(1) Make a selection of a butt splice from Table 12 or Table 14.

Make sure that the splice has the smallest CAU range that can accept the total CAU of the

conductor.

Refer to Paragraph 1.D. for the procedure to calculate the CAU of the conductor.

(2) Find the crimp barrel size of the splice from Table 12 or Table 14.

(3) Make a selection of a crimp tool from:

• Table 43 for BACT12C() splices

• Table 44 for NAS1387-() splices

• Table 45 for BACS52K() splices

• Table 45 for Raychem D-609-0() splices.

(4) Make a selection of a Temperature Grade B or higher insulation tape from Table 52.

(5) Remove the necessary length of insulation from the end of each wire.

Refer to:

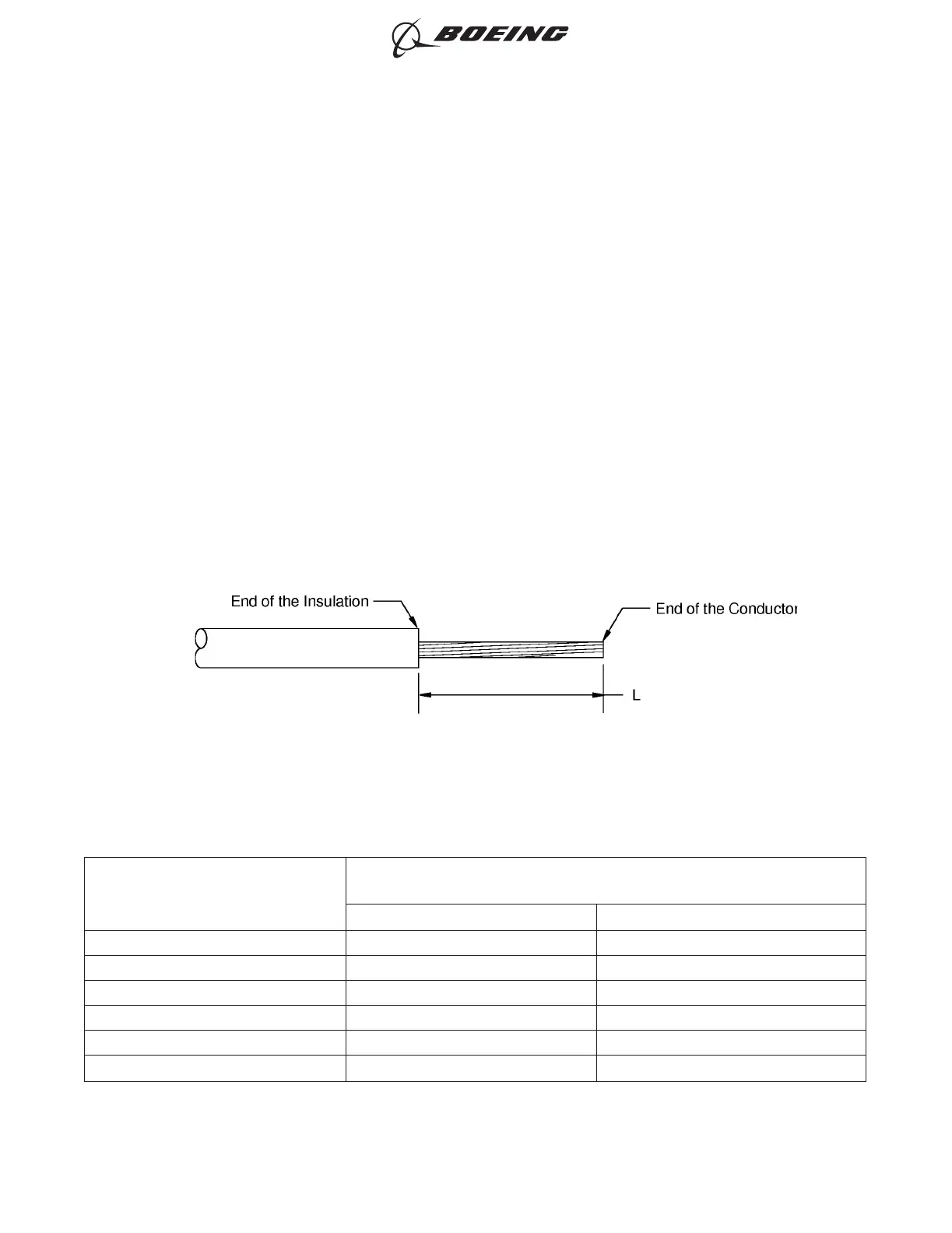

• Figure 40

• Table 67 for the insulation removal length

• Subject 20-00-15 for the insulation removal procedures.

