(c) Hold the splice in position with light pressure.

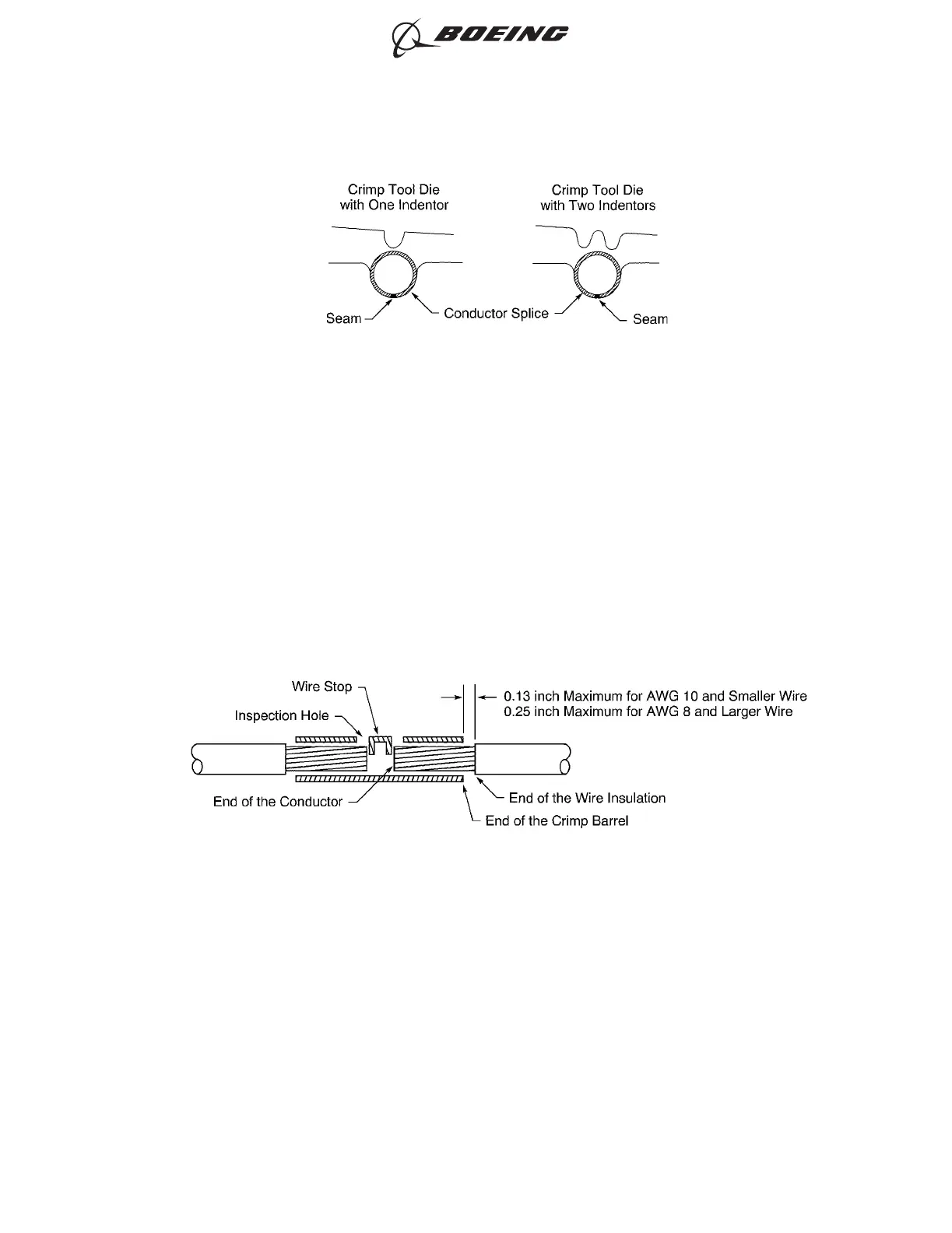

(d) Put the wire in the splice. Refer to Figure 45.

Make sure that:

• The end of the conductor can be seen in the inspection hole

• The end of the conductor does not make an overlap with the wire stop

• The insulation of the wire is not in the crimp barrel

• For an AWG 10 and smaller wire, the end of the wire insulation is a maximum of 0.13

inch from the end of the crimp barrel

• For an AWG 8 and larger wire, the end of the wire insulation is a maximum of 0.25

inch from the end of the crimp barrel.

