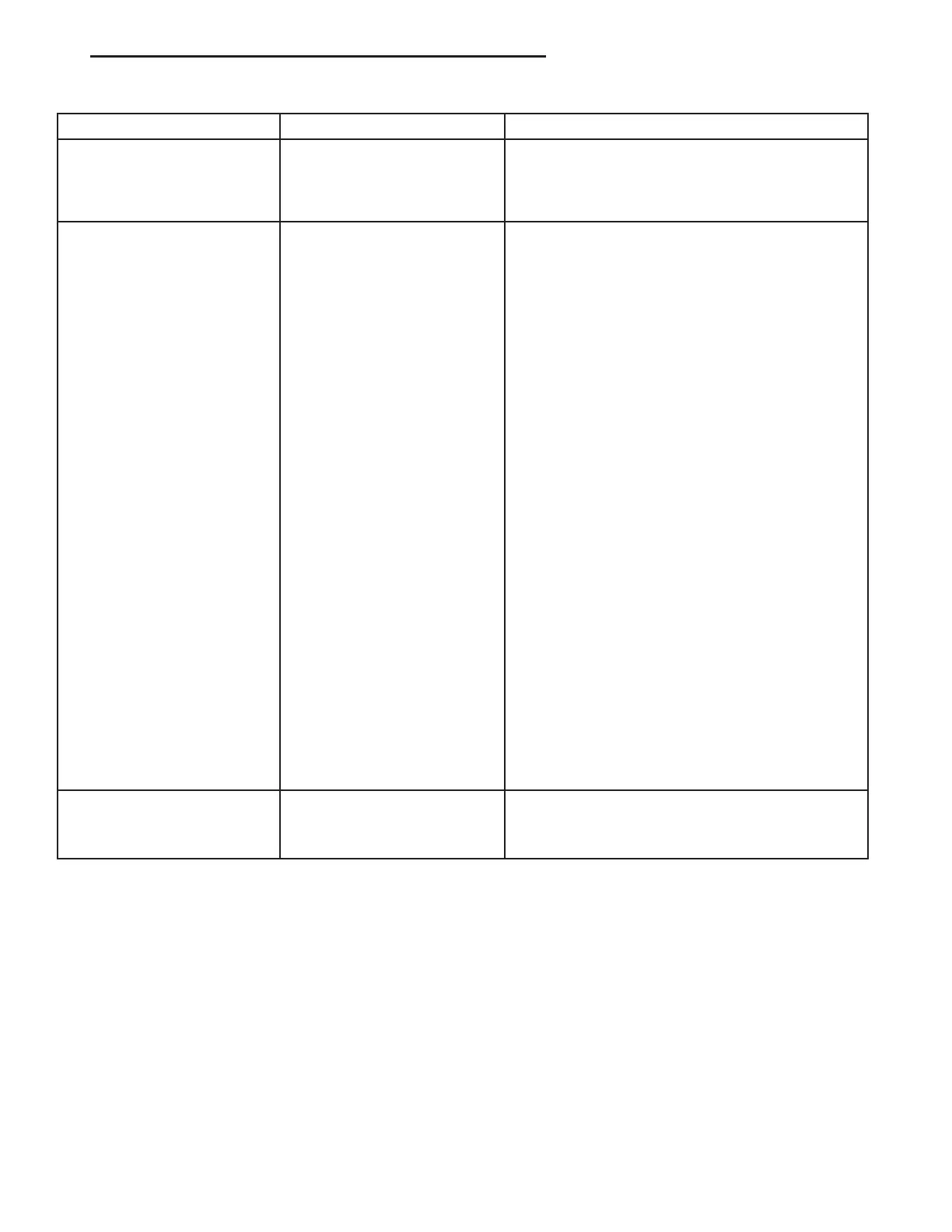

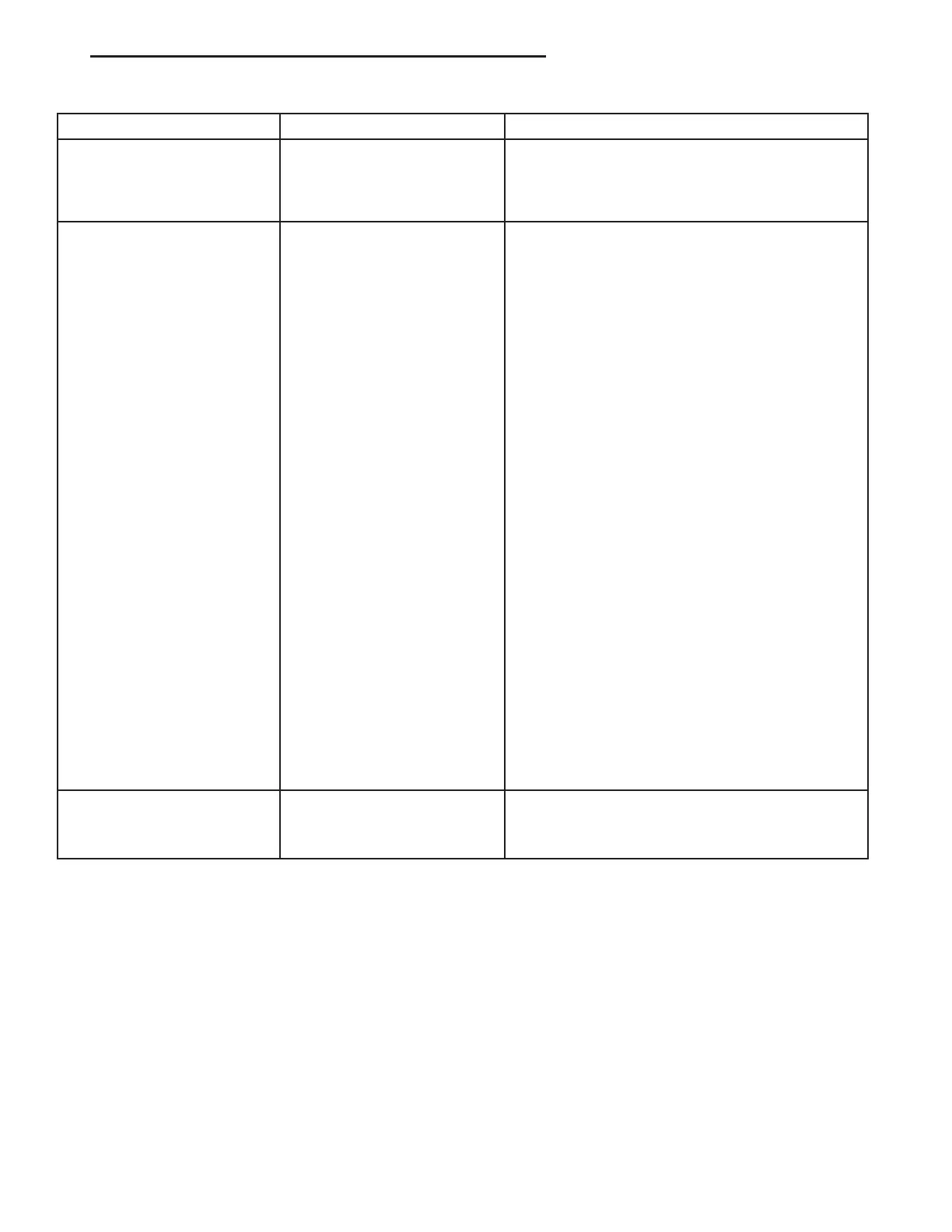

CONDITION POSSIBLE CAUSE CORRECTION

WASHER FLUID LEVEL

INDICATOR INOPERATIVE

1. LOOSE FLUID LEVEL

SENSOR CONNECTOR.

2. FLUID LEVEL SENSOR

SWITCH OPEN OR

DEFECTIVE.

1. PROPERLY SEAT CONNECTOR TO SWITCH.

2. ASSURE SENSOR FLOAT SWITCH IS CLOSED

(DOWN POSITION). APPLY OHMMETER TO

SWITCH TO CHECK FOR COMPLETE CIRCUIT. IF

NOT O. K., REPLACE SWITCH.

HEADLAMP WASHER

SYSTEM WILL NOT FLOW

WASHER FLUID

1. NO WASHER FLUID IN

RESERVOIR.

2. JUNCTION BLOCK FUSE

#5 BLOWN.

3. HEADLAMP WASHER

HOSE NOT FLOWING FLUID.

4. MOTOR CONNECTOR

LOOSE.

5. MOTOR CONNECTOR

TERMINALS BENT.

6. OPEN POWER CIRCUIT

TO SWITCH.

