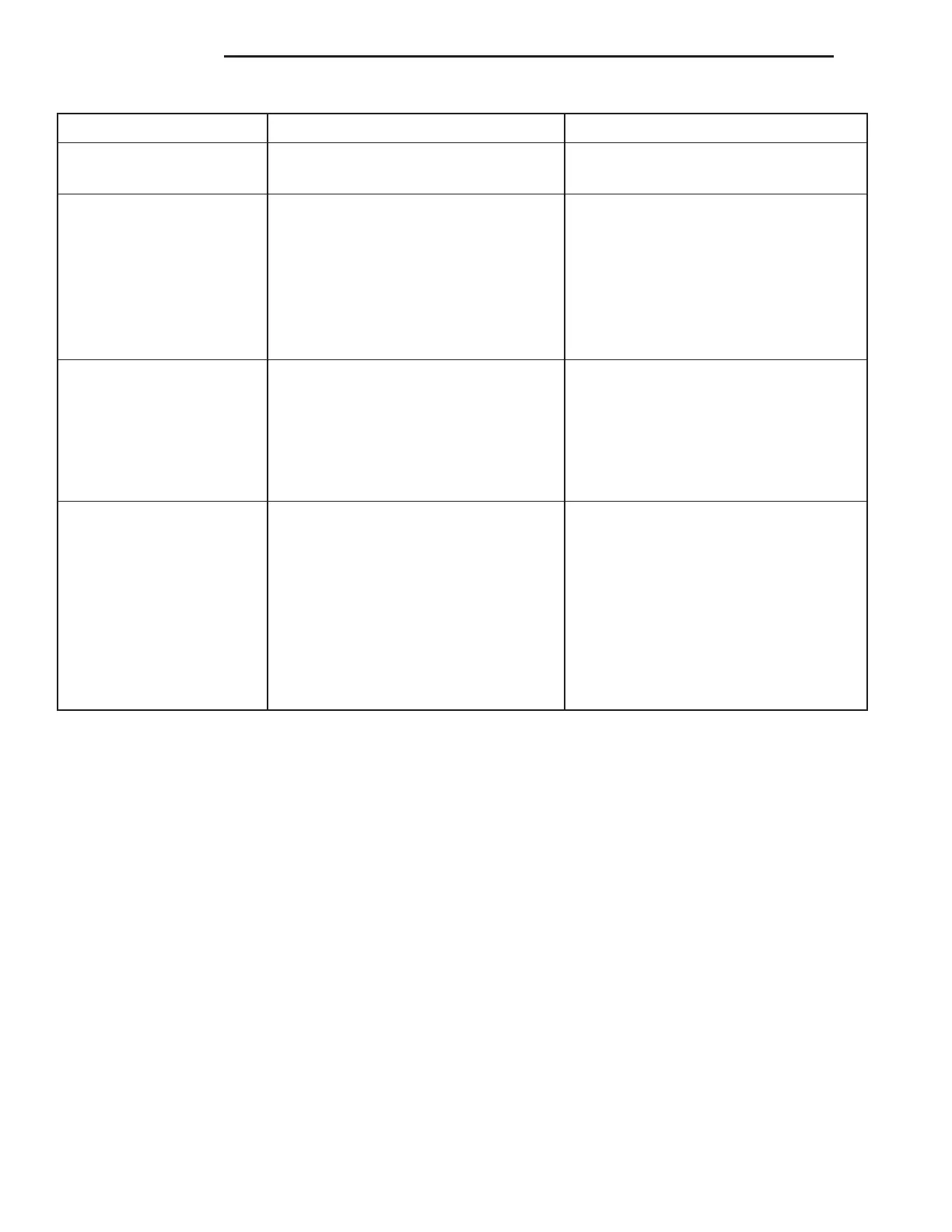

CONDITION POSSIBLE CAUSES CORRECTION

7. Excessive friction in strut upper

bearing

7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free

Play

1. Worn or loose tie rod ends 1. Replace or tighten tie rod ends

2. Loose steering gear mounting bolts 2. Tighten steering gear bolts to specified

torque

3. Worn steering gear 3. Replace Steering Gear

4. Loose or worn steering shaft coupler 4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Low power steering fluid level 2. Fill power steering fluid reservoir to

