(10) Remove dial indicator and install spark plug.

(11) Remove camshaft alignment Special Tools

6642 and install cam covers and O-rings. Tighten fas-

teners to 28 N·m (250 in. lbs.).

(12) Install timing belt covers. Refer to Timing

Belt Covers in this section.

(13) Install crankshaft damper.

(14) Install accessory drive belts. Refer to COOL-

ING SYSTEM for procedure.

(15) Fill cooling system. Refer to COOLING SYS-

TEM for procedure.

(16) Start engine and allow to idle for approxi-

mately 1 minute. If a noticeable noise is present from

the timing belt/tensioner, air has possibly entered the

tensioner.

(a) To remove air from tensioner; using a DRB

IIIt, operate the engine at speed of 1600–2000

RPM for 10 minutes. This will purge air from ten-

sioner and noise will be dissipated.

NOTE: If air is present, the tensioner will be soft

and may generate noise. This noise should disap-

pear after no more than 15 minutes of engine run-

ning time.

ROCKER ARMS AND SHAFT ASSEMBLY

CAUTION: The rocker arm shafts are hollow and

are used as lubrication oil passages. The rocker

arm and shaft assembly on the RIGHT side of the

engine has an oil passage hole from the cylinder

head to the third rocker shaft support. The rocker

arm shaft assembly on the LEFT side of the engine

has an oil passage hole from the cylinder head to

the second rocker shaft support.

REMOVAL

(1) Remove cylinder head covers. Refer to proce-

dure in this section.

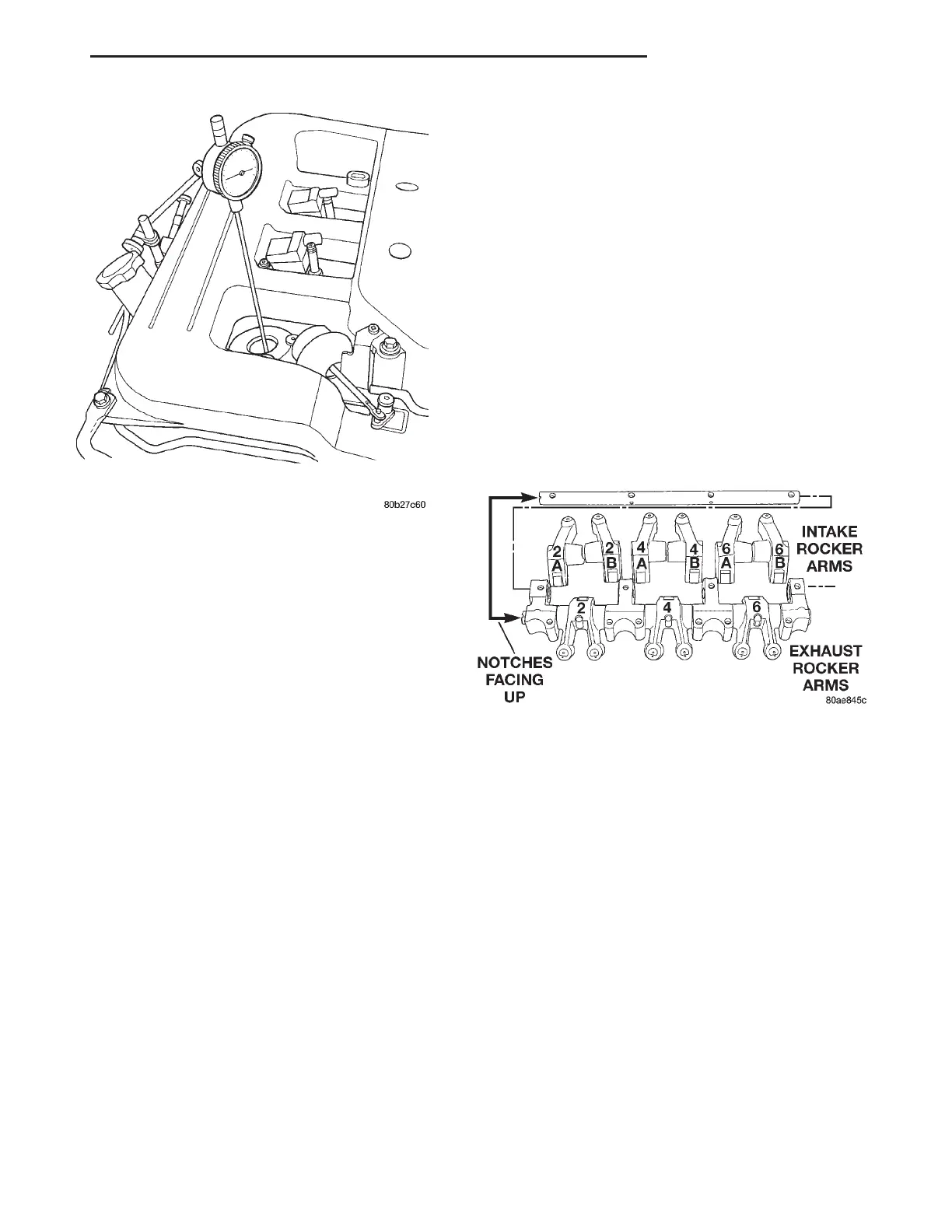

(2) Identify the rocker arm assembly and rocker

arms before disassembly (Fig. 80).

(3) Remove rocker arm assembly bolts.

(4) Remove rocker arm assembly.

NOTE: To prevent air ingestion into lash adjusters,

avoid turning rocker arm assembly upside down.

CAUTION: Do not allow rocker arm assembly to

rest on lash adjusters, as damage may occur to

lash adjusters and/or plastic retainers.

DISASSEMBLY

(1) Remove dowel pin usinga4mmscrew, nut,

spacer, and washer installed into the pin (Fig. 81).

Tighten the screw into the pin, then loosen the nut

on the screw. This will pull the dowel out of the shaft

support. Do not reuse dowel pins. Remove the rocker

arms and pedestals in order.

(2) Check the rocker arm mounting portion of the

shafts for wear or damage. Replace if damaged or

heavily worn.

(3) Check shaft oil holes for clogging with small

wire, clean as required.

ASSEMBLY

CAUTION: New dowel pins must be installed during

assembly.

(1) Install the rocker arms, and pedestals onto the

shaft.

Fig. 79 Dial Indicator Locating Piston at TDC

Fig. 80 Rocker Arms and Shaft Identification—Left

Bank

LH 3.2/3.5L ENGINE 9 - 119

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...