(m) If the crimp area has flash that is caused by the crimp operation:

1) Make a selection of a file from Table 7/Necessary Tools.

2) Remove the flash with the file.

Make sure that the width of the filed area is not more than 0.125 inch.

3) Remove the filings from the assembly.

(n) If the crimp area has flaked plating that is caused by the crimp operation, remove the flaked

plating.

(4) Insulation of the Terminal Lug Assembly - Heat Shrinkable Sleeve

(a) Make a selection of these materials from Table 1/Terminal Lug Assembly Materials.

1) A wiper.

2) A solvent.

(b) Clean the terminal lug and a minimum of 2 inches of the wire insulation from the end of the

crimp barrel of the terminal lug.

(c) Dry the cleaned area with a wiper.

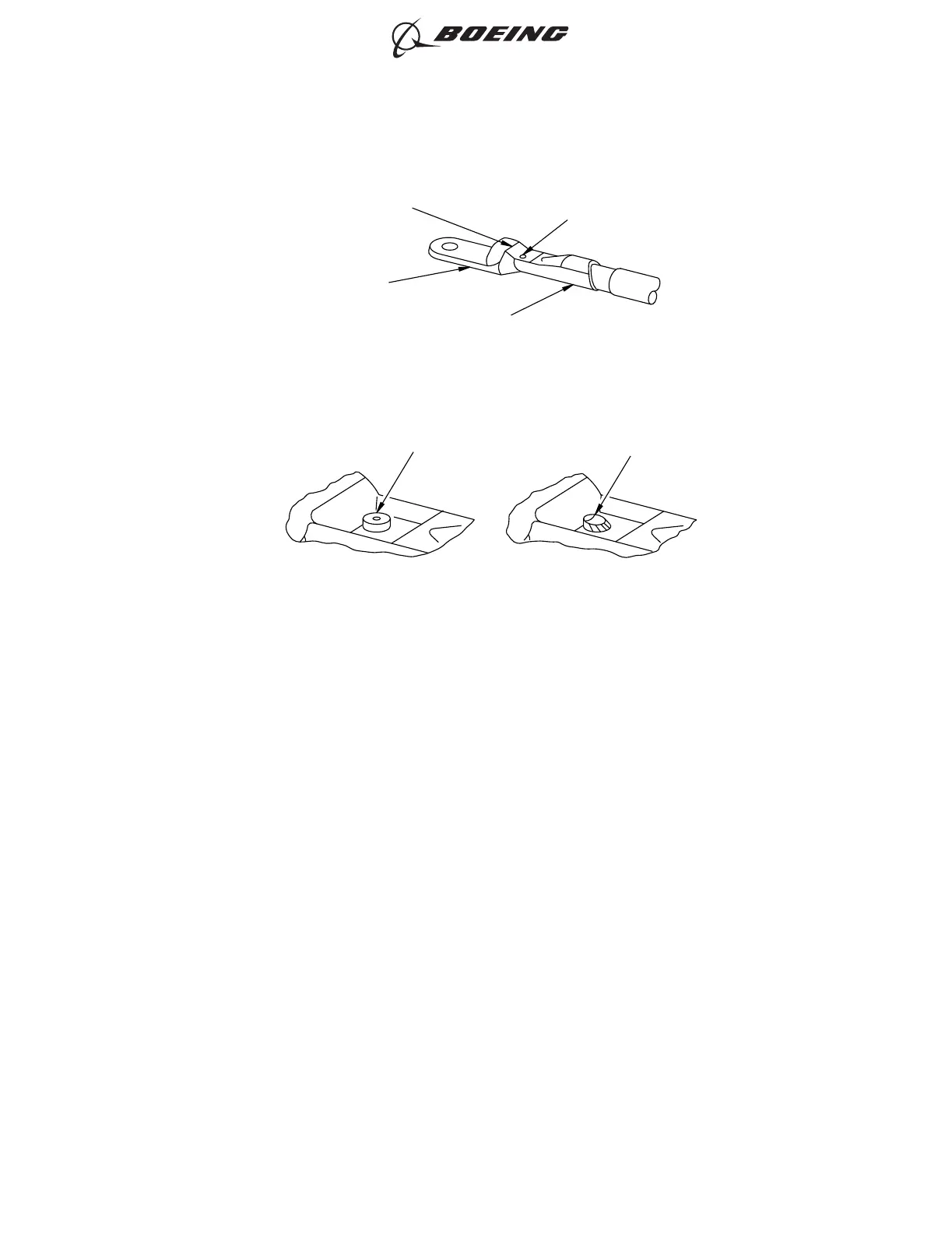

(d) Push the sleeve forward until the forward end of the sleeve is aligned with the rear end of

the tongue of the terminal lug. Refer to Figure 10.

