(2) Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

(3) Before installing the bolts, lubricate the

threads with engine oil.

(4) Install bolts finger tight then alternately

torque each nut to assemble the cap properly.

(5) Tighten the nuts to 27 N·m PLUS 1/4 turn (20

ft. lbs. PLUS 1/4 turn).

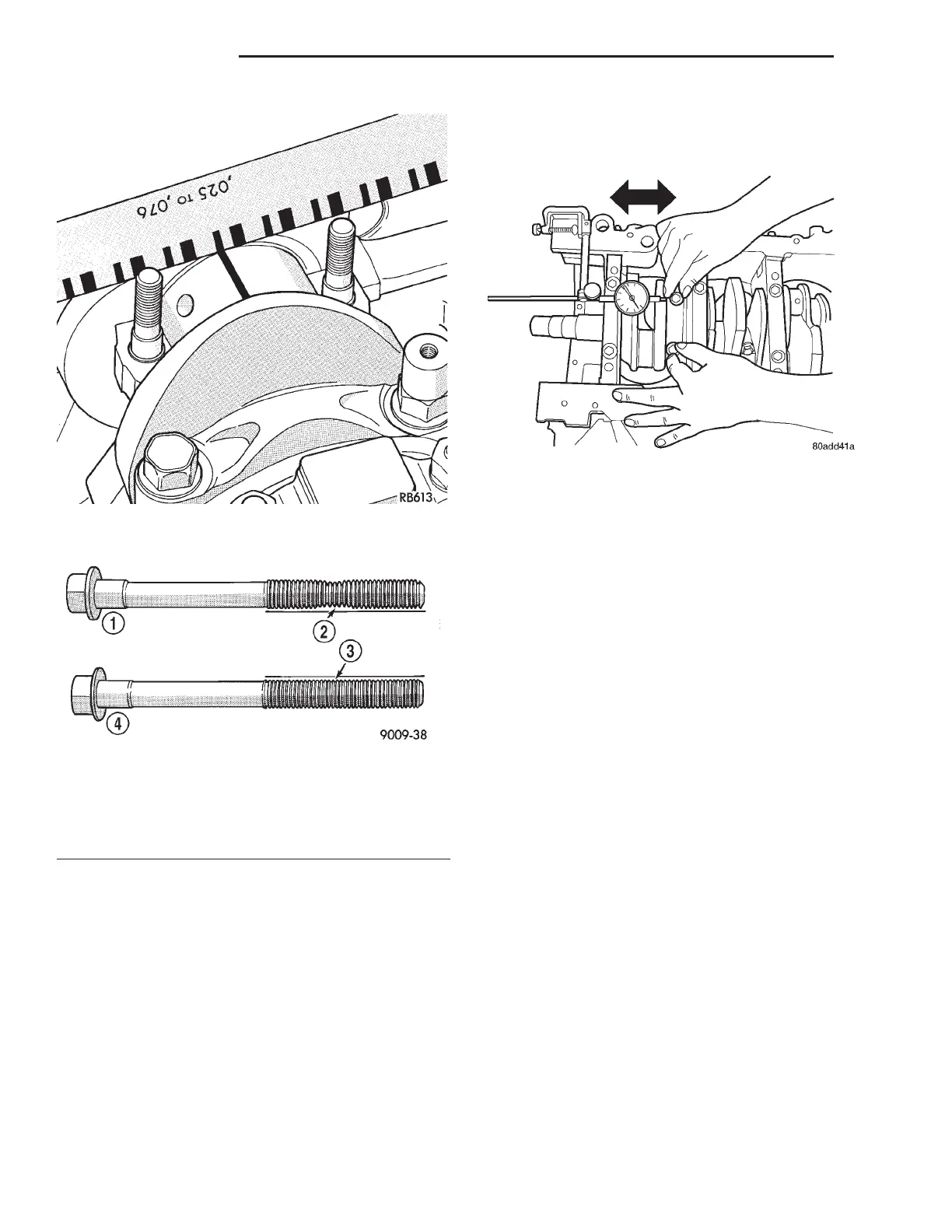

(6) Mount a dial indicator to a stationary point on

engine. Locate probe perpendicular to and resting

against the connecting rod cap being checked. Move

connecting rod all the way to rear of its travel. Zero

the dial indicator. Move connecting rod forward to

limit of travel and read the dial indicator (Fig. 28).

Refer to Engine Specifications. Repeat procedure for

each connecting rod. Turn crankshaft for connecting

rod accessibility.

CRANKSHAFT MAIN BEARING—FITTING

The main bearings are “select fit” to achieve proper

oil clearances. For main bearing selection, the block

and crankshaft have grade identification marks.

The grade marks for the cylinder block main bear-

ing bore grade is located on the pan rail just below

the left side engine mount bracket (Fig. 30). These

marks are read left to right, corresponding to main

bore 1, 2, 3, 4.

