CAUTION

DO NOT APPLY PRESSURE OR STRONG FORCE ON THE TONGUE

OF THE TERMINAL LUG AT THE HOLES IN THE TONGUE. DAMAGE

TO THE TERMINAL LUG CAN OCCUR.

(10) Examine the terminal lug assembly.

Make sure that:

• The terminal lug has no cracks

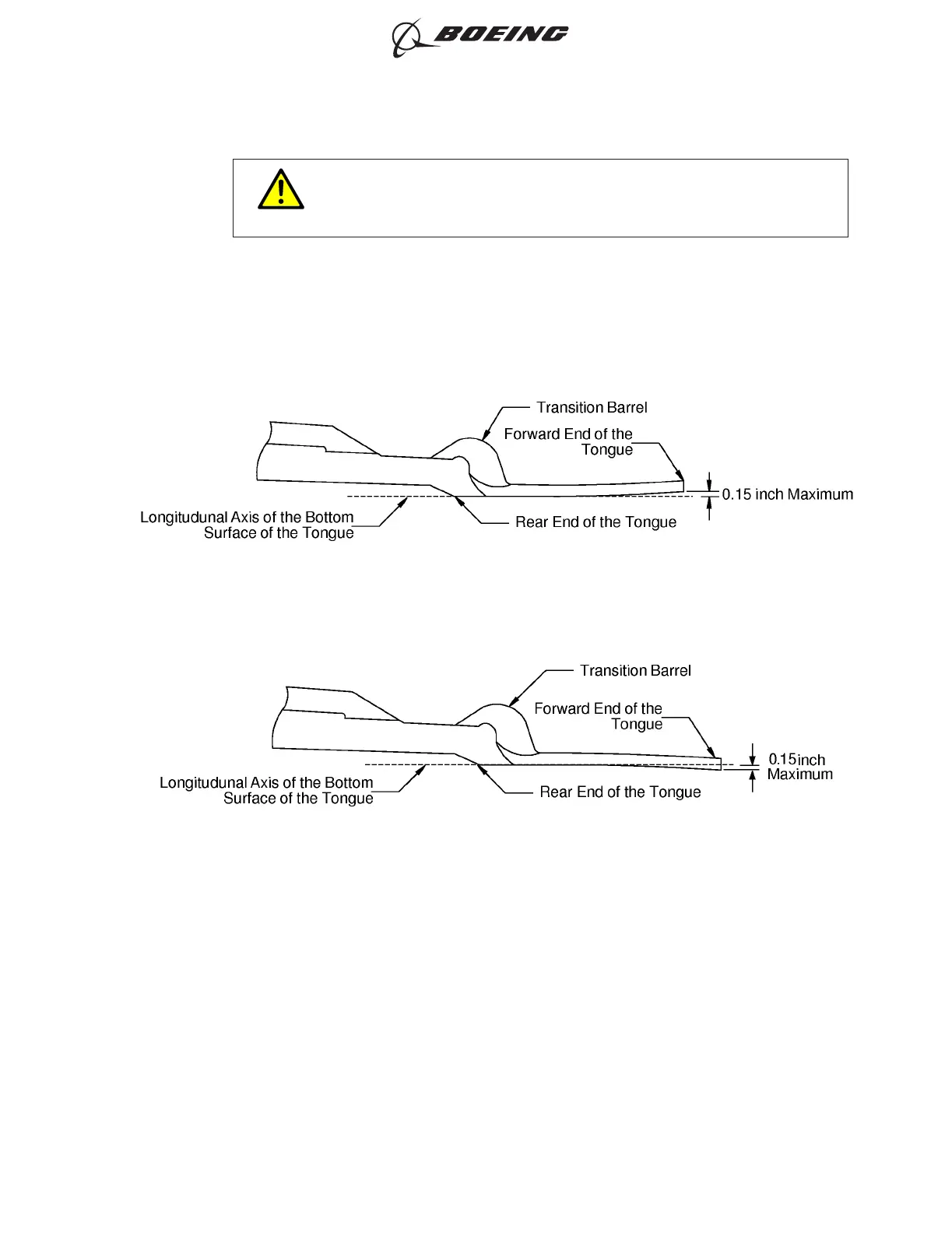

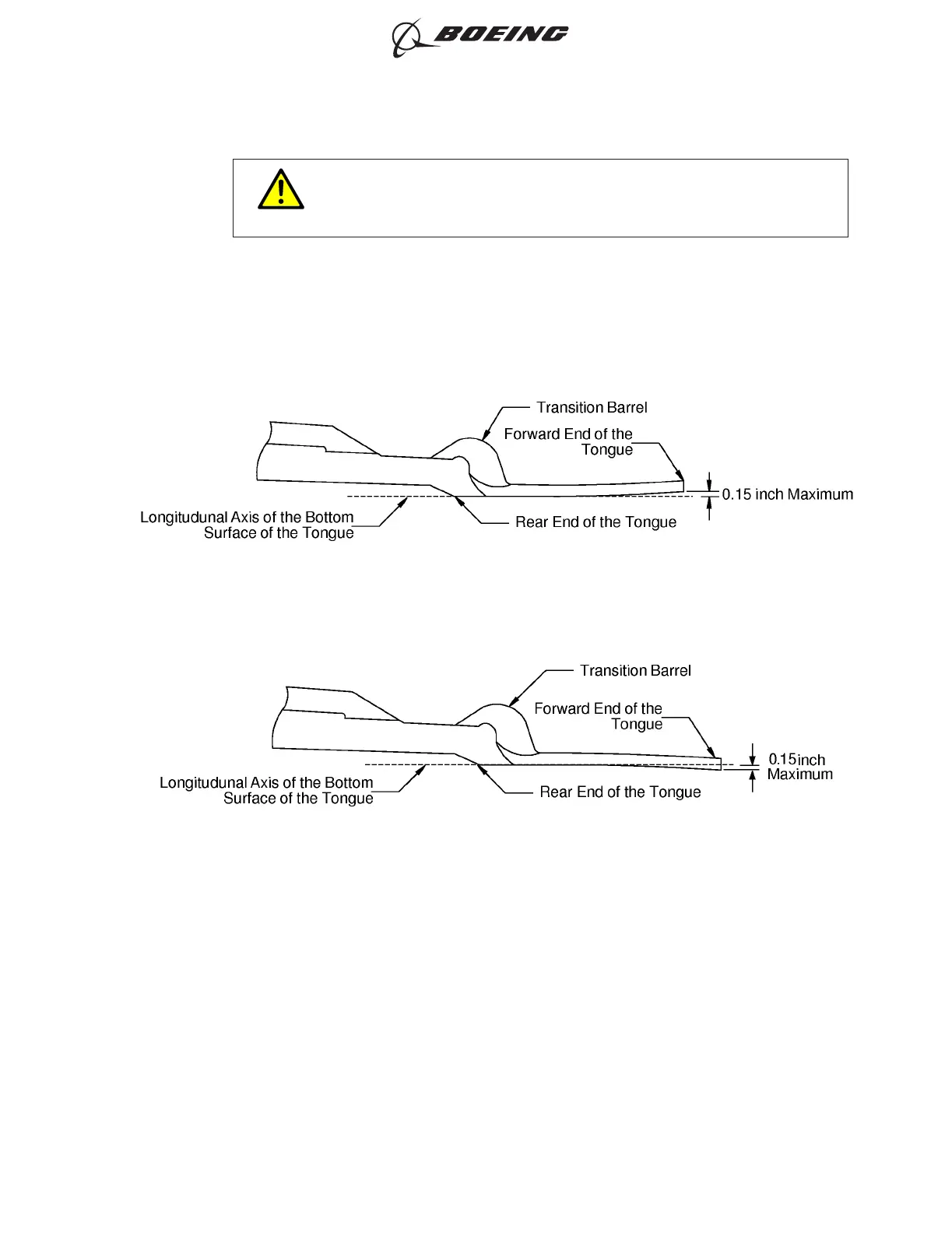

• The tongue of the terminal lug does not have a bend that is more than 0.15 inch from the

longitudinal axis of the bottom surface of the tongue. Refer to Figure 18 and Figure 19.

• The forward edge of the crimp mark is not farther than 0.13 inch from the rear end of the

tongue of the terminal lug. Refer to Figure 20.

• The certification mark is in the center of the bottom of the crimp impression; refer to Figure

21.

• The mark is formed correctly; refer to Figure 21.

• The angle of the crimped end is less than 15 degrees from the longitudinal axis of the

terminal lug. Refer to Figure 22.

TERMINAL LUG TONGUE-BENT UP

Figure 18

TERMINAL LUG TONGUE-BENT DOWN

Figure 19

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 30

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...