CERTIFICATION

MARK

INDENT AREA

TONGUE

CRIMP BARREL

2528867 S0000597225_V1

Location of the Certification Mark

Figure 8

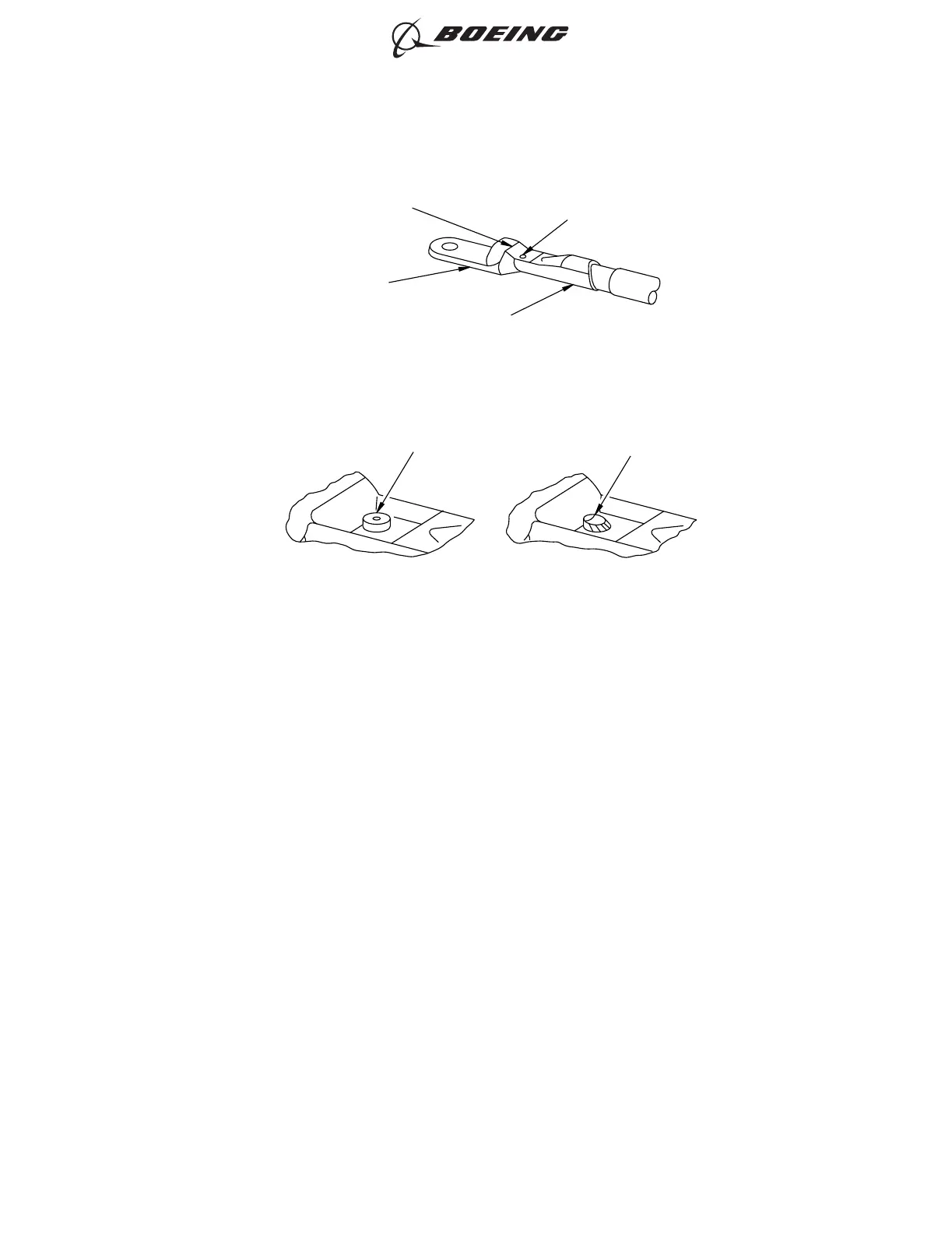

PAP

PAP

SATISFACTORY UNSATISFACTORY

2528868 S0000597226_V1

Formation of the Certification Mark in the Indent Area

Figure 9

ASSEMBLY OF BACT12BC TE ALUMINUM TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-08

Page 9

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...