Two different ICU’s (HCU and CAB) are used on

this vehicle depending on whether or not the vehicle

is equipped with traction control. The HCU on a

vehicle equipped with traction control has a valve

block that is approximately one inch longer than a

HCU on a vehicle that is equipped with ABS only.

The ABS-only ICU consists of the following compo-

nents: the CAB, eight (build/decay) solenoid valves

(four inlet valves and four outlet valves), valve block,

fluid accumulators, a pump, and an electric motor.

The ABS-with traction control ICU consists of the

following components: the CAB, eight (build/decay)

solenoid valves (four inlet valves and four outlet

valves), two traction control (ASR) valves, two

hydraulic shuttle valves, valve block, fluid accumula-

tors, a pump, and an electric motor.

The replaceable components of the ICU are the

HCU and the CAB. No attempt should be made to

service any individual components of the HCU or

CAB.

OPERATION

For information of the ICU, refer to these individ-

ual components of the ICU:

• CONTROLLER ANTILOCK BRAKE (CAB)

• HYDRAULIC CONTROL UNIT (HCU)

For information on the ICU’s hydraulic circuits,

refer to HYDRAULIC CIRCUITS AND VALVE

OPERATION which can be found elsewhere in this

section.

CONTROLLER ANTILOCK BRAKE (CAB)

DESCRIPTION

The controller antilock brake (CAB) is a micropro-

cessor-based device which monitors the ABS system

during normal braking and controls it when the vehi-

cle is in an ABS stop. The CAB is mounted to the

bottom of the HCU (Fig. 1). The CAB uses a 25-way

electrical connector on the vehicle wiring harness.

The power source for the CAB is through the ignition

switch in the RUN or ON position. The CAB is on

the PCI bus.

OPERATION

The primary functions of the CAB are to:

• Monitor the antilock brake system for proper

operation.

• Detect wheel locking or wheel slipping tenden-

cies by monitoring the speed of all four wheels of the

vehicle.

• Control fluid modulation to the wheel brakes

while the system is in an ABS mode.

• Store diagnostic information.

• Provide communication to the DRB scan tool

while in diagnostic mode.

• Illuminate the amber ABS warning lamp.

• (with traction control only) Illuminate the TRAC

ON lamp in the message center on the instrument

panel when a traction control event occurs.

• (with traction control only) Illuminate the TRAC

OFF lamp when the amber ABS warning lamp illu-

minates.

The CAB constantly monitors the antilock brake

system for proper operation. If the CAB detects a

fault, it will turn on the amber ABS warning lamp

and disable the antilock braking system. The normal

base braking system will remain operational.

NOTE: If the vehicle is equipped with traction con-

trol, the TRAC OFF lamp will illuminate anytime the

amber ABS warning lamp illuminates.

The CAB continuously monitors the speed of each

wheel through the signals generated by the wheel

speed sensors to determine if any wheel is beginning

to lock. When a wheel locking tendency is detected,

the CAB commands the CAB command coils to actu-

ate. The coils then open and close the valves in the

HCU that modulate brake fluid pressure in some or

all of the hydraulic circuits. The CAB continues to

control pressure in individual hydraulic circuits until

a locking tendency is no longer present.

The CAB contains a self-diagnostic program that

monitors the antilock brake system for system faults.