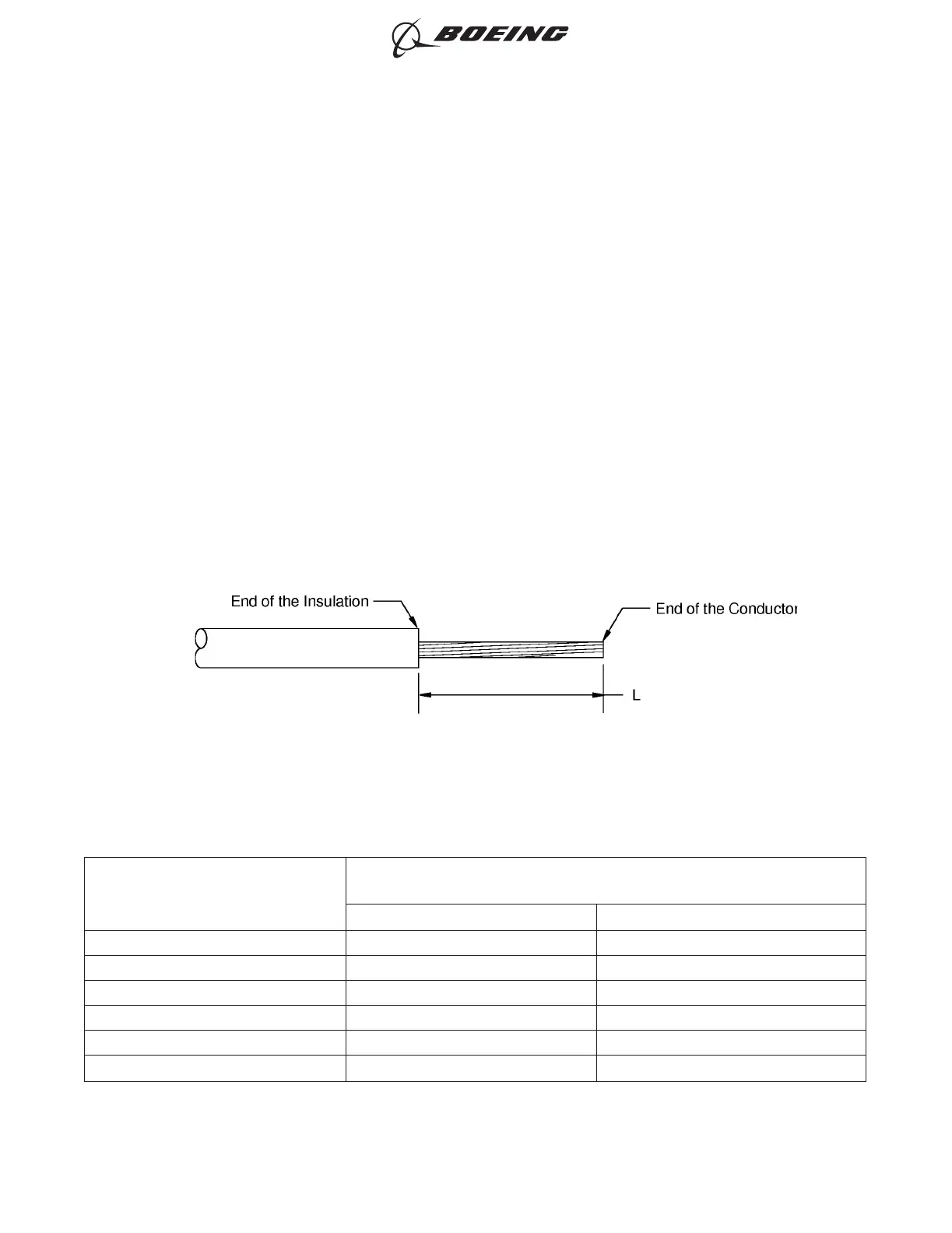

Table 67

INSULATION REMOVAL LENGTH

Splice Part Number

Insulation Removal Length L

(inch)

Target Tolerance

BACT12C101 0.72 ±0.03

BACT12C12 0.34 ±0.03

BACT12C21 0.65 ±0.03

BACT12C4 0.53 ±0.03

BACT12C4NK 0.47 ±0.03

BACT12C6 0.53 ±0.03

INSULATION REMOVAL LENGTH

Figure 40

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 81

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...