This rotates the threader motor worm gear (6 in Figure 8-136 on page 8-126)

clockwise, drawing the tape leader block assembly (LBA) into the cartridge.

4. As the LBA is secured in the cartridge, you should hear the LBA retention

spring clips click into place. If you do not hear the click, continue rolling until

the threader motor worm gear (4 in Figure 8-136 on page 8-126) stops. The

LBA is in the correct position.

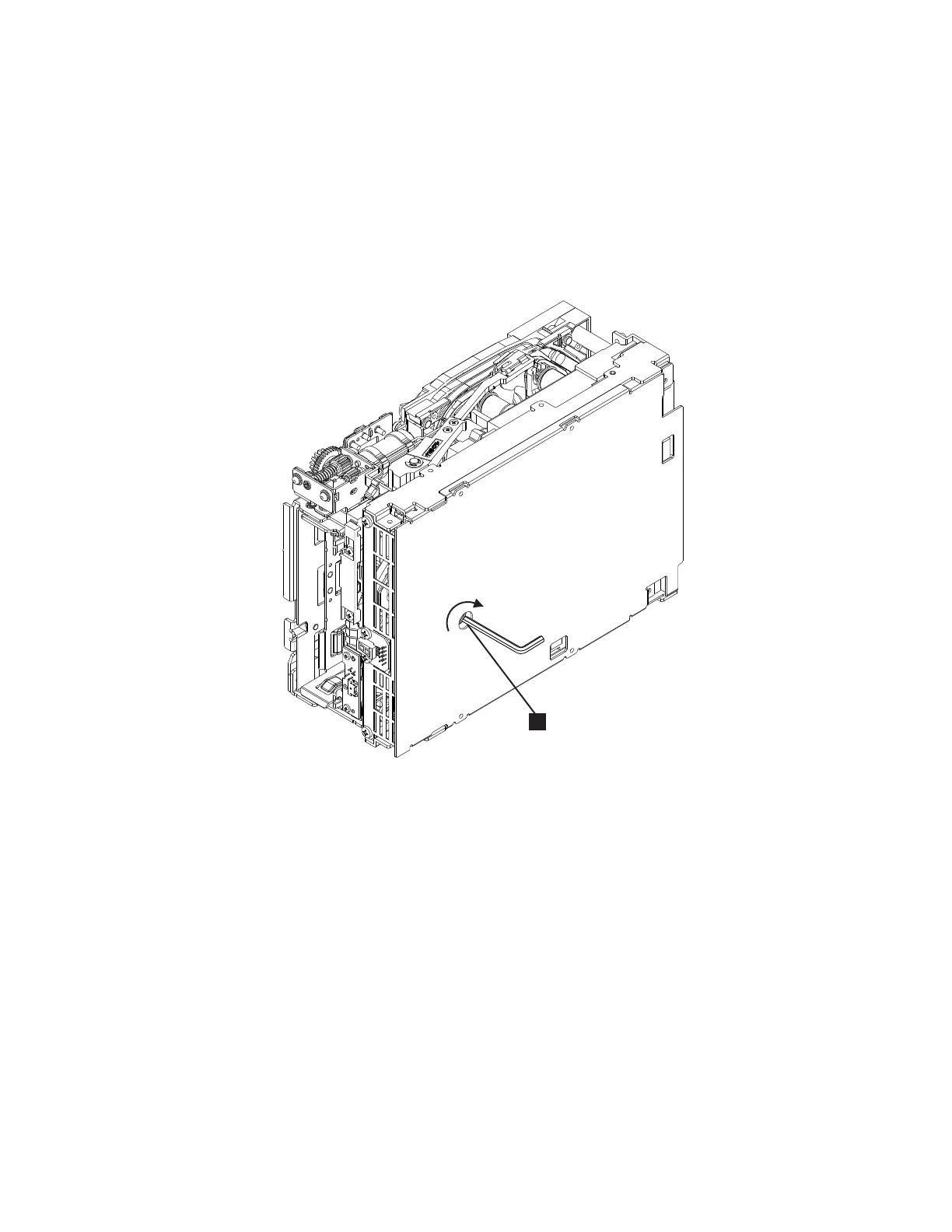

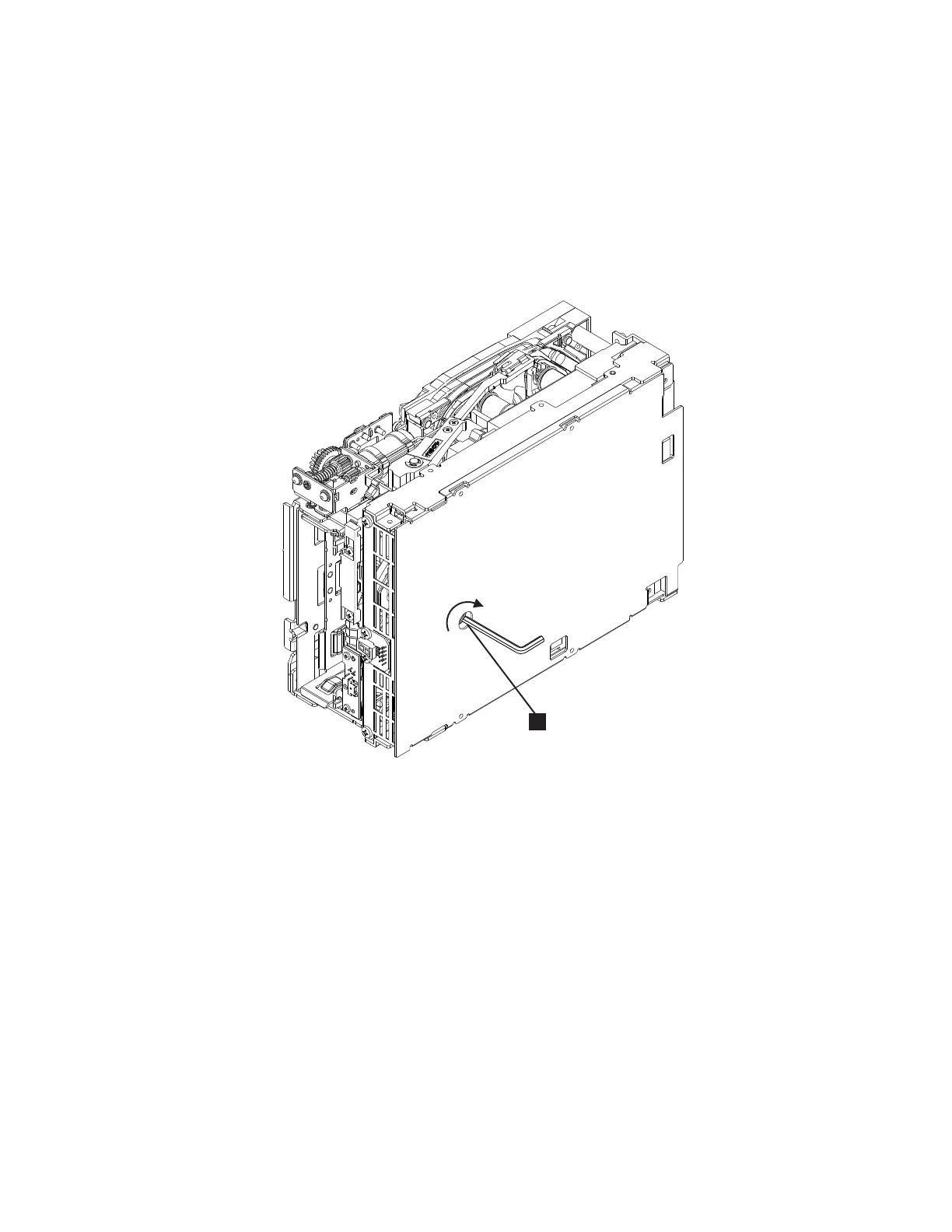

Note: Be sure to keep tension on the tape as the LBA is drawn into the

cartridge by using a hex wrench (1) in Figure 8-137.

5. Notice the following:

a. Loader mechanism gear (8 in Figure 8-136 on page 8-126) nearest the

front of the drive that actuates the cartridge loader mechanism

b. Position of the rotator stub (3 in Figure 8-136 on page 8-126).

c. Front loader motor worm gear (8 in Figure 8-136 on page 8-126).

Rotating this gear allows the loader mechanism gear (1 in Figure 8-136

on page 8-126) to turn.

6. Rotate the loader motor worm gear (1 in Figure 8-136 on page 8-126) to turn

the loader mechanism gear (6 in Figure 8-136 on page 8-126)

counterclockwise. Continue turning until the rotator stub (3 in Figure 8-136

on page 8-126) loses contact with the lever (7 in Figure 8-136 on page 8-126).

This releases the LBA leader pin.

7. Rotate the threader motor worm gear (4 in Figure 8-136 on page 8-126) to

turn the threader mechanism gear (6 in Figure 8-136 on page 8-126)

counterclockwise. This moves the LBA out of the cartridge and past the

read/write head. Stop this rotation when the LBA is near the tape guide roller

a82ru008

1

Figure 8-137. Using hex wrench to rewind tape into cartridge

Chapter 8. Add, Check, Adjust, Remove, and Replace Procedures 8-127

Loading...

Loading...