listed below. Be sure to place the tubing nut on

tube before proceeding to flare the tubing.

(1) Carefully prepare the end of the tubing to be

flared. Be sure the end of the tubing is square and

all burrs on the inside of the tubing are removed

(Fig. 33). This preparation is essential to obtain

the correct form of a (metric) ISO tubing flare.

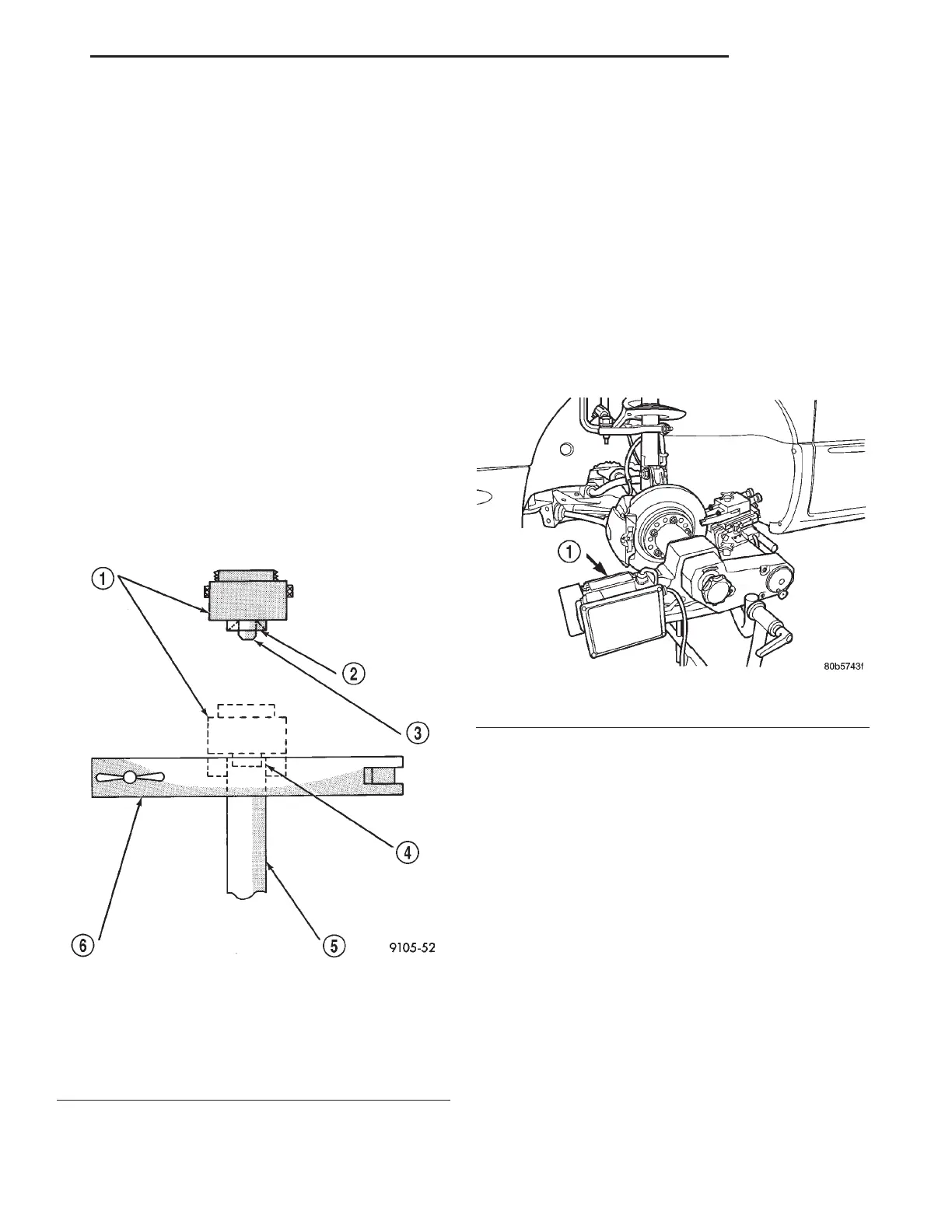

(2) Open the jaws of the Flaring Tool. Align the

jaws of the flaring tool around the tubing. Close the

jaws of the Flaring Tool around the tubing, but do

not lock the tubing in place.

(3) Position tubing in jaws of the Flaring Tool so

that it is flush with top surface of flaring tool bar

assembly (Fig. 34).

(4) Install the correct size adaptor for the brake

tubing being flared, on the feed screw of the yoke

assembly. Center the yoke and adapter over the end

of the tubing. Apply lubricant to the adapter area

that contacts the brake tubing. Make sure the

adapter pilot is fully inserted in the end of the brake

tubing. Tighten screw on yoke assembly until the

adaptor has seated squarely on the surface of the bar

assembly (Fig. 34). This process will properly create

a metric ISO tubing flare.

BRAKE ROTOR MACHINING

BRAKE ROTOR MACHINING

NOTE: Refacing of the rotor is not required each

time the brake pads are replaced.