correct level

3. Loose power steering pump drive

belt

3. Correctly adjust power steering pump

drive belt

4. Lack of lubricant in ball joints 4. Lubricate or replace ball joints

5. Steering gear malfunction 5. Replace steering gear

6. Lack of lubricant in steering coupler 6. Replace steering coupler

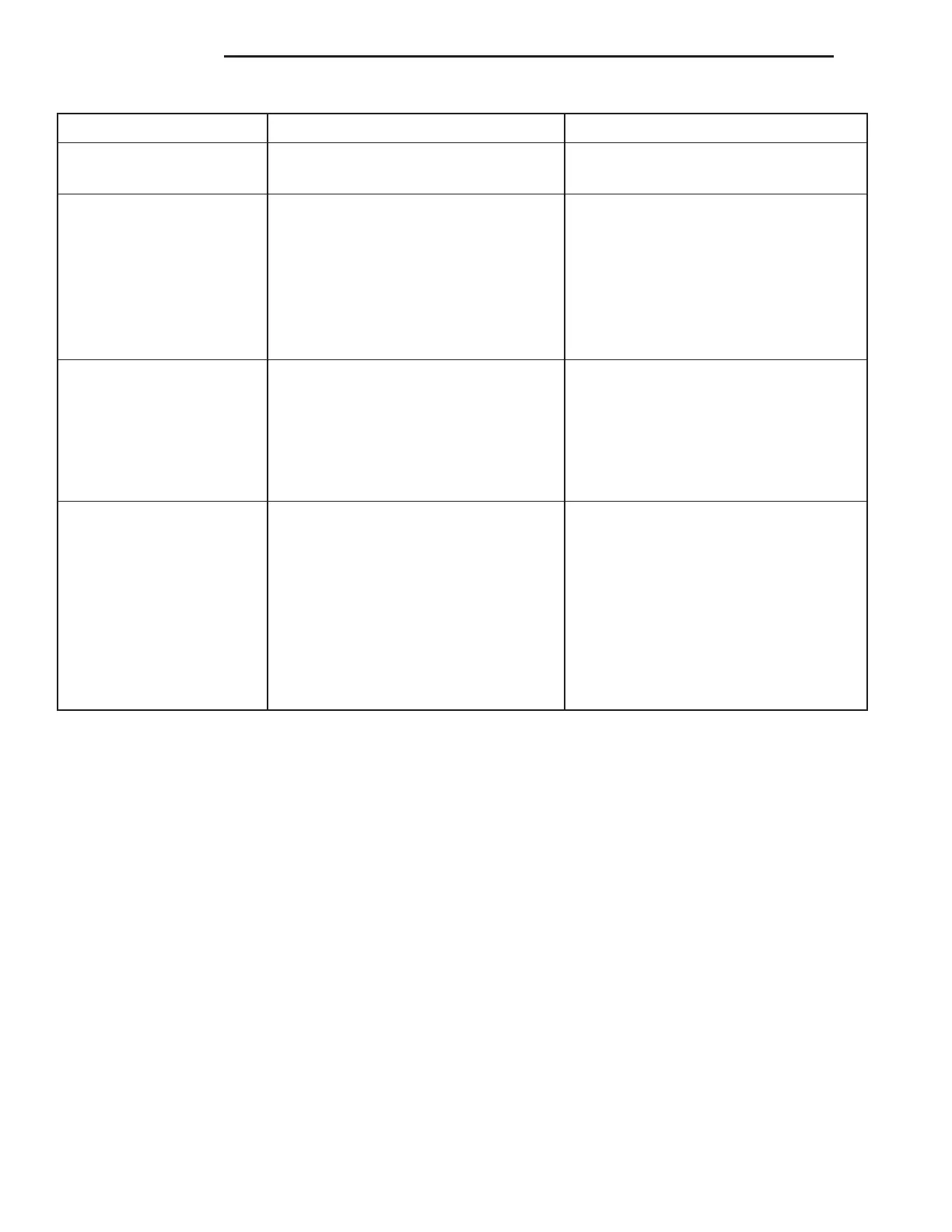

VEHICLE LEAD DIAGNOSIS AND CORRECTION

Use the following chart to diagnose a vehicle that

has a complaint of a drift or lead condition. The use

of the chart will help to determine if the lead condi-

tion is the result of a bad tire or is caused by the

front wheel alignment.

SERVICE PROCEDURES

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment factors. The following part

inspection and the necessary corrections should be

made to those parts which influence the steering of

the vehicle.

(1) Check and inflate all tires to recommended

pressure. All tires should be the same size and in

good condition and have approximately the same

wear. Note the type of tread wear which will aid in

diagnosing, see Wheels and Tires, Group 22.

(2) Check front wheel and tire assembly for radial

runout.

(3) Inspect lower ball joints and all steering link-

age for looseness.

(4) Check for broken or sagged front and rear

springs.

(5) Check vehicle ride height to verify it is within

specifications.

(6) Alignment MUST only be checked after the

vehicle has the following areas inspected and or

adjusted. Recommended tire pressures, full tank of

fuel, no passenger or luggage compartment load and

is on a level floor or a properly calibrated alignment

rack.

CURB HEIGHT MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

2 - 4 SUSPENSION LH

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...