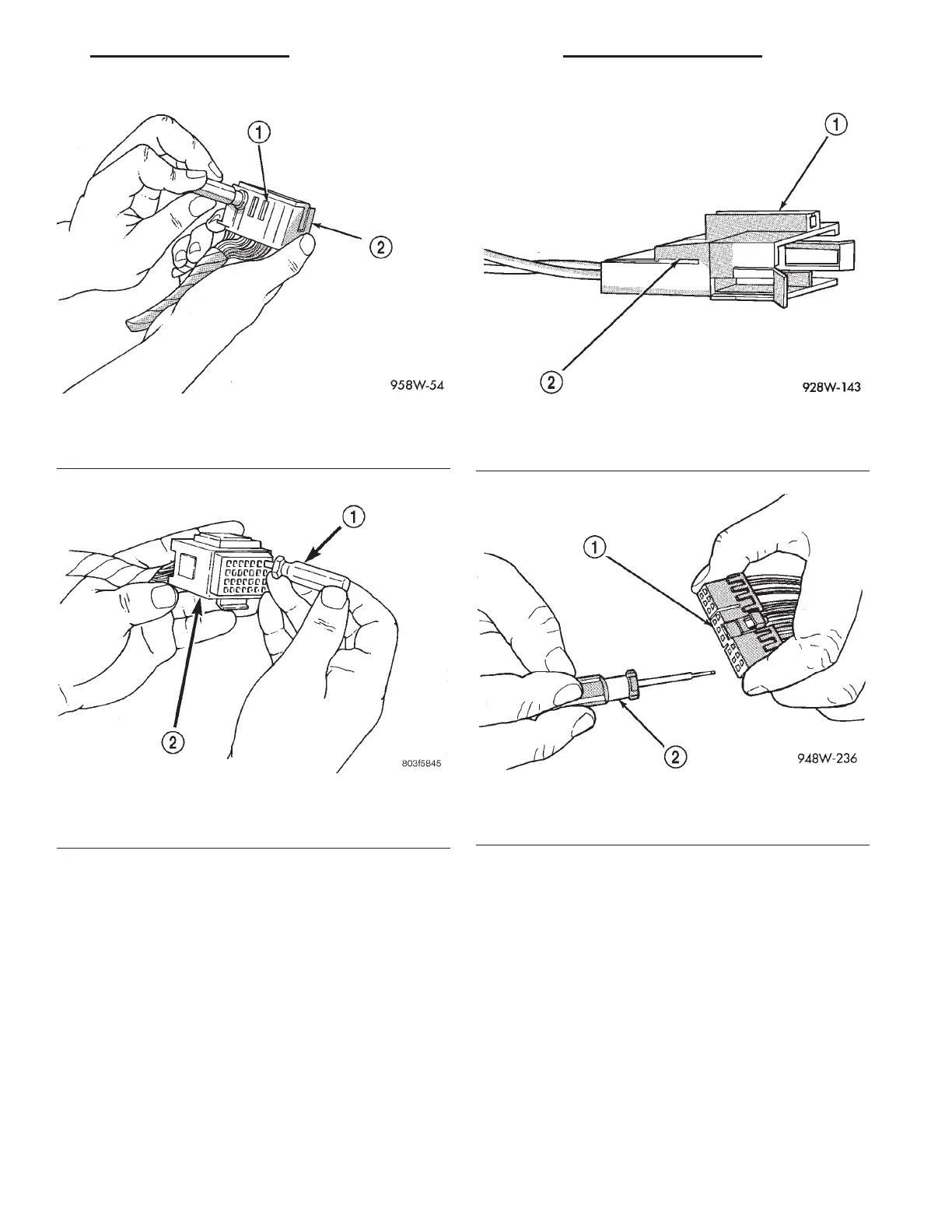

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 17) (Fig. 18).

(5) Cut the wire 6 inches from the back of the con-

nector.

(6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires.

(11) Push the two ends of wire together until the

strands of wire are close to the insulation.

(12) Twist the wires together.

(13) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge, if

required, and reconnect the connector to its mating

half/component.