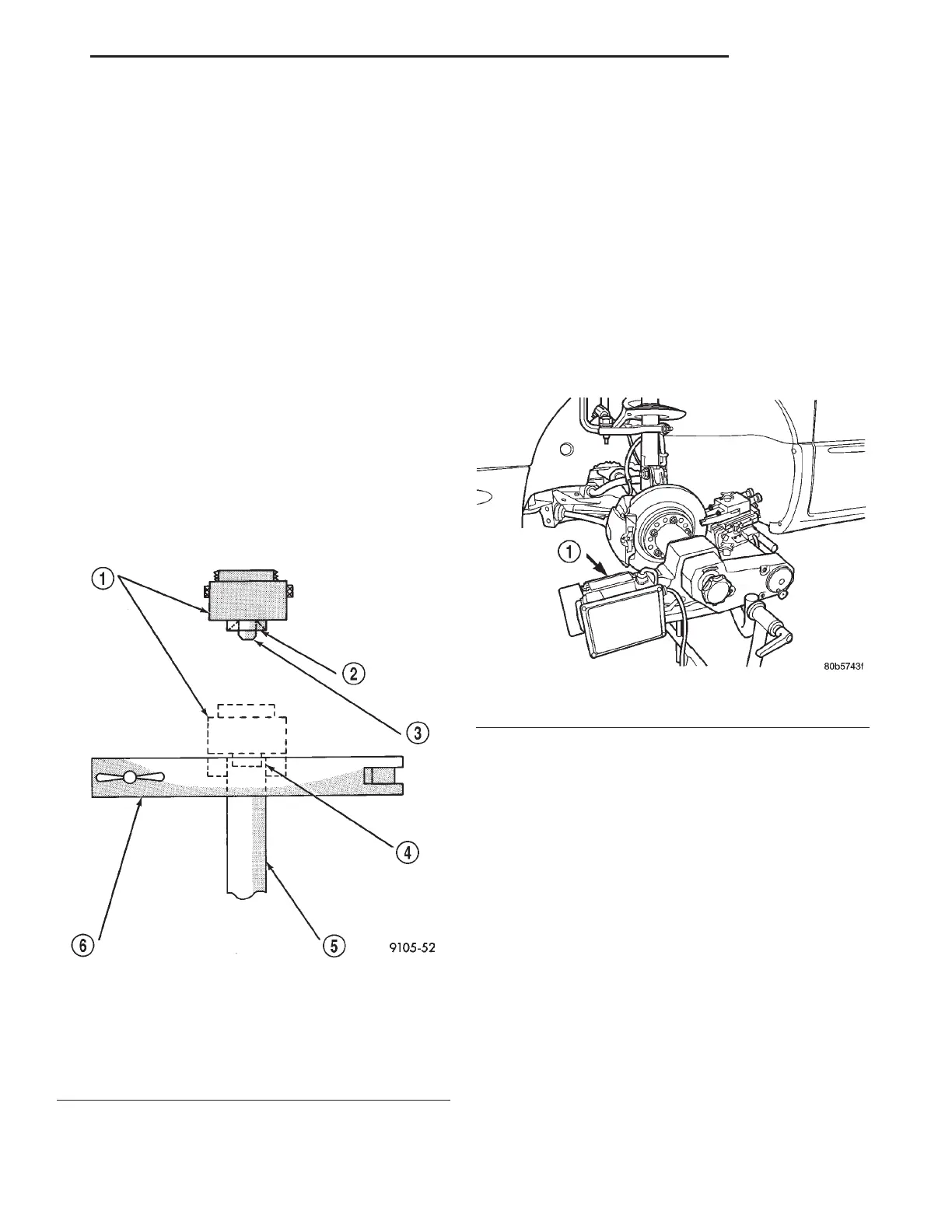

Any servicing of the rotor requires extreme care to

maintain the rotor within service tolerances to

ensure proper brake action.

If the rotor surface is deeply scored or warped, or

there is a complaint of brake roughness or brake

pedal pulsation, the rotor should be refaced using a

hub-mounted on-car brake lathe (Fig. 35), or

replaced.

The use of a hub-mounted on-car brake lathe is

highly recommended to eliminate the possibility of

excessive runout. It trues the brake rotor to the vehi-

cle’s hub and bearing.

NOTE: All rotors have markings for minimum allow-

able thickness cast on an un-machined surface of

the rotor (Fig. 36) or (Fig. 37).

Minimum allowable thickness is the minimum

thickness which the brake rotor machined surface

may be cut to.

CAUTION: Do not machine the rotor if it will cause

the rotor to fall below minimum thickness.

Before installation, verify the brake rotor face and

the hub adapters are free of any chips, rust, or con-

tamination.

Fig. 34 ISO Tubing Flare Tool

1 – ADAPTER

2 – LUBRICATE HERE

3 – PILOT

4 – FLUSH WITH BAR

5 – TUBING

6 – BAR ASSEMBLY

Fig. 35 Refacing Brake Rotor

1 – ON-CAR BRAKE LATHE

LH BRAKES 5 - 23

SERVICE PROCEDURES (Continued)

Loading...

Loading...