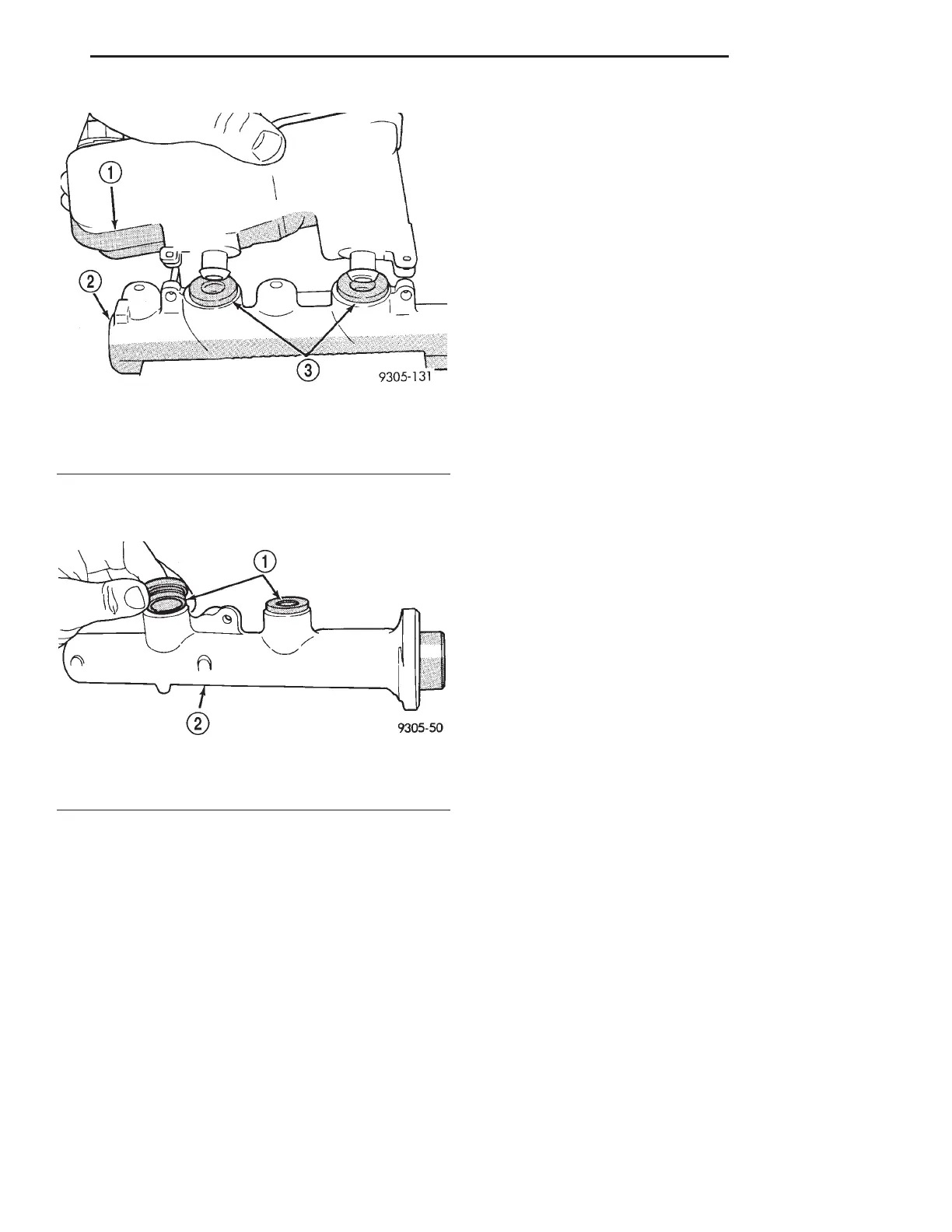

(7) Remove the master cylinder housing-to-reser-

voir grommets (Fig. 85).

