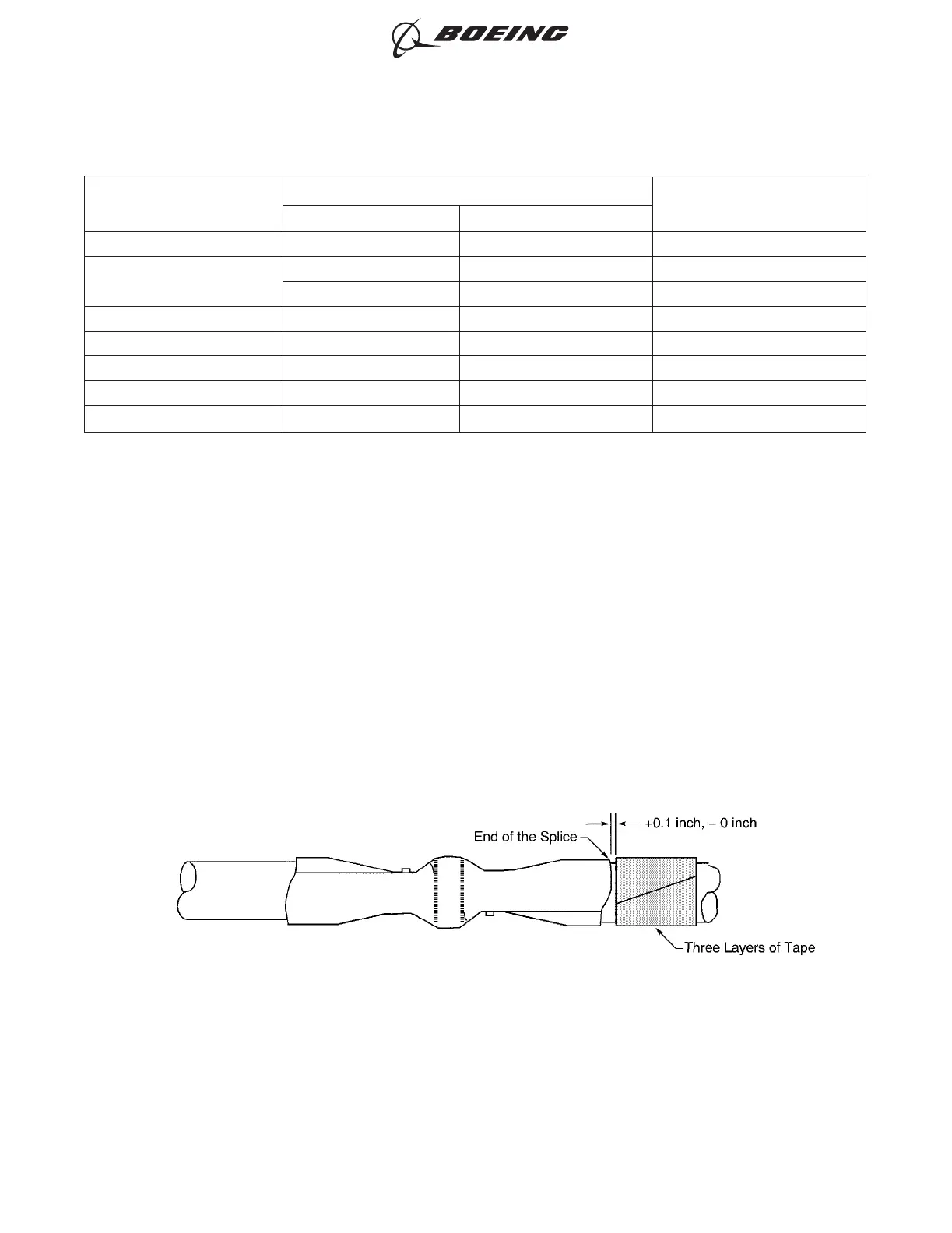

Table 20 BACS52N SPLICES THAT MUST HAVE LAYERS OF BUILDUP TAPE (Continued)

Splice

Wire Size(AWG)

Layers of Tape

First Splice End Second Splice End

BACS52N-5A78 1/0 2 0

BACS52N-6

2/0 1/0 0

1/0 1/0 0

BACS52N-6A78 2/0 1/0 0

BACS52N-7 3/0 2/0 0

BACS52N-7A78 3/0 2/0 0

BACS52N-8 4/0 3/0 0

BACS52N-8A78 4/0 3/0 0

(1) Make a selection of a solvent from Table 7.

(2) With a clean wiper and solvent, clean the splice and a minimum of two inches of the wire from

each end of the splice.

(3) Dry the clean area with a clean wiper.

(4) Find if layers of tape are necessary to fill the area between the cold shrink sleeve and the wire

insulation. Refer to Table 19 for AMP splices and Table 20 for BACS52N splices.

