The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

When using the DRB lllt scan tool, refer to the

proper Body Diagnostic Procedures Manual for Diag-

nosis and Testing.

WINDSHIELD WASHER SYSTEM

DESCRIPTION

All models are equipped with electric operated

windshield washer pumps. The electric pump assem-

bly is mounted with a grommet directly to the reser-

voir.

The windshield washer system is controlled by a

switch located on the multi-functin switch stalk. The

multi-function switch is located on the steering col-

umn behind the steering wheel.

OPERATION

The wash function can be accessed in the OFF

position of the wiper control switch. Wash switch

must be pressed for at least 0.5 second to get the

wipe after wash. Holding the wash button depressed

when the switch is in the OFF position will operate

the wipers and washer motor pump continuously

until the washer button is released. Releasing the

button will stop the washer pump but the wipers will

complete the current wipe cycle, followed by an aver-

age of two more wipe cycles (61) before the wipers

park and the module turns off. If the wash switch is

pressed momentarily with the wipers in the OFF or

INTERMITTENT position, a pulse wipe cycle consist-

ing of two wipes will occur.

Fluid is gravity fed from the reservoir to the motor.

The fluid is forced by the pump through rubber hoses

to the hood mounted nozzles which direct the fluid

streams to the windshield. The one way flow check

valves are located in each hood nozzle. The purpose

of the check valves is to improve fluid flow response

time and to prevent excessive washer fluid staining

the surface of the hood. The hood mounted nozzles

distribute washer fluid on the surface of the wind-

shield. The nozzles are adjustable, refer to the

Washer Nozzle Adjusting Procedures. The pump and

reservoir are serviced as separate assemblies.

WIPER BLADES

DESCRIPTION

The wiper blades are a rubber element with a steel

vertebrae that are mounted on the end of the wind-

shield wiper arm and sweep across the front wind-

shield to clear it of water, snow, and debris.

OPERATION

When the wiper blade rubber element is exposed to

the weather for a long period of time, it tends to lose

wiping ability. Periodic cleaning of the wiper blade

element is suggested to remove the accumulation of

salt and road film. The wiper blades, arms, and

windshield should be cleaned with a sponge or cloth

and a mild detergent or non-abrasive cleaner. If the

blades continue to streak or smear, they should be

replaced. The driver blade element is 600 mm in

length and the passenger blade element is 550 mm in

length.

DIAGNOSIS AND TESTING

INTERMITTENT WIPER FUNCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

STEERING WHEEL OR COLUMN REMOVAL PROCE-

DURES.

The intermittent wiper function is controlled by

the Body Control Module (BCM), located in the left

side of the instrument panel, attached to the Junc-

tion Block (Fig. 3). If the Body Control Module is

determined to be the problem, refer to Group 8E,

Instrument Panels and Systems, for replacement pro-

cedures.