ASSEMBLE

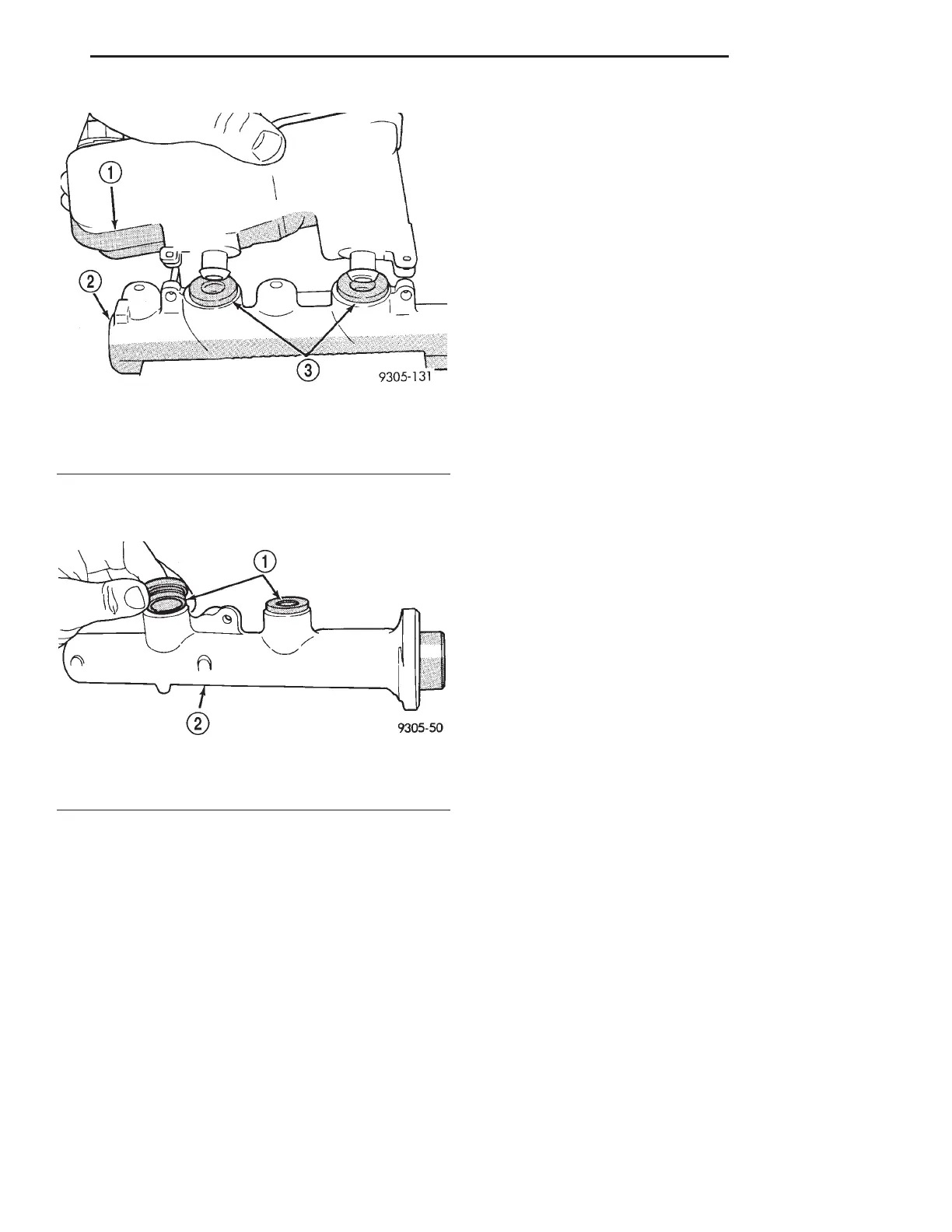

(1) Install new housing-to-reservoir grommets in

master cylinder housing (Fig. 85).

(2) Lubricate brake fluid reservoir mounting area

with clean brake fluid. Place reservoir in position

over grommets. Seat reservoir into sealing grommets

using a rocking motion while pushing down on reser-

voir.

(3) Make sure bottom of reservoir touches the top

of both sealing grommets.

(4) Install the 2 fluid reservoir to master cylinder

retaining pins (Fig. 83).

DISC BRAKE CALIPER (FRONT AND REAR)

CLEANING AND INSPECTION

Check for brake fluid leaks in and around dust

boot area and inboard brake pad, and for any rup-

tures, brittleness or damage to the piston dust boot.

If the dust boot is damaged, or a fluid leak is visible,

disassemble caliper assembly and install a new pis-

ton seal and dust boot, and piston if scored. Refer to

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Guide Pin Bush-

ing Service in Disc Brake Caliper Service in this sec-

tion of the service manual.

CALIPER GUIDE PIN BUSHING SERVICE

The double pin caliper uses a sealed for life bush-

ing and sleeve assembly. If required this assembly

can be serviced using the following procedure.

REMOVING CALIPER GUIDE PIN BUSHINGS

(1) Remove caliper from brake rotor (See Brake

Shoe Removal). Hang caliper assembly on a wire

hook away from the brake rotor.

(2) Push out and then pull the steel sleeve from

the inside of the bushing using your fingers as shown

in (Fig. 86).

(3) Using your fingers, collapse one side of the

bushing. Then pull on the opposite side to remove

the bushing from the brake caliper housing (Fig. 87).

INSTALLING CALIPER GUIDE PIN BUSHINGS

(1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 88).

(2) Insert the folded bushing into the caliper hous-

ing (Fig. 89). Do not use a sharp object to per-

form this step due to possible damage to the

bushing.

(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into

the caliper housing. Flanges should be seated evenly

on both sides of the bushing hole (Fig. 90).

(4) Lubricate the inside surfaces of the bushing

using Mopar, Silicone Dielectric Compound or an

equivalent.

(5) Install guide pin sleeve into one end of bushing

until seal area of bushing is past seal groove in

sleeve (Fig. 91).

Fig. 84 Removing Reservoir

1 – FLUID RESERVOIR

2 – MASTER CYLINDER

3 – SEALING GROMMETS

Fig. 85 Reservoir Sealing Grommets

1 – RESERVOIR SEALING GROMMETS

2 – MASTER CYLINDER

LH BRAKES 5 - 45

DISASSEMBLY AND ASSEMBLY (Continued)

2000 LHS, 300M, CONCORDE AND INTREPID

Loading...

Loading...