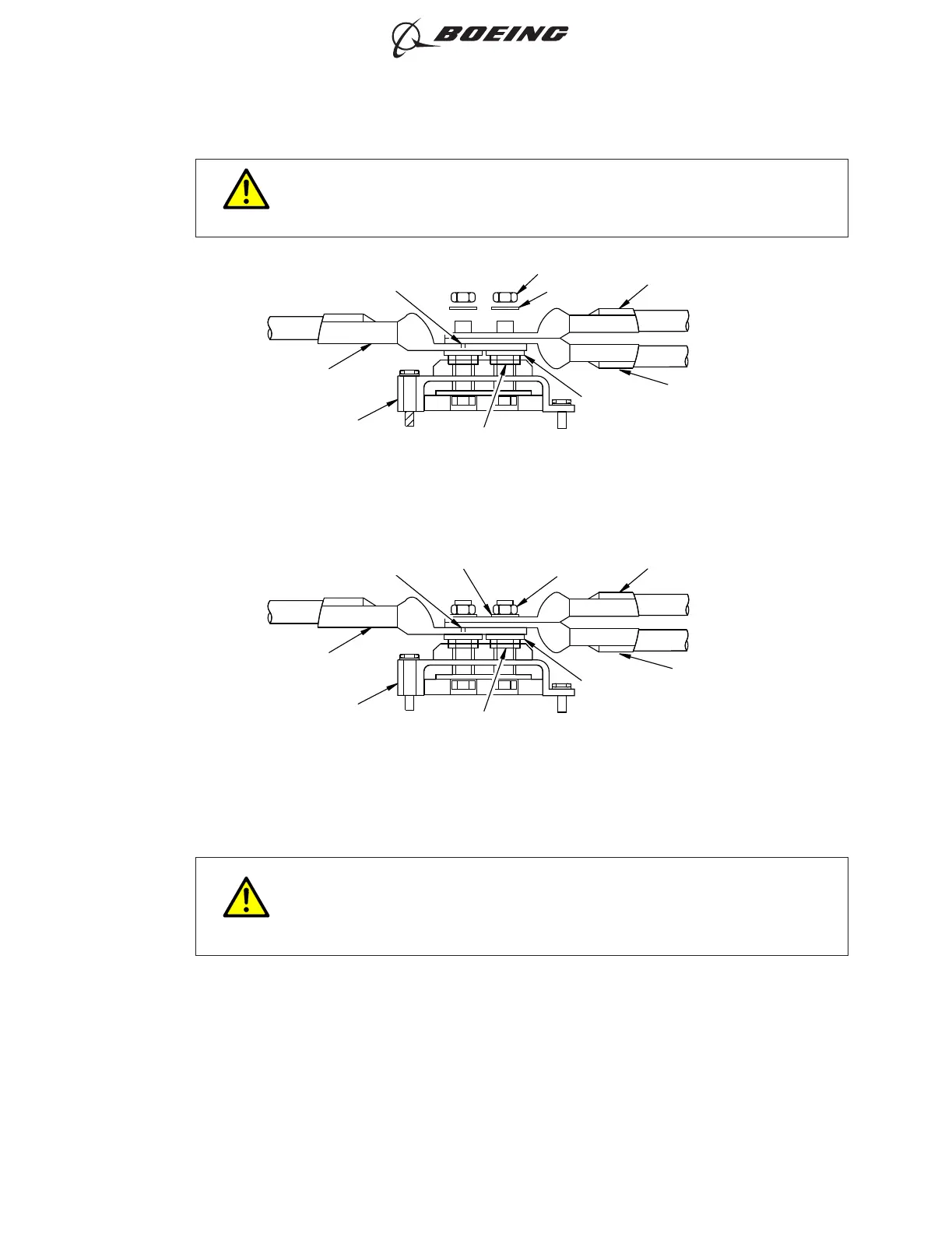

(7) Put a washer and a nut on each stud. Refer to Figure 21.

(8) Torque each nut 200 inch-pounds to 240 inch-pounds.

(9) Examine the breakaway terminal lug assembly. Refer to Figure 16 and Figure 17.

CAUTION

IF THE TONGUE OF A BACT13T TERMINAL LUG HAS A BEND THAT IS

MORE THAN 0.15 INCH FROM THE LONGITUDINAL AXIS OF THE

BOTTOM SURFACE OF THE TONGUE, DO NOT TRY TO MAKE THE

TONGUE STRAIGHT. THE TERMINAL LUG IS DAMAGED AND MUST BE

REPLACED.