MULTI-FUNCTION/WIPER SWITCH

To test the multi-function/wiper switch, first dis-

connect the switch wires from the body wiring in the

steering column (Fig. 4). Using an ohmmeter, test for

continuity between the terminals of the switch, as

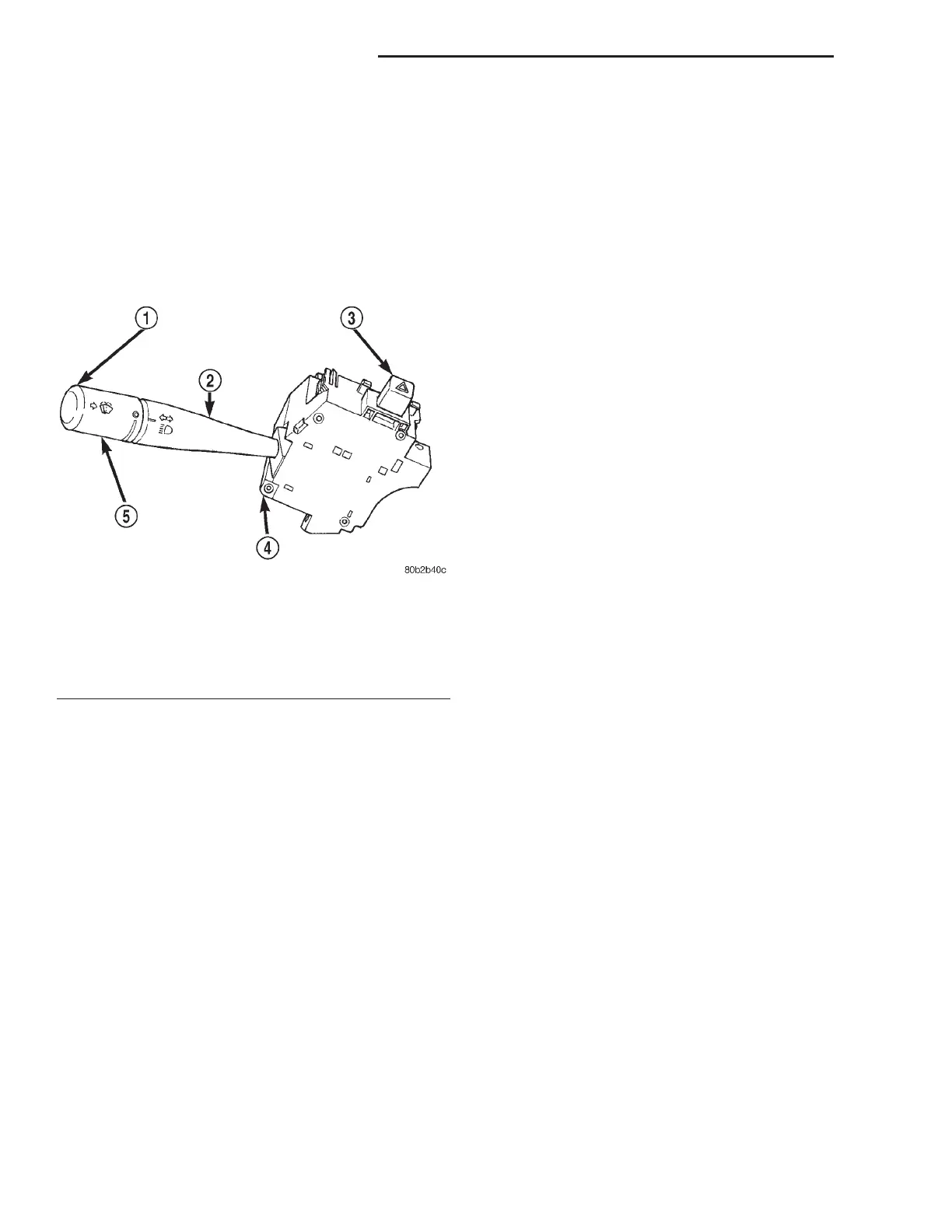

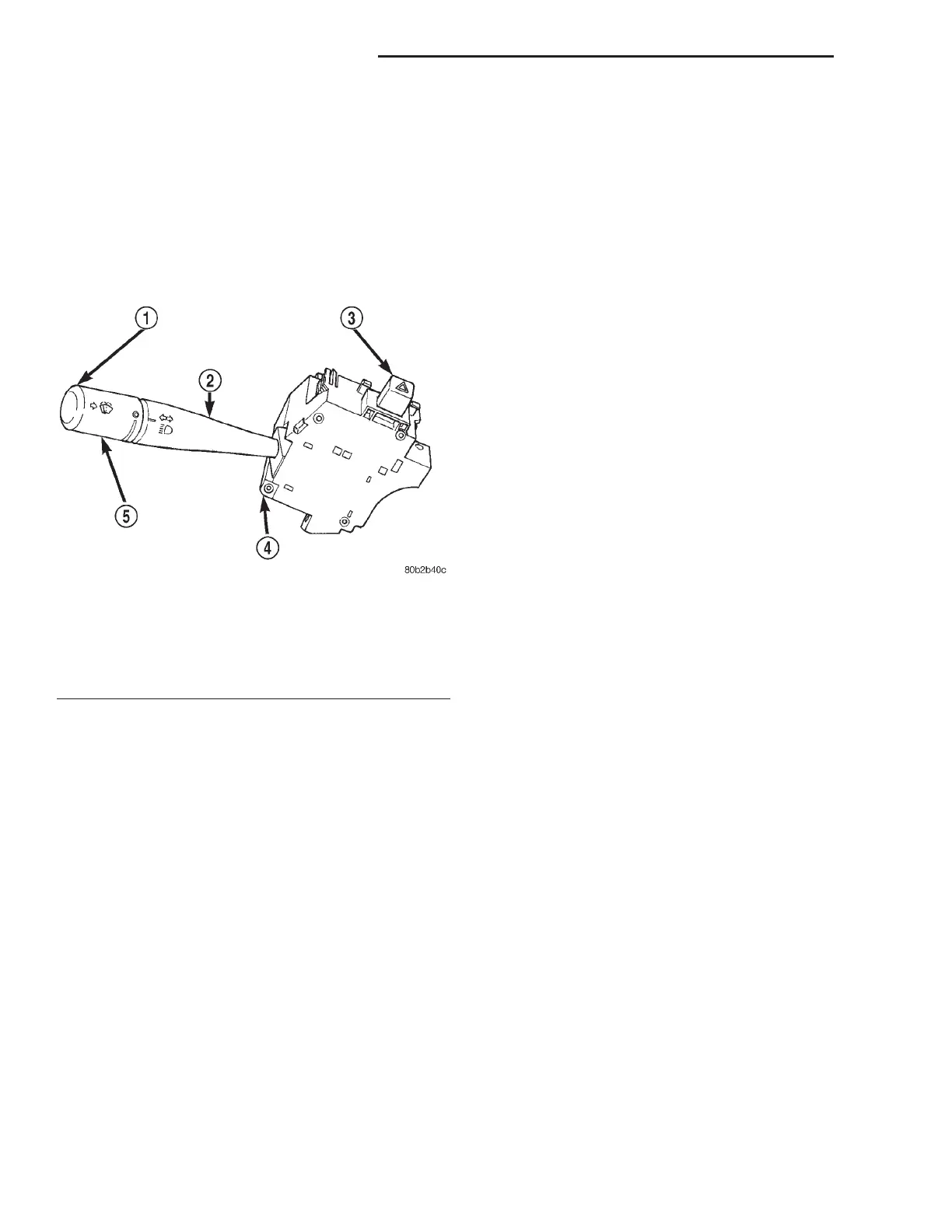

Fig. 2 Windshield Washer Switch

1 – WINDSHIELD WASHER BUTTON

2 – CONTROL STALK (BEAM SELECT)

3 – HAZARD WARNING BUTTON

4 – MULTI-FUNCTION SWITCH

5 – WINDSHIELD WIPER CONTROL

8K - 2 WIPER AND WASHER SYSTEMS LH

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...