CAUTION: Main bearings are select fit. Refer to

Crankshaft Main Bearing Fitting in this section for

proper bearing selections.

(1) Lubricate upper main bearing halves with

engine oil (Fig. 88).

CAUTION: When installing crankshaft, use care not

to damage bearing surfaces on the crankshaft.

(2) Install crankshaft.

NOTE: Make sure that the coated and oil groove

side of crankshaft thrust washer faces the crank-

shaft thrust surface.

(3) Push crankshaft forward. Lubricate and install

the front thrust washer by rolling the thrust washer

onto the machined shelf between the No. 3 upper

main bulk head and crankshaft thrust surface (Fig.

89).

(4) Move crankshaft rearward. Lubricate and

install the rear thrust washer by rolling the thrust

washer onto the machined shelf between the No. 3

upper main bulk head and crankshaft thrust surface.

(5) Lubricate lower main bearings with engine oil.

(6) Install main bearings and caps.

NOTE: Lubricate main bearing cap bolts with

engine oil before installation.

The main bearing cap bolts must be tightened in

the proper sequence. First the inner main cap bolts,

secondly the windage tray bolts, and lastly the main

cap tie (horizontal) bolts.

(7) Install the inside main bearing cap bolts and

tighten to 20 N·m + 1/4 Turn (15 ft. lbs. + 1/4 Turn)

(Fig. 90).

(8) Measure crankshaft end play. Refer to Service

Procedures—Crankshaft Bearing Installation for pro-

cedure.

(9) Install connecting rods and measure side clear-

ance. Refer to Service Procedures—Connecting Rod

Bearing Installation for procedures.

(10) Install windage tray (Fig. 91). Lubricate bolts

with engine oil and tighten to 27 N·m + 1/4 Turn (20

ft. lbs. + 1/4 turn).

(11) Install the main cap tie (horizontal) bolts and

tighten to 28 N·m (250 in. lbs.) (Fig. 90).

(12) Install rear crankshaft oil seal retainer and

oil seal. Refer to procedures in this section.

(13) Install oil pump assembly. Refer to procedure

in this section.

