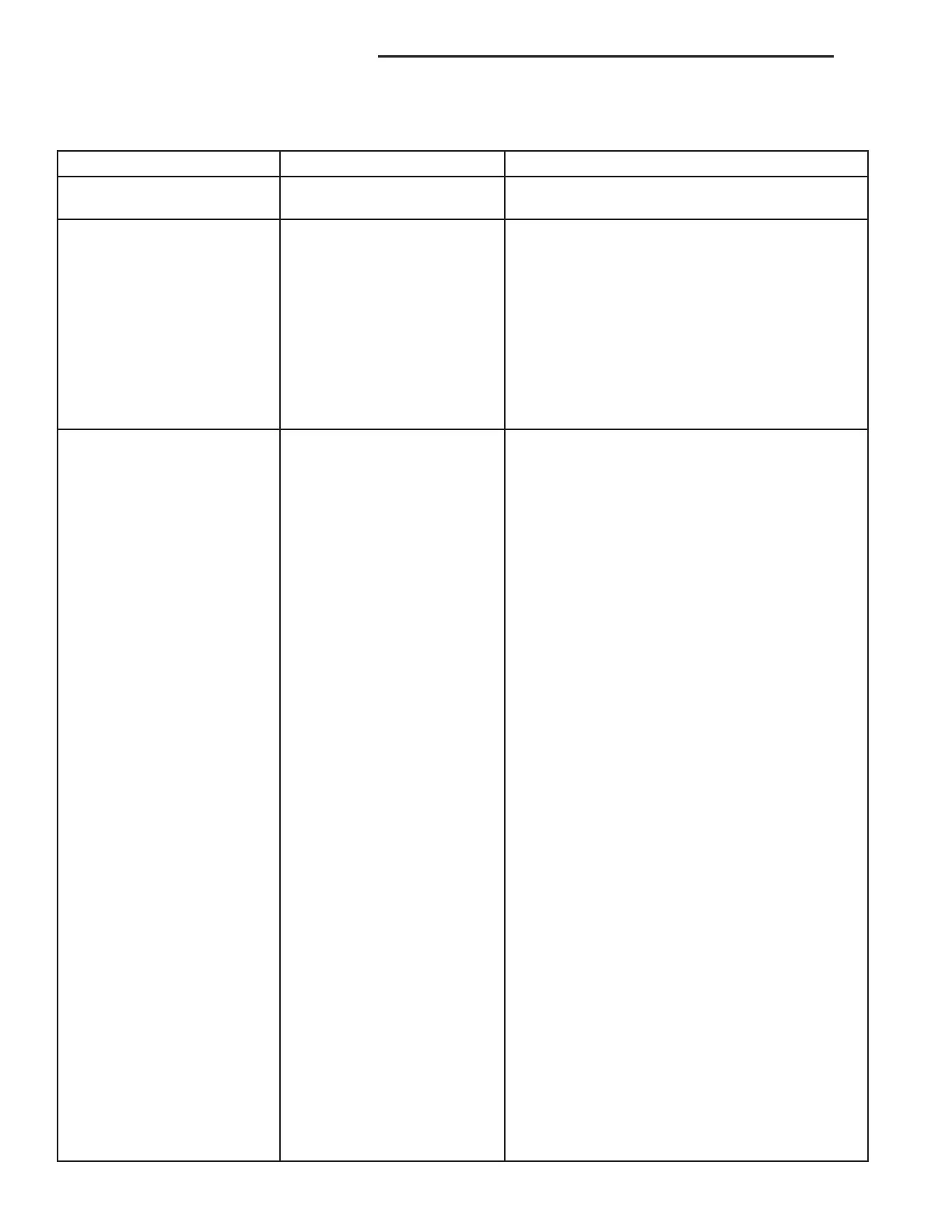

WINDSHIELD WASHER TEST

CONDITION POSSIBLE CAUSE CORRECTION

WASHER POWER FEED

FUSE OPEN

1. JUNCTION BLOCK FUSE

#5 BLOWN.

