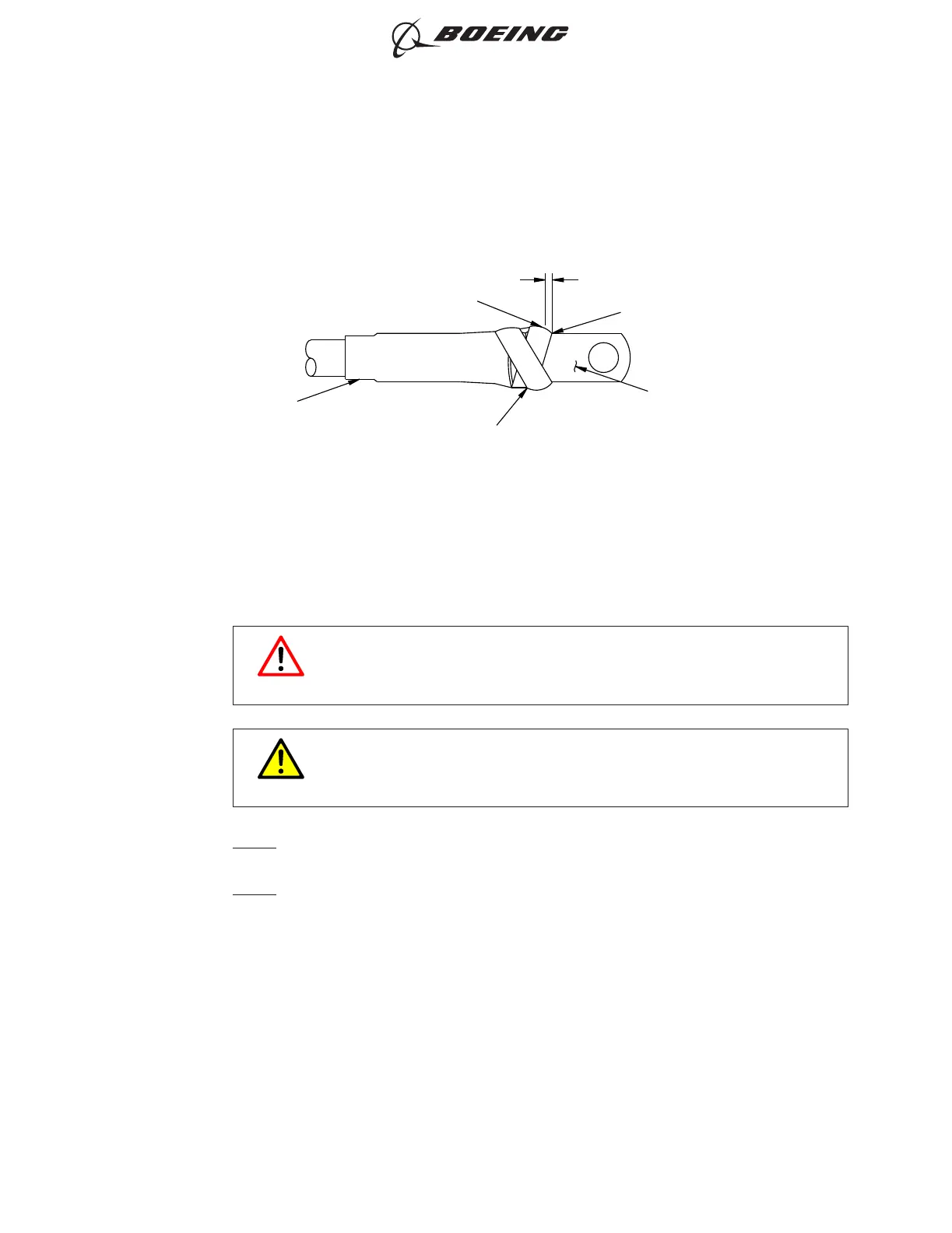

(c) Examine the extension of the terminal lug insulation. Refer to Figure 15.

Make sure that:

1) The tape makes an overlap with the notch of the tongue of the terminal lug.

2) The tape does not extend farther than 0.025 inch forward from the edge of the notch.

(8) Crimp Tool Preparation

This Subject gives the procedures for preparation of the Hydraulic Crimp Tool.

(a) Preparation of the 58422-1 Hydraulic Crimp Tool

Refer to Figure 16, Figure 17 and Figure 18.

WARNING

DO NOT ACCIDENTLY PRESS THE FOOT PEDAL OR THE HANDLE

CONTROL WHILE THE DIES ARE REMOVED OR INSTALLED. INJURY

TO PERSONNEL CAN OCCUR.

CAUTION

DO NOT INSTALL DIFFERENT DIES FROM DIFFERENT DIE SETS IN A

CRIMP TOOL HEAD. DAMAGE TO THE EQUIPMENT CAN OCCUR.

NOTE: The standard configuration of the crimp tool dies is the nest as the stationary die

and the indenter as the moving die.

NOTE: As an alternative to make the crimp operation easier, the indenter can be used as

the stationary die and the nest can be used as the moving die.

0.025 INCH MAXIMUM

BOTTOM SURFACE OF

THE TONGUE

FORWARD EDGE OF THE TAPE

0.5 INCH SILICONE TAPE

INSULATION SLEEVE

EDGE OF NOTCH

2528890 S0000597241_V1

Position of the Tape on the Bottom Surface of the Tongue

Figure 15

ASSEMBLY OF BACT12BC TE ALUMINUM TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-08

Page 13

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...