When a fault is detected, the amber ABS warning

lamp is turned on and the fault diagnostic trouble

code (DTC) is then stored in a diagnostic program

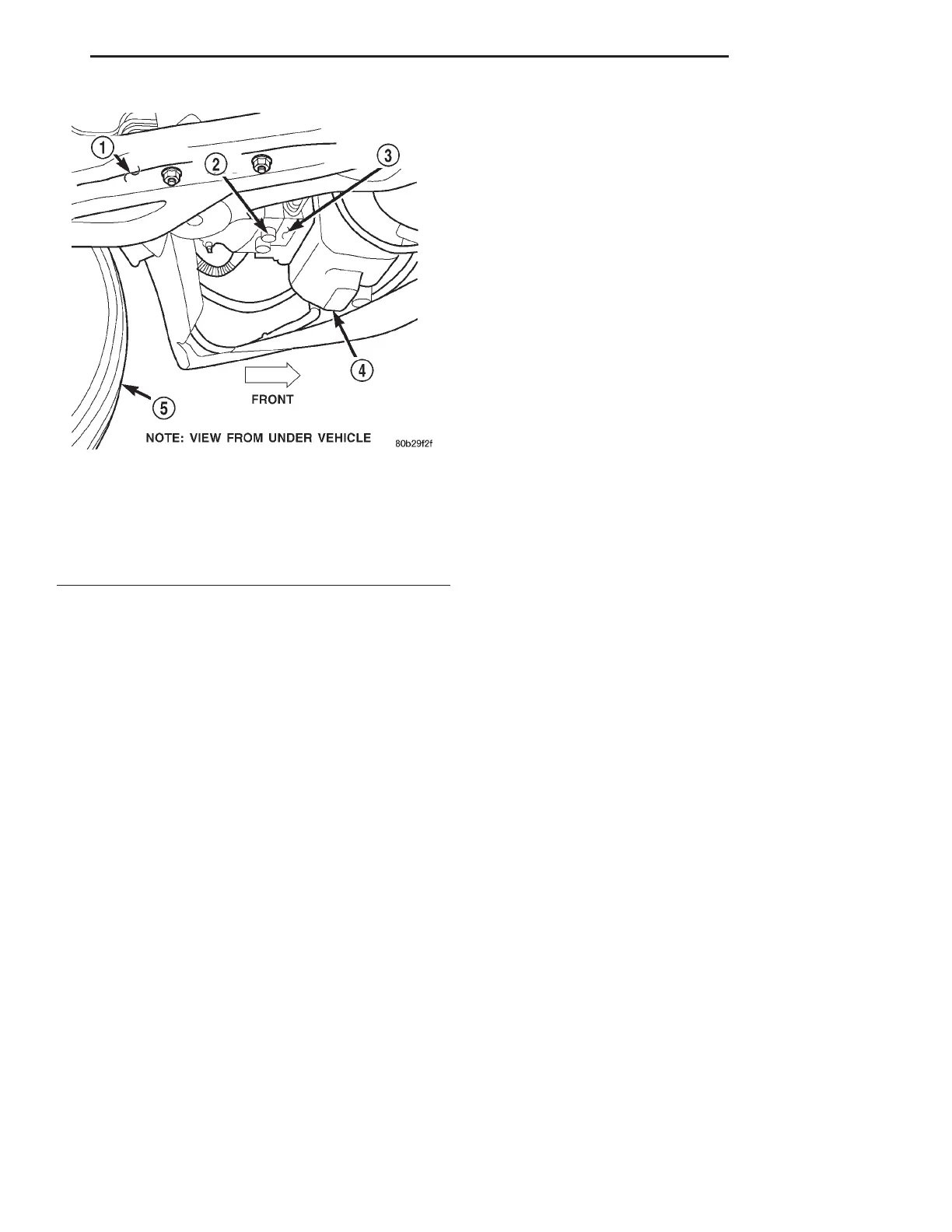

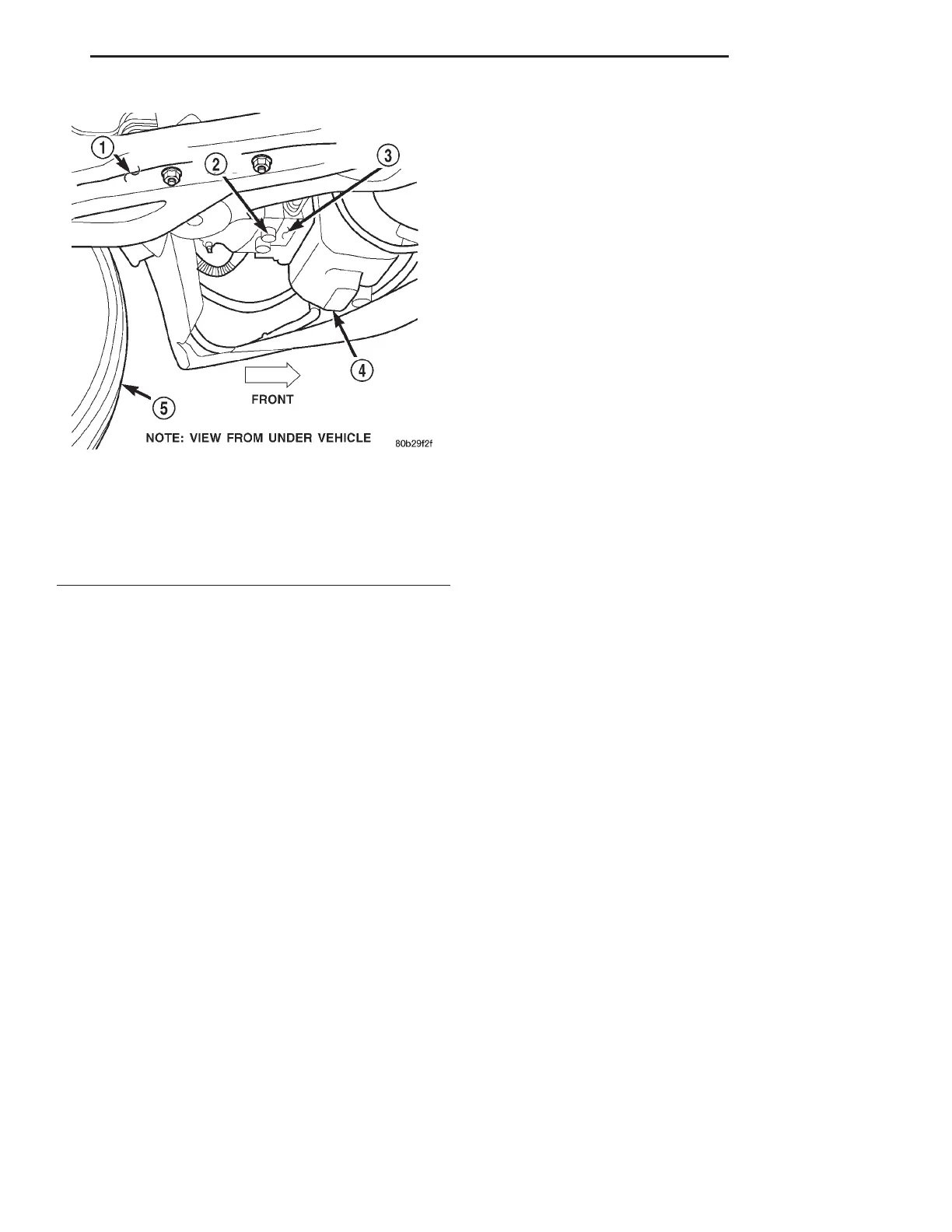

Fig. 2 Integrated Control Unit (HCU And CAB)

Location

1 – ENGINE CRADLE

2 – HCU

3 – CONTROLLER ANTILOCK BRAKE (CAB)

4 – BOTTOM OF WINDSHIELD WASHER RESERVOIR

5 – LEFT FRONT TIRE

LH BRAKES 5 - 57

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...