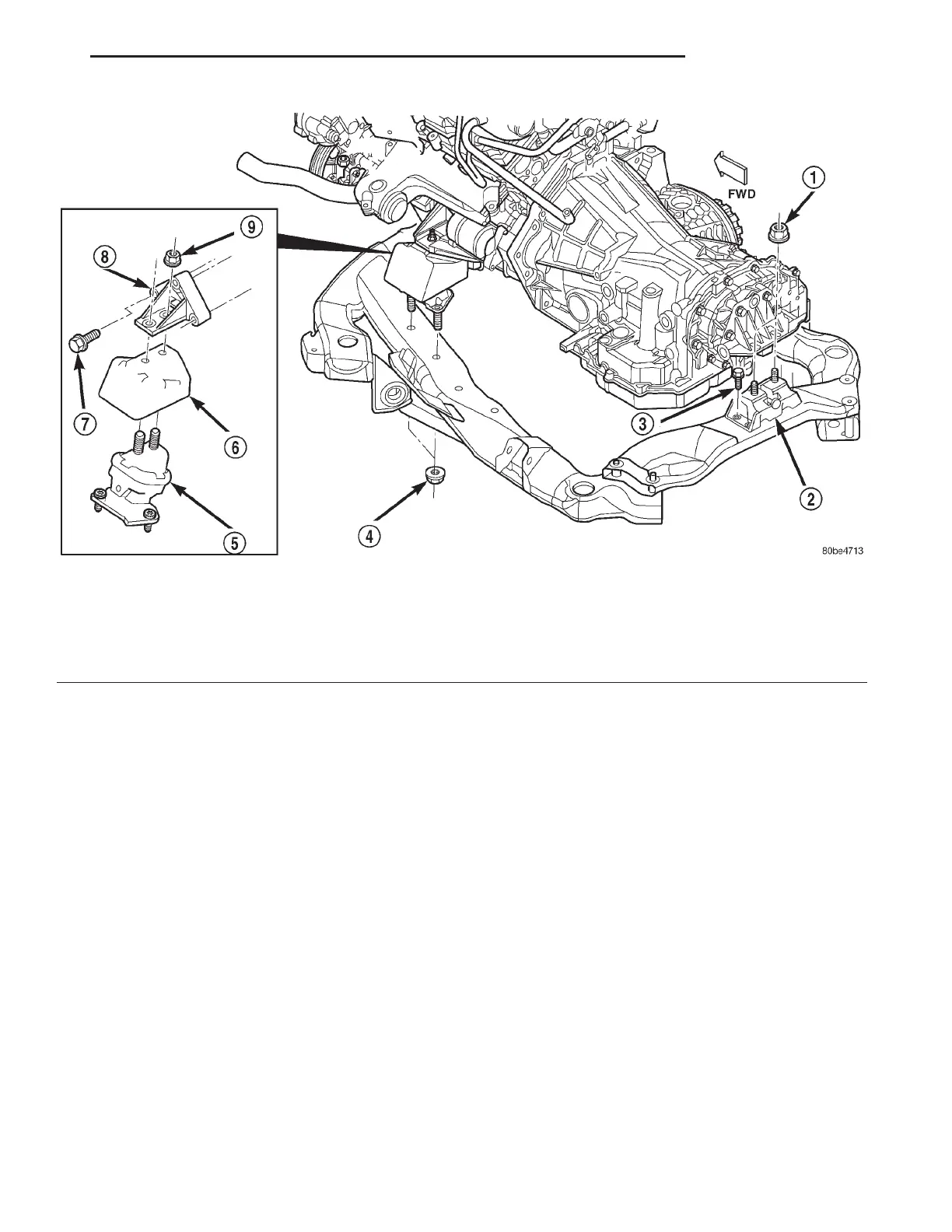

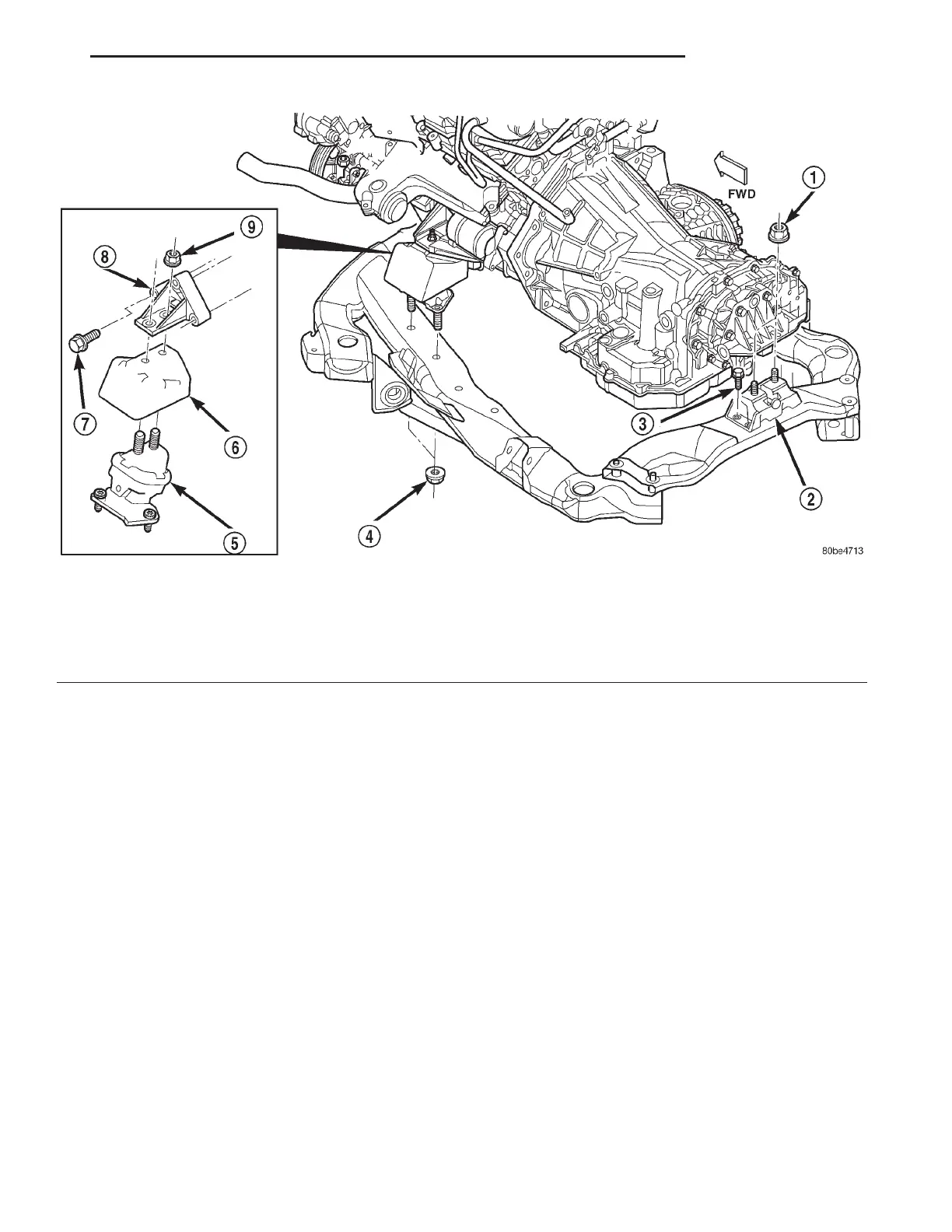

REMOVAL AND INSTALLATION

ENGINE MOUNTS—LEFT AND RIGHT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the isolator attaching nuts from top of

the mounting bracket (Fig. 39).

(3) Support the engine with a jack and a block of

wood across the full width of the oil pan.

(4) Remove the lower attaching nuts from the bot-

tom of the isolator to the frame (Fig. 39).

(5) Raise engine carefully with jack enough to

remove the isolator with heat shield from its mount.

INSTALLATION

(1) Install isolator mount with heat shield onto the

frame.

(2) Lower the engine onto the isolator mount.

(3) Remove jack from vehicle.

(4) Tighten the isolator to frame nuts to 61 N·m

(45 ft. lbs.) (Fig. 39).

(5) Install the upper attaching nuts to mount and

tighten to 61 N·m (45 ft. lbs.) (Fig. 39).

(6) Lower vehicle.

ENGINE HYDRO-MOUNT ISOLATORS

Engine hydro-mounts may show surface cracks,

this will not effect performance and hydro-mount

should not be replaced. Only replace the engine

hydro-mounts when leaking fluid:

• Driveshaft Diagnosis. Refer to DIFFERENTIAL

AND DRIVELINE.

• Any front end structural damage (after repair).

• Isolator replacement.

ENGINE MOUNT—REAR

REMOVAL

(1) Raise vehicle on hoist.

(2) Support transaxle with a jack.

(3) Remove isolator nuts from the mount to tran-

saxle mount bracket (Fig. 39).

(4) Remove rear mount isolator bolts to crossmem-

ber and remove mount (Fig. 39).

Fig. 39 Engine Mounting—Right, Left, and Rear

1 – NUT

2 – REAR ISOLATOR

3 – BOLT

4 – NUT

5 – ISOLATOR

6 – HEAT SHIELD

7 – BOLT

8 – ENGINE MOUNT BRACKET

9 – NUT

LH 2.7L ENGINE 9 - 31

SERVICE PROCEDURES (Continued)

Loading...

Loading...