CHECK FUSE #5. REPLACE IF NOT OK.

BLOWN FUSE WHEN

WASHER SWITCH IS

DEPRESSED

1. SHORT IN WIPER /

WASHER SWITCH.

2. SHORT IN MOTOR

POWER CIRCUIT.

3. SHORT IN WASHER

MOTOR.

1. DEFECTIVE WASHER SWITCH. REFER TO

WIPE / WASHER SWITCH DIAGNOSTIC

PROCEDURES.

2. SHORT OR DEFECTIVE CIRCUIT BETWEEN

WIPER / WASHER SWITCH CONNECTOR

TERMINAL #2 AND MOTOR CONNECTOR

TERMINAL #1. IF NOT OK, REPAIR CIRCUIT.

3. CONNECT AN OHMMETER ACROSS

WASHER MOTOR TERMINALS #1 AND #2 AND

CHECK FOR A SHORT CIRCUIT. IF NOT OK,

REPLACE WASHER MOTOR.

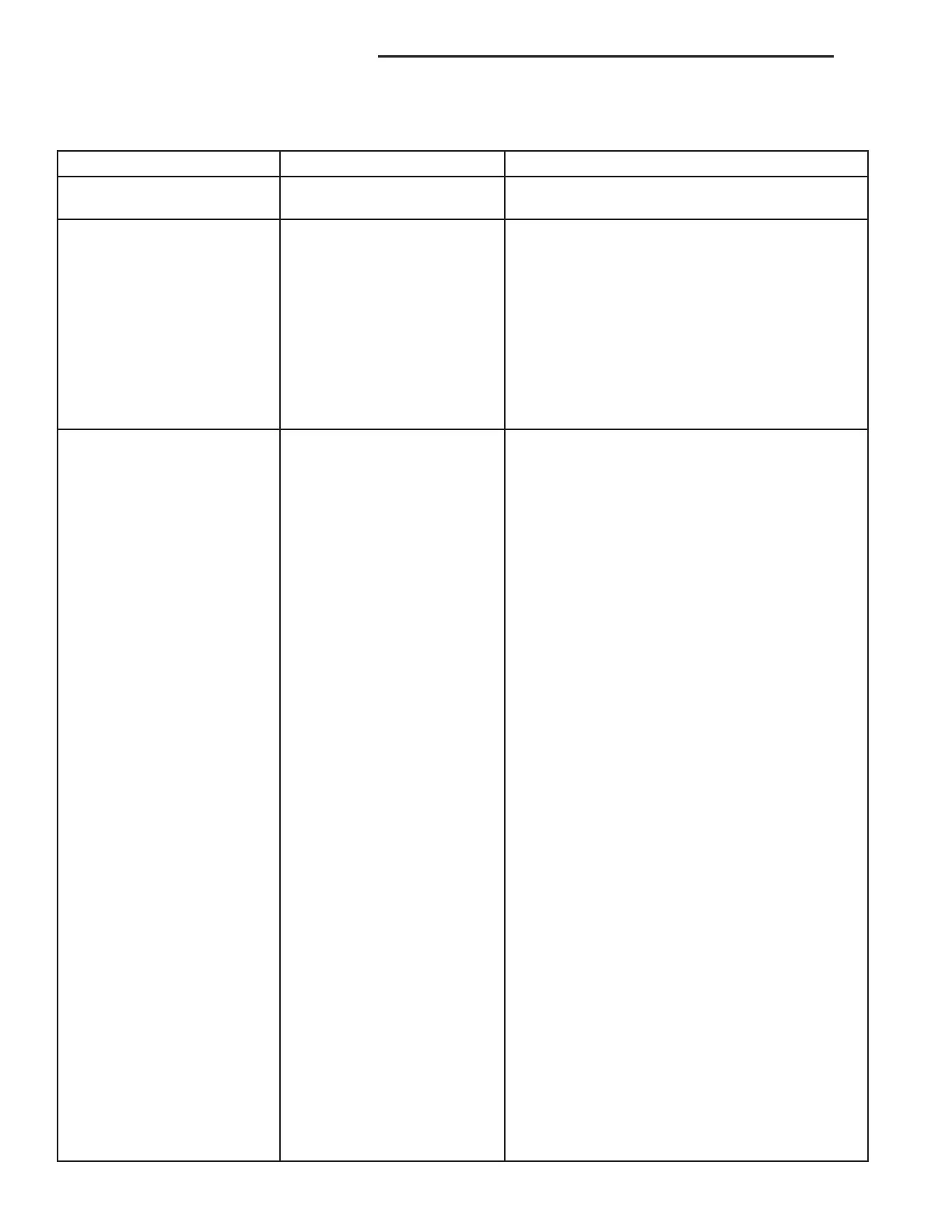

WASHER SYSTEM WILL

NOT FLOW WASHER FLUID

1. NO WASHER FLUID IN

RESERVOIR.

2. JUNCTION BLOCK FUSE

#5 BLOWN.

3. WASHER HOSE NOT

FLOWING FLUID.

4. MOTOR CONNECTOR

LOOSE.

5. MOTOR CONNECTOR

TERMINALS BENT.

6. OPEN POWER CIRCUIT

TO SWITCH.

7. OPEN OR DEFECTIVE

WIPER / WASHER SWITCH.

8. OPEN POWER CIRCUIT

TO MOTOR.

9. OPEN OR DEFECTIVE

MOTOR GROUND CIRCUIT.

10. OPEN CIRCUIT IN

MOTOR.

11. SEIZED MOTOR

BEARINGS.

1. FILL RESERVOIR.

2. SHORT CIRCUIT BETWEEN JUNCTION

BLOCK FUSE #5 AND WIPER SWITCH

TERMINAL #1. SHORT IN WIPER SWITCH. IF

NOT OK, REPAIR CIRCUIT OR REFER TO