The grade marks for the crankshaft are located on

the rearmost crankshaft counter weight as shown in

(Fig. 29). The crankshaft journal grade marks are

read left to right, corresponding with journal number

1, 2, 3, 4.

Use the Main Bearing Selection Chart to properly

select the main bearings. For an example, if the main

bore grade is 3 and the journal grade is 2, the proper

select fit bearing would be (2) +0.003 mm (+0.0002

in.).

NOTE: Service main bearings have a number from

1 – 5 marked in ink on the bearing surface (Fig. 31).

For verification, use the Main Bearing Selection

Chart for number to size identification.

The upper main bearing has a oil feed hole and a

center groove to allow lubrication of the main journal

and must be properly positioned in the block.

NOTE: Although cylinder bores are graded for size,

there is only one piston size.

Fig. 26 Checking Connecting Rod Bearing

Clearance—Typical

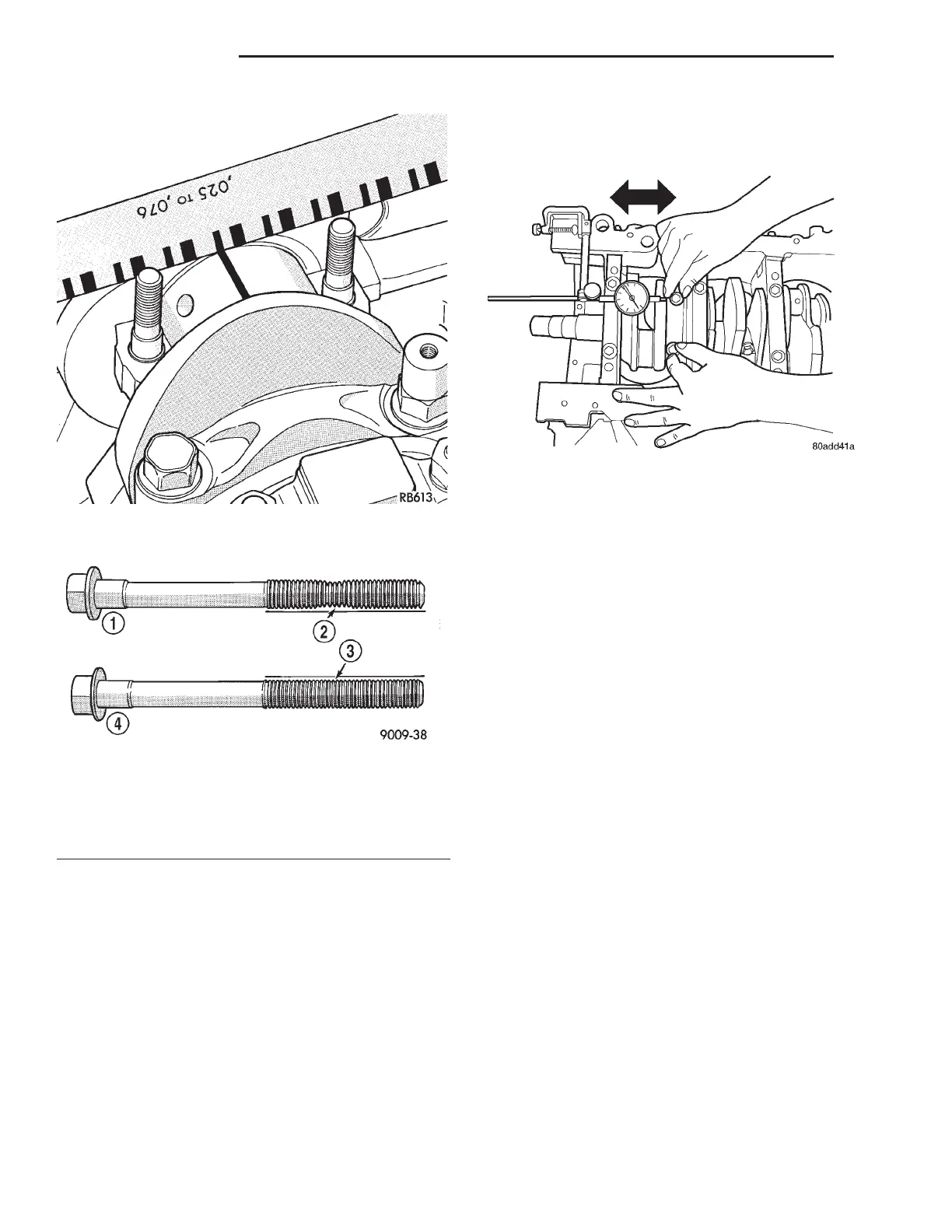

Fig. 27 Check for Stretched Bolts

1 – STRETCHED BOLT

2 – THREADS ARE NOT STRAIGHT ON LINE

3 – THREADS ARE STRAIGHT ON LINE

4 – UNSTRETCHED BOLT

Fig. 28 Connecting Rod Side Clearance Measuring

9 - 26 2.7L ENGINE LH

SERVICE PROCEDURES (Continued)

Loading...

Loading...