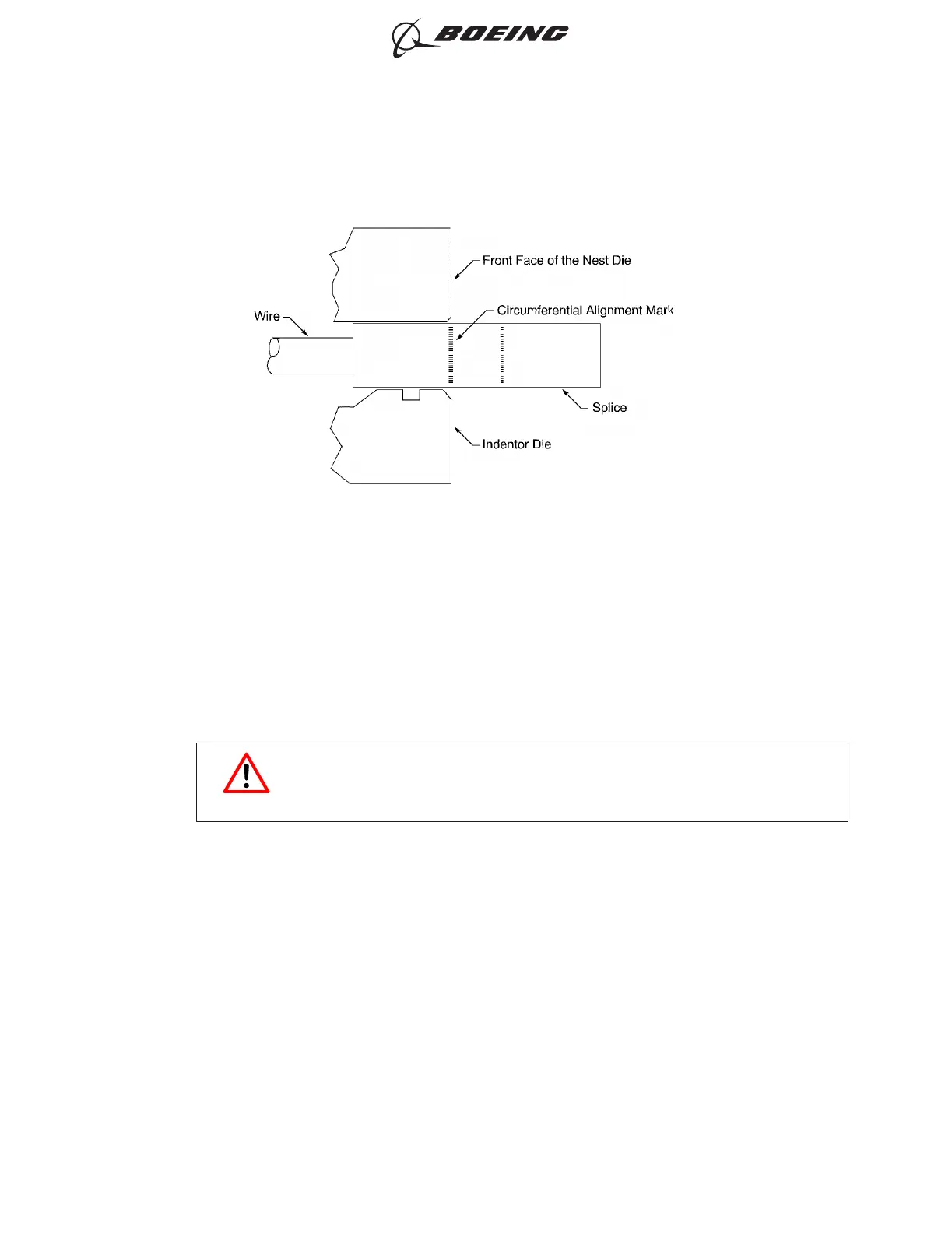

(a) Align the center of the circumferential splice crimp alignment mark with the edge of the nest

die.

(b) Align the longitudinal crimp alignment mark with the alignment dot on the nest die.

(10) Crimp the splice.

Make sure that the alignment of the splice in the die does not change.

WARNING

KEEP HANDS AWAY FROM THE DIES WHEN THE CRIMP TOOL IS

ACTIVATED. INJURY TO PERSONNEL CAN OCCUR.

(11) Remove the splice from the crimp tool.

(12) Remove all the flash and the sharp edges on the splice.

(13) Examine the splice.

Make sure that:

• The edge of the mold line from the die is between the ends of the circumferential alignment

mark on the splice; refer to Figure 11

• The side of the splice with the longitudinal alignment mark is opposite the side of the splice

with the certification mark

• The certification mark can be seen in the bottom and the center of the crimp dent; refer to

Figure 12

• The certification mark is a clearly formed, cylindrical button; refer to Figure 13

POSITION OF THE SPLICE IN THE CRIMP TOOL - SIDE VIEW

Figure 10

ASSEMBLY AND REPAIR OF THE AMP AND BACS52N COPALUM SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-13

Page 24

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...