WIPER / WASHER SWITCH DIAGNOSTIC

PROCEDURES.

3. ASSURE WASHER HOSE IS NOT PINCHED,

LOOSE, BROKEN, OR DISCONNECTED. IF

NOT OK, PROPERLY ROUTE OR REPAIR

WASHER HOSE.

4. PROPERLY SEAT CONNECTOR TO MOTOR.

5. REPAIR TERMINALS AND PROPERLY SEAT

CONNECTOR TO MOTOR.

6. OPEN OR DEFECTIVE CIRCUIT BETWEEN

JUNCTION BLOCK FUSE #5 AND WASHER

SWITCH CONNECTOR TERMINAL #1. IF NOT

OK, REPAIR CIRCUIT.

7. CONNECT AN OHMMETER ACROSS WIPER

/ WASHER SWITCH TERMINAL #1 AND #2 AND

DEPRESS WASHER BUTTON AND CHECK

FOR CONTINUITY. IF NOT OK, REFER TO

WIPER / WASHER SWITCH DIAGNOSTIC

PROCEDURES.

8. OPEN OR DEFECTIVE CIRCUIT BETWEEN

WIPER / WASHER SWITCH CONNECTOR

TERMINAL #2 AND MOTOR CONNECTOR

TERMINAL #1. IF NOT OK, REPAIR CIRCUIT.

9. OPEN OR DEFECTIVE CIRCUIT BETWEEN

WASHER MOTOR CONNECTOR GROUND

TERMINAL #2 AND LEFT HEADLAMP GROUND

#5 OR ENGINE GROUND #1 OR 2.

10. CHECK FOR AN OPEN CIRCUIT ON

MOTOR BETWEEN POWER TERMINAL #1 AND

GROUND TERMINAL #2. IF NOT OK, REPLACE

WASHER MOTOR.

11. APPLY DIRECT BATTERY VOLTAGE TO

MOTOR TERMINALS. IF MOTOR DOES NOT

RUN, REPLACE MOTOR.

8K - 4 WIPER AND WASHER SYSTEMS LH

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...