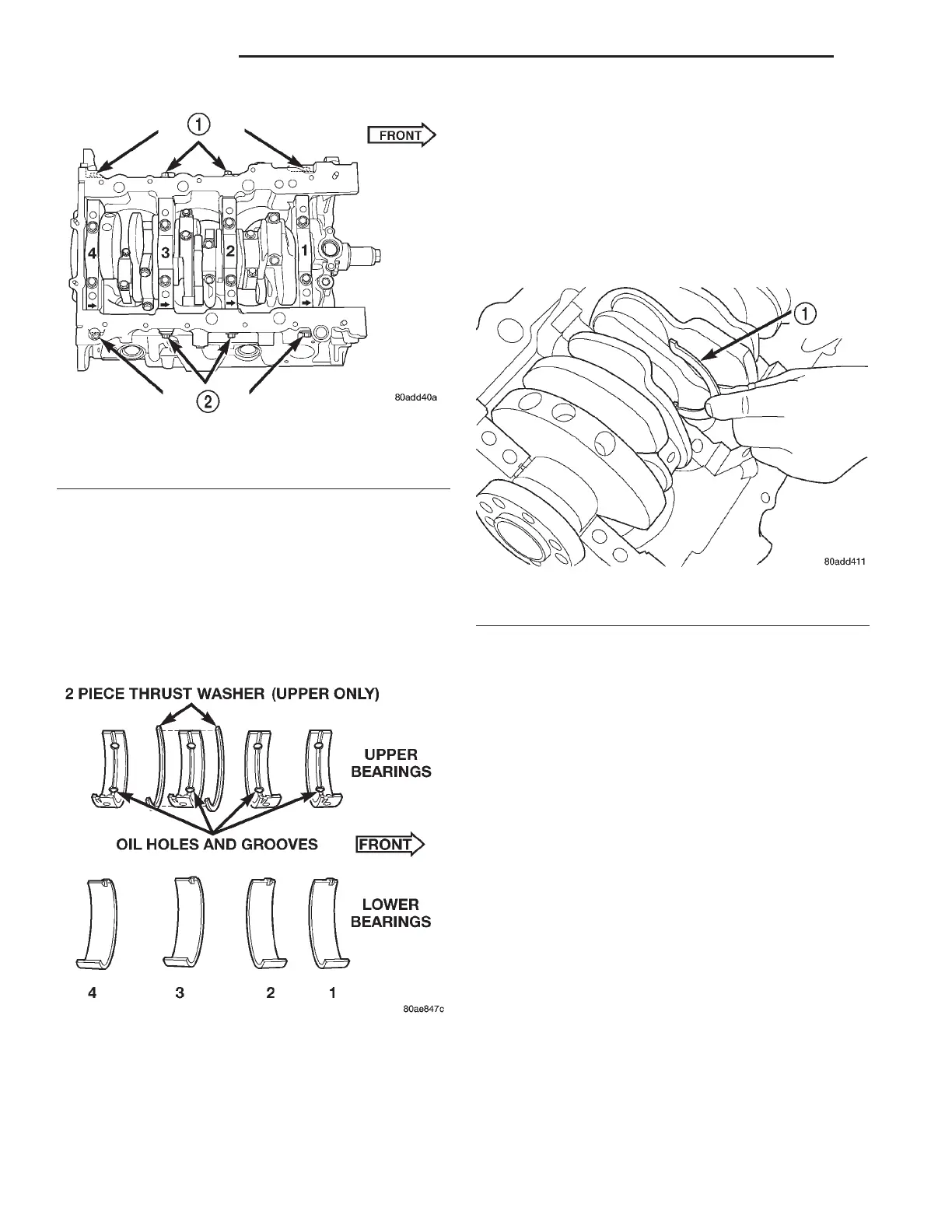

Fig. 87 Main Bearing Cap Identification

1 – TIE BOLTS

2 – TIE BOLTS

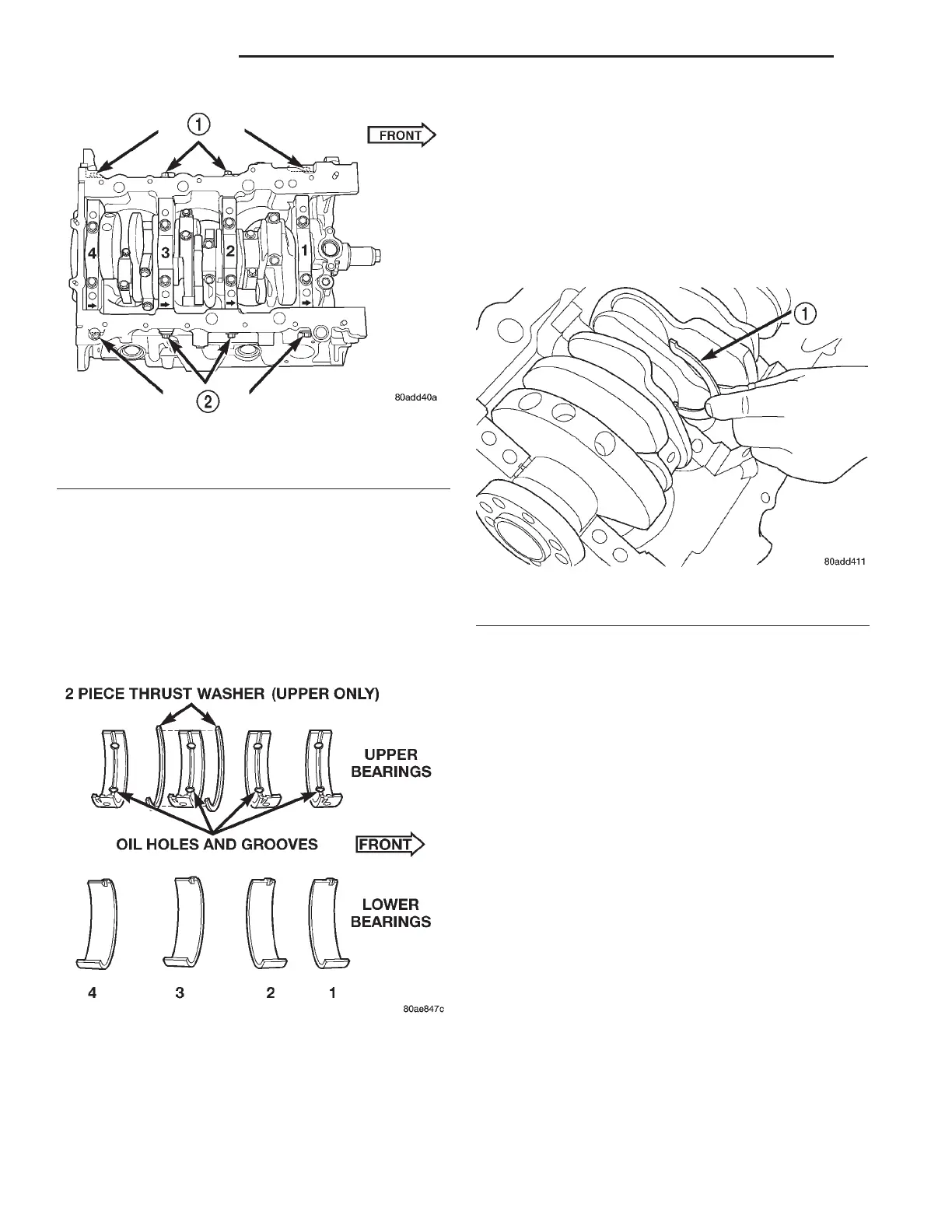

Fig. 88 Main Bearing Identification

Fig. 89 Thrust Washer—Installation

1 – FRONT THRUST WASHER

9 - 56 2.7L ENGINE LH

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...