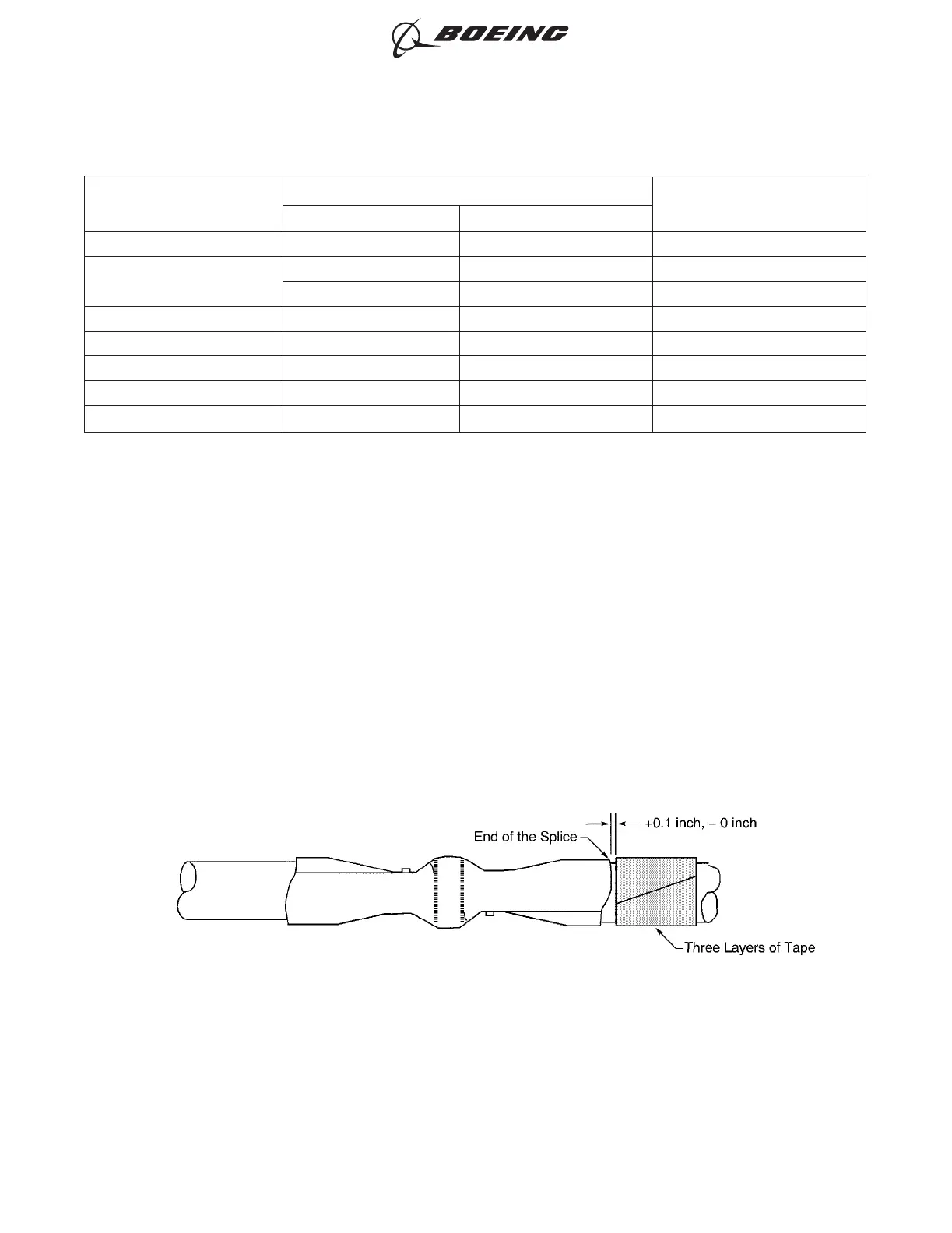

(5) If layers of buildup tape are necessary to fill the area between the cold shrink sleeve and the wire

insulation, install a minimum of three layers of tape on the wire insulation.

(a) Make a selection of an insulation tape from Table 7.

(b) Wind three layers of tape on the wire insulation at one end of the splice. Refer to Figure 22.

Make sure that:

• The end of the layer of tape is a maximum of 0.1 inch from the end of the splice

• The layers of tape do not make an overlap with the splice

• The layers of tape have 100 percent overlap.

(c) Wind three layers of tape on the wire insulation at the other end of the splice. Refer to

Figure 23.

POSITION OF THE LAYERS OF TAPE ON THE WIRE

Figure 22

ASSEMBLY AND REPAIR OF THE AMP AND BACS52N COPALUM SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-13

Page 33

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...