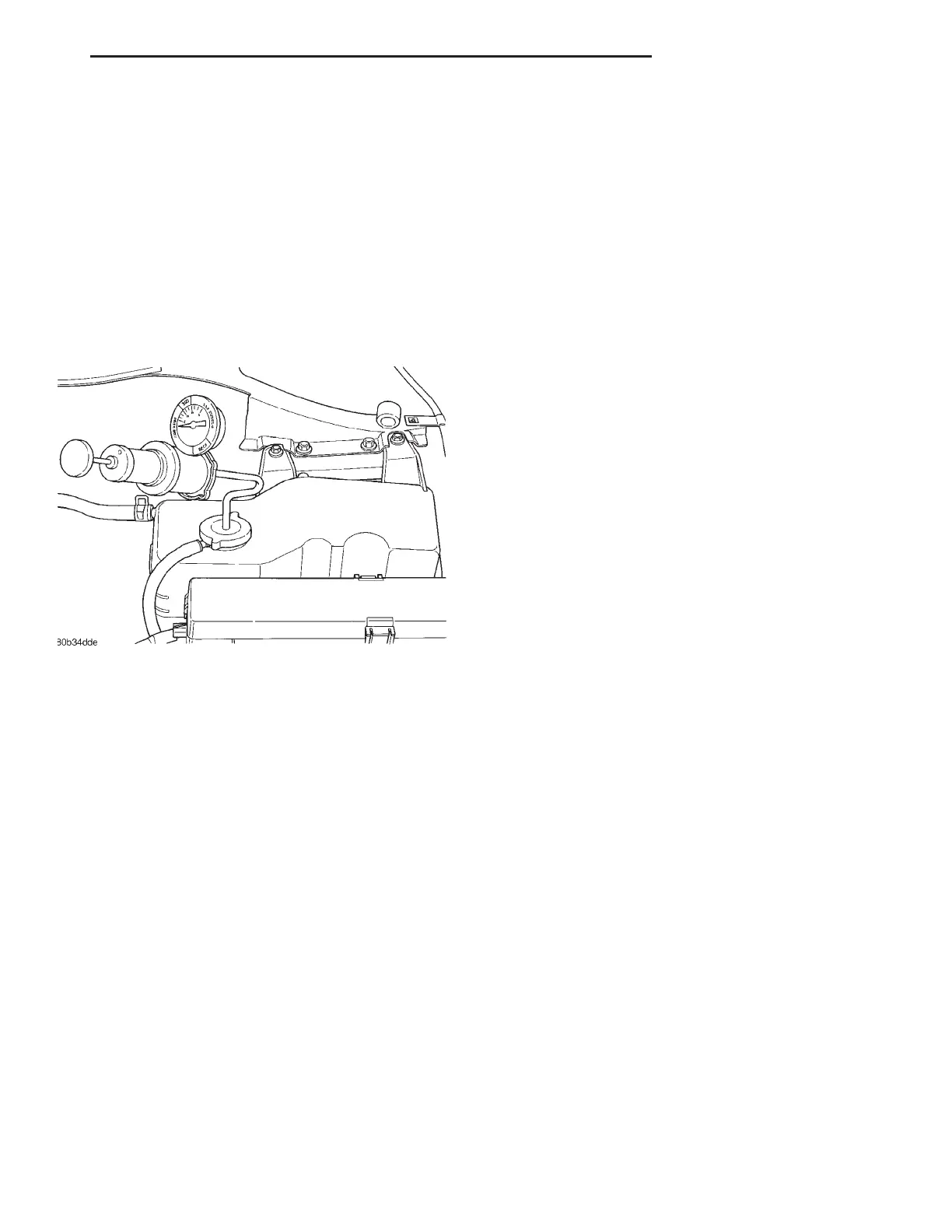

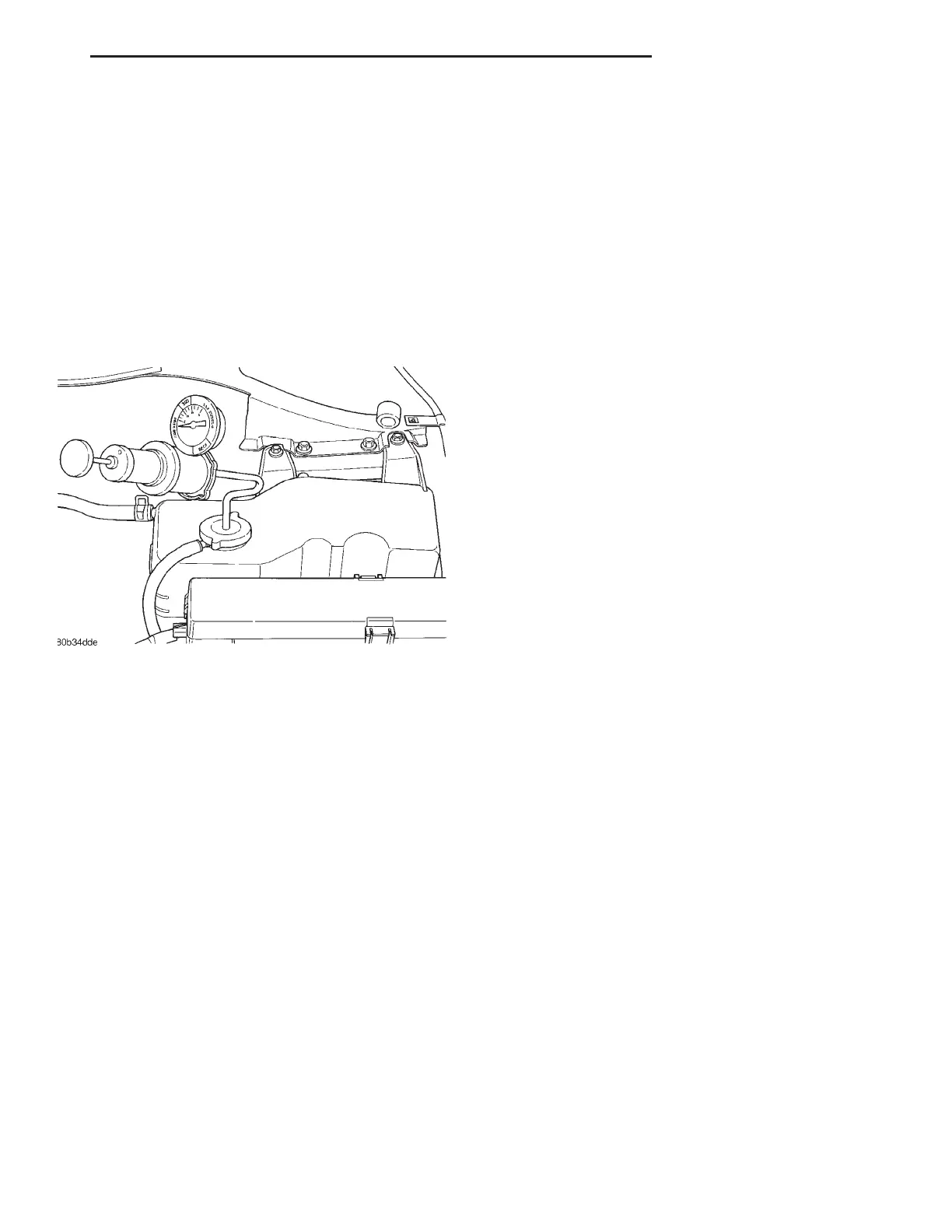

TESTING SYSTEM FOR LEAKS

With engine not running, wipe the coolant bottle

neck sealing seat clean.

Attach a radiator pressure tester to the coolant

bottle, as shown in (Fig. 18) and apply 104 kPa (15

psi) pressure. If the pressure drops more than 2 psi

in 2 minutes inspect all points for external leaks.

All hoses, radiator and heater, should be moved

while at 15 psi since some leaks occur while driving

due to engine rock, etc. If the cooling system will not

pressurize easily and there is no coolant leaks, the

cooling system is only partially filled. Refer to filling

procedure in this section.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start

engine and run the engine to normal operating tem-

perature in order to open the thermostat and allow

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH TOOL IN PLACE PRESSURE

BUILDS UP FAST. ANY EXCESSIVE AMOUNT OF

PRESSURE BUILT UP BY CONTINUOUS ENGINE

OPERATION MUST BE RELEASED TO A SAFE

PRESSURE POINT. NEVER PERMIT PRESSURE TO

EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block or

cylinder head.

There may be internal leaks which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate a

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

LOW COOLANT LEVEL

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

at running and at operating temperature, the high

pressure inlet tank runs full and the low pressure

outlet tank drops. If this level drops below the top of

the transmission oil cooler, air will be drawn into the

water pump:

• Transmission oil will become hotter.

• High reading shown on the temperature gauge.

• Air in the coolant will also cause loss of flow

through the heater core.

• Water pump seal may run dry, increasing the

risk of premature seal failure.

• Exhaust gas leaks into the coolant can also

cause the same problems.

DEAERATION

As air is removed from the cooling system, it gath-

ers in the coolant bottle. This pressure is released

into the atmosphere through the pressure valve

located in the pressure cap when pressure reaches 96

- 124 kPa (14 - 18 psi). This air is replaced with cool-

ant from the coolant bottle.

NOTE: Deaeration does not occur at engine idle—

higher engine speeds are required. Normal driving

will deaerate cooling system.

Fig. 18 Pressure Testing Cooling System

LH COOLING SYSTEM 7 - 17

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...