(e) Crimp the splice.

(10) Do Step 7.C.(9) again to assemble the other end of the butt splice.

(11) Apply a continuous layer of the sealant on the area of the splice. Refer to Figure 46.

Make sure that:

• The splice has a full layer of sealant on the length and the circumference of the splice

surface

• The sealant extends a minimum of 1.5 inches farther than each end of the splice.

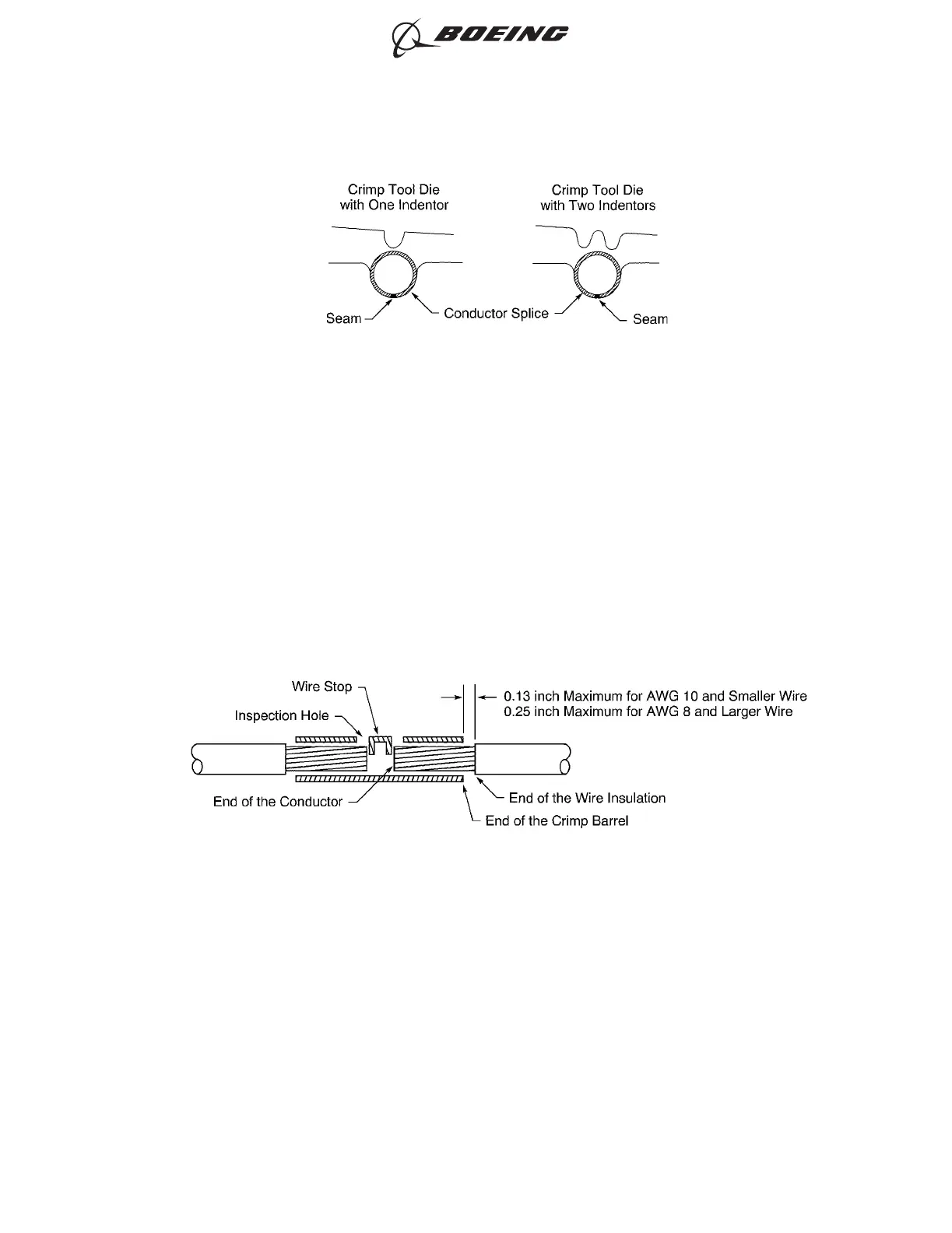

POSITION OF THE BUTT SPLICE IN THE CRIMP TOOL

Figure 44

POSITION OF THE WIRE IN THE BUTT SPLICE

Figure 45

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 86

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...