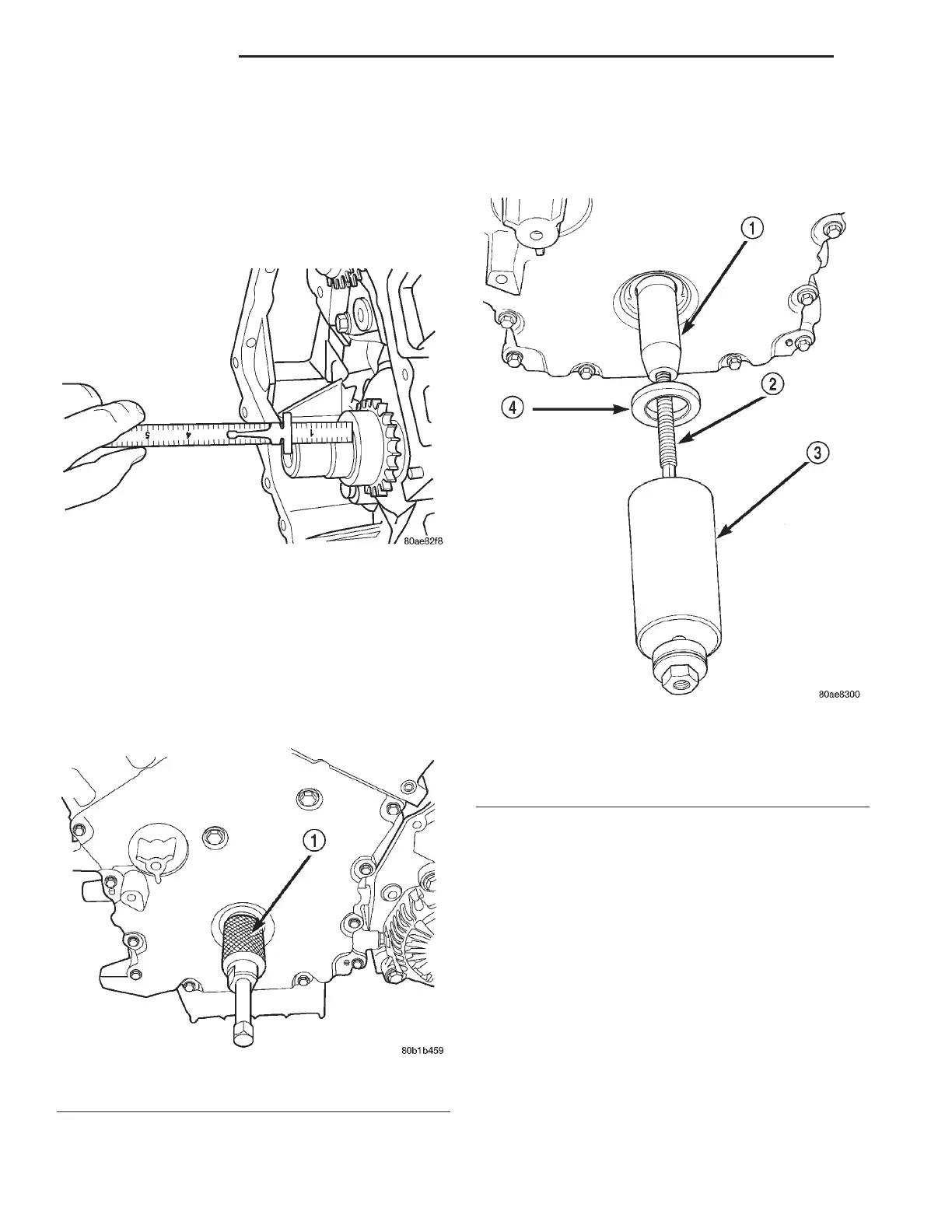

against crankshaft step flange. Use care not to rotate

crankshaft.

(2) Verify that crankshaft sprocket is installed to

proper depth by measuring from sprocket outer face

to end of crankshaft (Fig. 78). Measurement should

read: 39.05 60.50 mm (1.5374 60.020 in.).

(3) Install primary timing chain. Refer to proce-

dure in this section.

CRANKSHAFT OIL SEAL—FRONT

REMOVAL

(1) Remove crankshaft damper. Refer to procedure

in this section.

(2) Install Special Tool 8194, Insert into crankshaft

nose. Remove seal using Special Tool 6771, Remover

(Fig. 79).