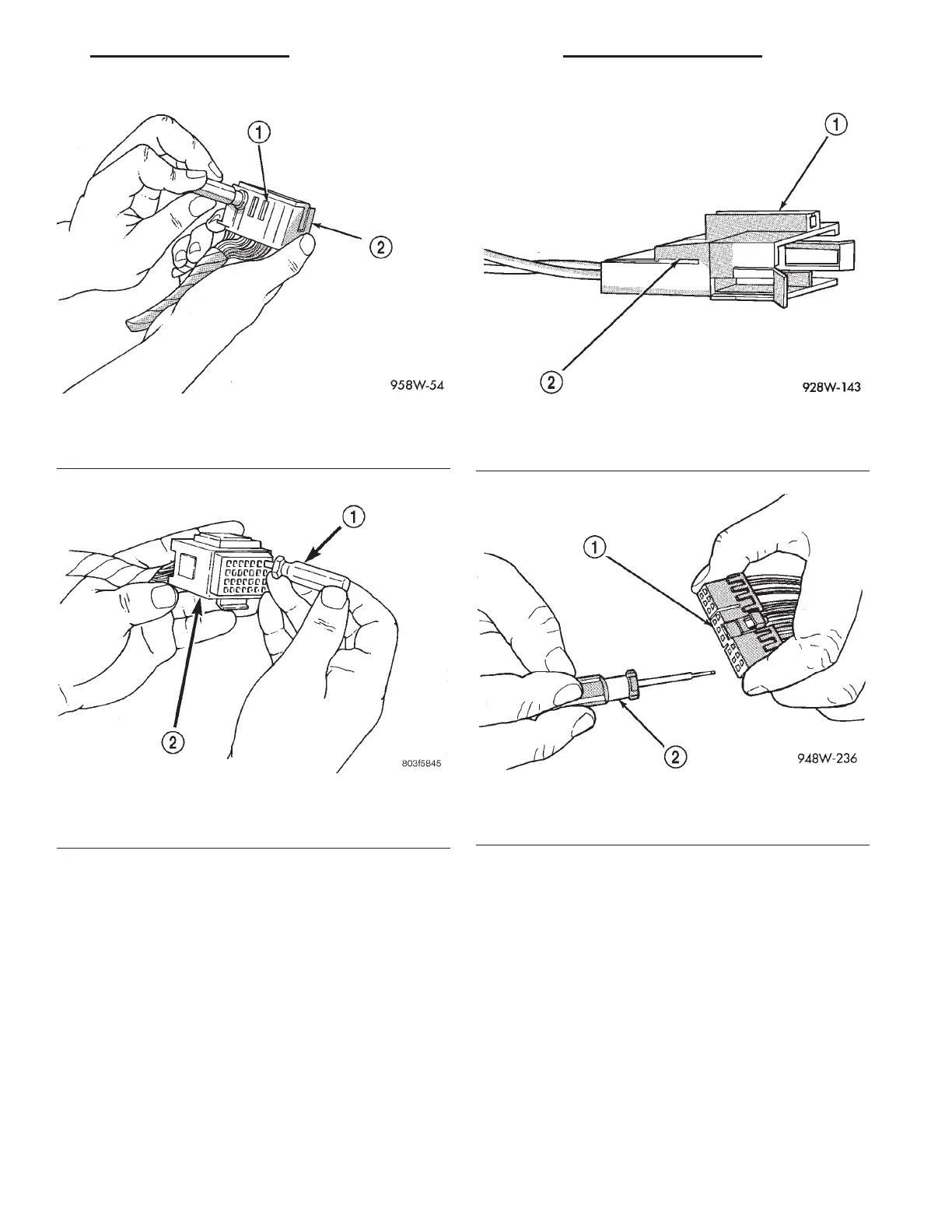

Fig. 14 Augat Connector Repair

1 – LOCKING TAB

2 – CONNECTOR

Fig. 15 Using Special Tool 6932

1 – SPECIAL TOOL 6932

2 – CONNECTOR

Fig. 16 Connector Locking Wedge Tab (Typical)

1 – CONNECTOR

2 – CONNECTOR LOCKING WEDGE TAB

Fig. 17 Terminal Removal

1 – CONNECTOR

2 – FROM SPECIAL TOOL KIT 6680

LH 8W - 01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)

Loading...

Loading...