7. OPEN OR DEFECTIVE

WIPER / WASHER SWITCH.

8. OPEN POWER CIRCUIT

TO MOTOR.

9. OPEN OR DEFECTIVE

MOTOR GROUND CIRCUIT.

10. OPEN CIRCUIT IN

HEADLAMP WASHER

MOTOR.

11. SEIZED MOTOR

BEARINGS.

12. DEFECTIVE HEADLAMP

WASHER RELAY.

1. FILL RESERVOIR.

2. SHORT CIRCUIT BETWEEN JUNCTION BLOCK

FUSE #5 AND WIPER SWITCH TERMINAL #1.

SHORT IN WIPER SWITCH. IF NOT OK, REPAIR

CIRCUIT OR REFER TO WIPER / WASHER

SWITCH DIAGNOSTIC PROCEDURES.

3. ASSURE WASHER HOSE IS NOT PINCHED,

LOOSE, BROKEN, OR DISCONNECTED. IF NOT

OK, PROPERLY ROUTE OR REPAIR WASHER

HOSE.

4. PROPERLY SEAT CONNECTOR TO MOTOR.

5. REPAIR TERMINALS AND PROPERLY SEAT

CONNECTOR TO MOTOR.

6. OPEN OR DEFECTIVE CIRCUIT BETWEEN

JUNCTION BLOCK FUSE #5 AND WASHER

SWITCH CONNECTOR TERMINAL #1. IF NOT OK,

REPAIR CIRCUIT.

7. CONNECT AN OHMMETER ACROSS WIPER /

WASHER SWITCH TERMINAL #1 AND #2 AND

DEPRESS WASHER BUTTON AND CHECK FOR

CONTINUITY. IF NOT OK, REFER TO WIPER /

WASHER SWITCH DIAGNOSTIC PROCEDURES.

8. OPEN OR DEFECTIVE CIRCUIT BETWEEN

WIPER / WASHER SWITCH CONNECTOR

TERMINAL #2 AND MOTOR CONNECTOR

TERMINAL #1. IF NOT OK, REPAIR CIRCUIT.

9. OPEN OR DEFECTIVE CIRCUIT BETWEEN

WASHER MOTOR CONNECTOR GROUND

TERMINAL #2 AND LEFT HEADLAMP GROUND

#5 OR ENGINE GROUND #1 OR 2.

10. CHECK FOR AN OPEN CIRCUIT ON MOTOR

BETWEEN POWER TERMINAL #1 AND GROUND

TERMINAL #2. IF NOT OK, REPLACE WASHER

MOTOR.

11. APPLY DIRECT BATTERY VOLTAGE TO

MOTOR TERMINALS. IF MOTOR DOES NOT

RUN, REPLACE MOTOR.

REPLACE THE HEADLAMP WASHER RELAY.

ONE HEADLAMP WASHER

NOZZLE WILL NOT FLOW

WASHER FLUID

1. HEADLAMP WASHER

HOSE NOT FLOWING FLUID.

2. PLUGGED HEADLAMP

WASHER NOZZLE.

1. REPAIR OR REPLACE THE HEADLAMP

WASHER HOSE.

2. REPLACE HEADLAMP WASHER NOZZLE.

SERVICE PROCEDURES

HEADLAMP WASHER SYSTEM PRIMING

PROCEDURE

The headlamp washer system may loose it’s prime

when the system is serviced. The following procedure

must be used to prime the headlamp washer system.

A DRB III must be used for this priming procedure.

CAUTION: Do not allow washer fluid to spray on

hot engine with the hood up.

CAUTION: Do not stand near the headlamp washer

nozzles when actuating the headlamp washer sys-

tem. The washer fluid comes out of the nozzles at

high pressure.

(1) Connect a DRB III.

(2) Go to the “BODY” menu.

(3) Go to the “ACTUATER” menu.

(4) Actuate the “HEADLAMP WASHER” actuator

until the headlamp washer system is properly

primed.

CAUTION: Do not actuate the headlamp washers

longer that 4 seconds at a time. Allow pump to cool

prior to next attempt. Damage to the headlamp

washer pump may occur.

LH WIPER AND WASHER SYSTEMS 8K - 3

DIAGNOSIS AND TESTING (Continued)

2000 LHS, 300M, CONCORDE AND INTREPID

Loading...

Loading...