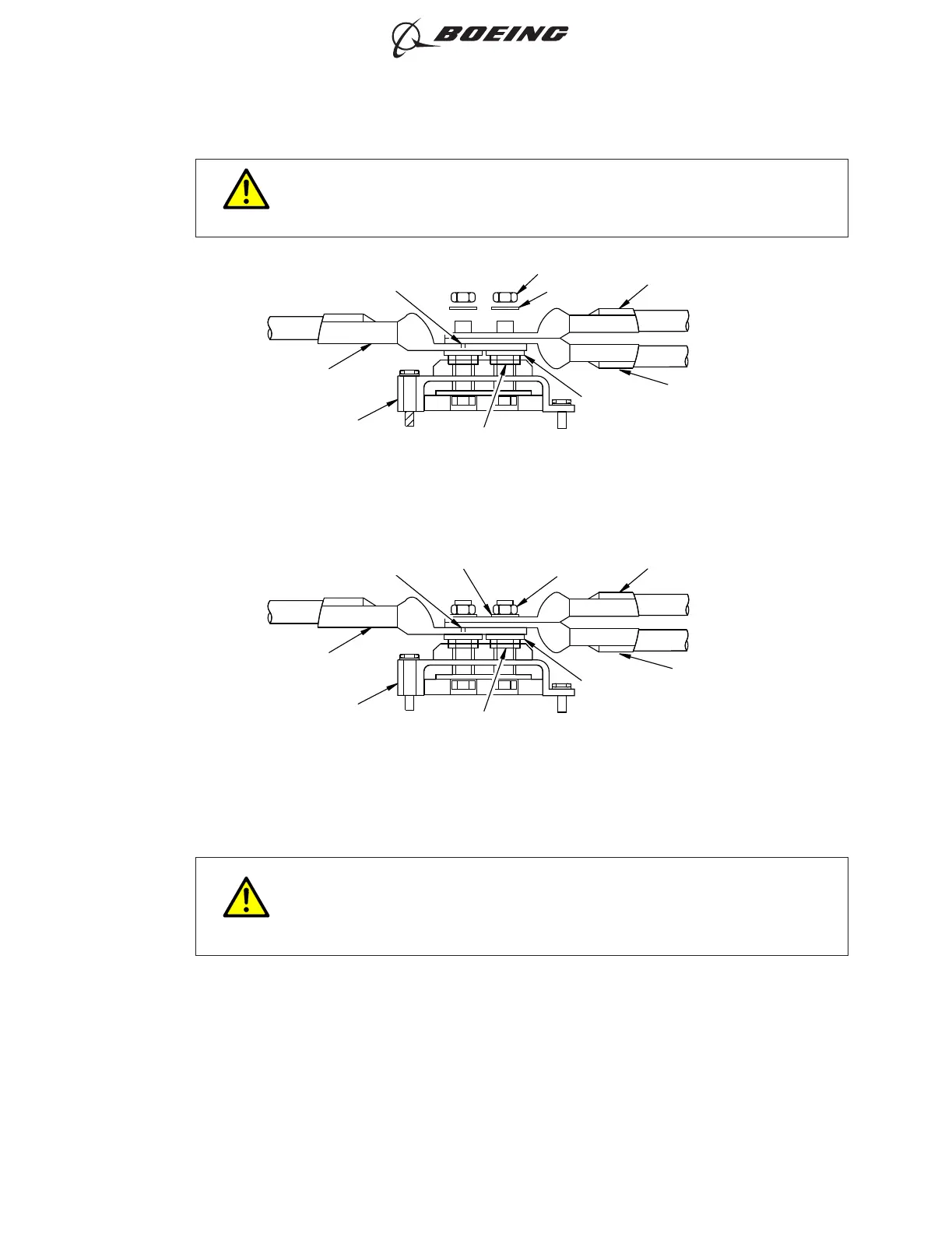

BREAKAWAY AREA

WASHER

WASHER

TERMINAL BOARD

BREAKAWAY

TERMINAL LUG

JAM NUT

NUT

COPALUM TYPE

TERMINAL LUG

COPALUM TYPE

TERMINAL LUG

2449207 S00061545389_V3

POSITION OF THE TWO TERMINAL LUG ASSEMBLIES

Figure 20

BREAKAWAY AREA

WASHER

WASHER

TERMINAL BOARD

BREAKAWAY

TERMINAL LUG

JAM NUT

NUT

COPALUM TYPE

TERMINAL LUG

COPALUM TYPE

TERMINAL LUG

2449208 S00061545390_V3

POSITION OF THE NUTS AND WASHERS

Figure 21

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 23

Oct 15/2018D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...