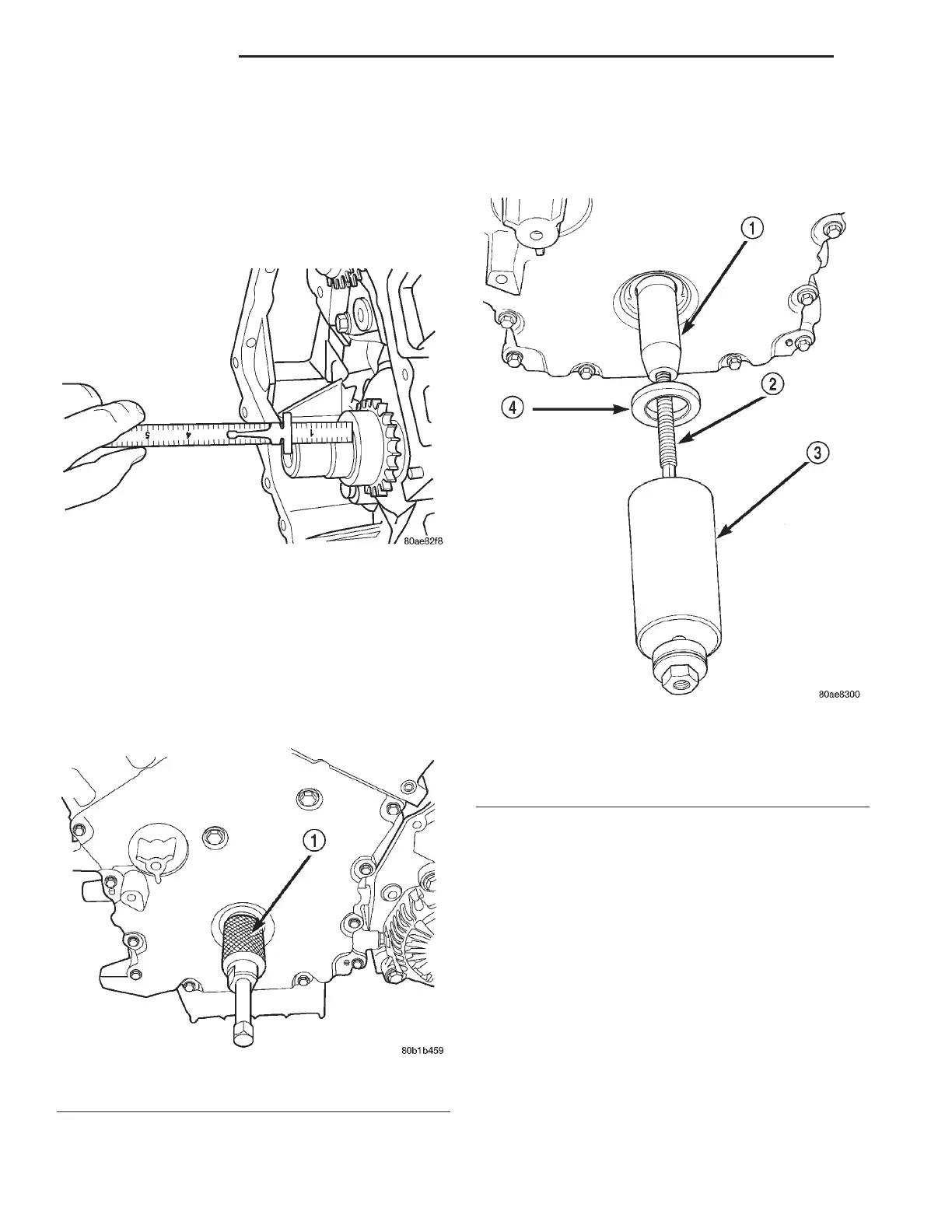

INSTALLATION

(1) Install new seal using Special Tools 6780-2

Sleeve, 6780-1 Installer, and 8179 Stud (Fig. 80).

(2) Install crankshaft damper.

CRANKSHAFT OIL SEAL—REAR

REMOVAL

(1) Remove transaxle from vehicle. Refer to TRAN-

SAXLE for procedure.

(2) Remove drive plate.

(3) Insert a 3/16” wide flat bladed screwdriver

between the dust lip and the metal case of the crank-

shaft seal. Angle the screwdriver (Fig. 81) through

the dust lip against the metal case of the seal. Pry

out seal.

CAUTION: Do not allow the screwdriver blade to

contact the crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

Fig. 78 Crankshaft Sprocket Depth Measurement

Fig. 79 Crankshaft Front Oil Seal—Removal

1 – SPECIAL TOOL 6771

Fig. 80 Crankshaft Front Oil Seal—Installation

1 – SPECIAL TOOL 6780–2

2 – SPECIAL TOOL 8179

3 – SPECIAL TOOL 6780–1

4 – SEAL

9 - 52 2.7L ENGINE LH

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...