DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS

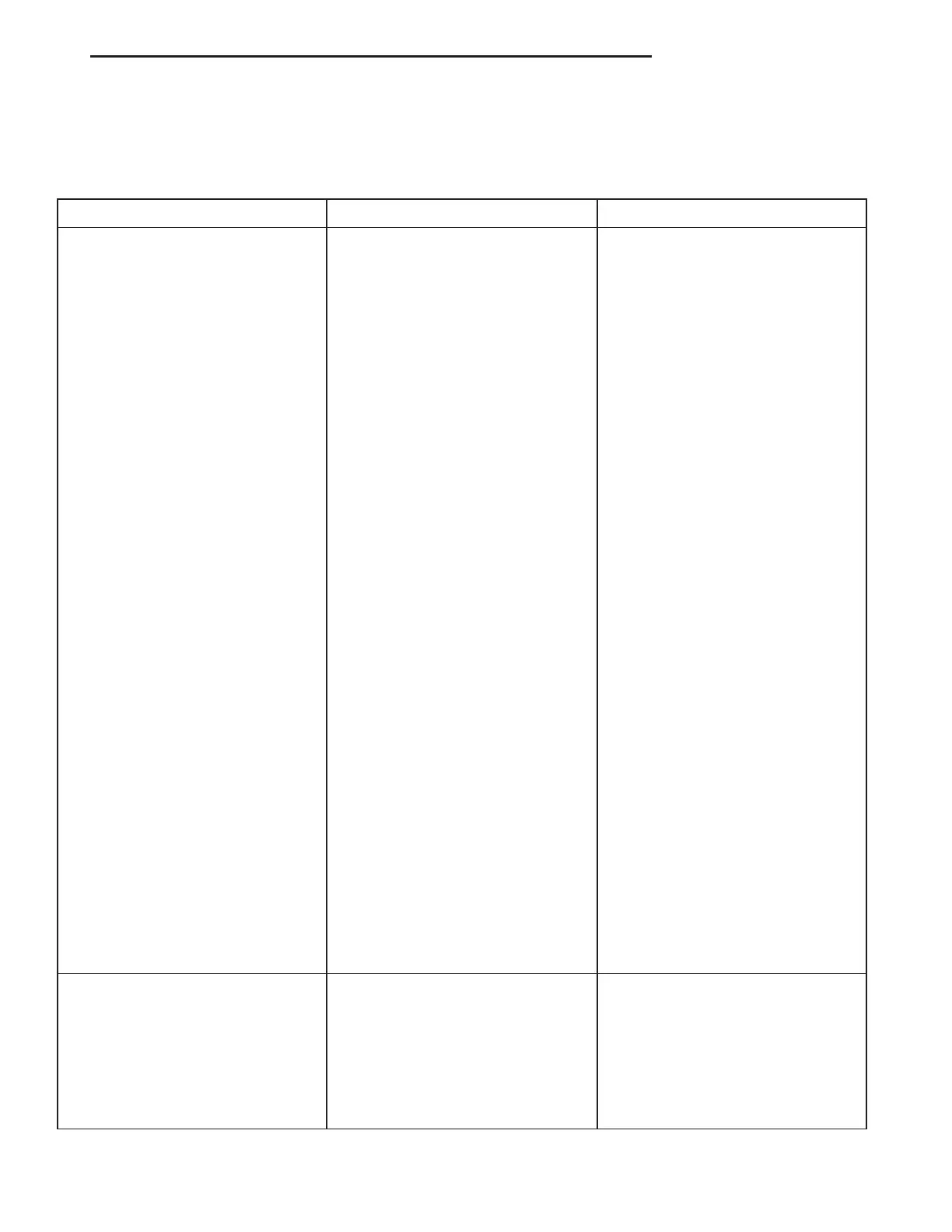

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READING

IS INCONSISTENT (FLUCTUATES,

CYCLES OR IS ERRATIC).

1. During cold weather operation

with the heater blower in the high

position, the gauge reading may

drop slightly. Fluctuation is also

influenced by loads, outside

temperature, and cycling of the air

conditioning system.

1. A normal condition. No correction

is necessary.

2. Temperature gauge or engine

sending unit sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.

2. Check operation of gauge and

repair if necessary. Refer to

INSTRUMENT PANEL AND

SYSTEMS.

3. Gauge reading rise when vehicle

is brought to a stop after heavy use

(engine still running).

3. A normal condition. No correction

is necessary. Gauge reading should

return to normal range after vehicle

is driven.

4. Gauge reading high after

restarting a warmed-up (hot)

engine.

4. A normal condition. No correction

is necessary. The gauge should

return to normal range after a few

minutes of engine operation.

5. Coolant level low (air will build

up in the cooling system causing

the thermostat to open late).

5. Check and correct coolant leaks.

Refer to Testing Cooling System for

Leaks in this section.

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing thermostat

to open late.

6. (a) Check for cylinder head

gasket leaks with a commercially

available block leak tester. Repair

as necessary.

(b) Check for coolant in engine oil.

Inspect for white steam emitting

from exhaust system. Repair as

necessary.

7. Water pump impeller loose on

shaft.

7. Check water pump and replace

as necessary. Refer to Water Pump

Removal in this section.

8. Air leak on the suction side of

water pump allows air to build up in

cooling system causing thermostat

to open late.

8. Locate leak and repair as

necessary.

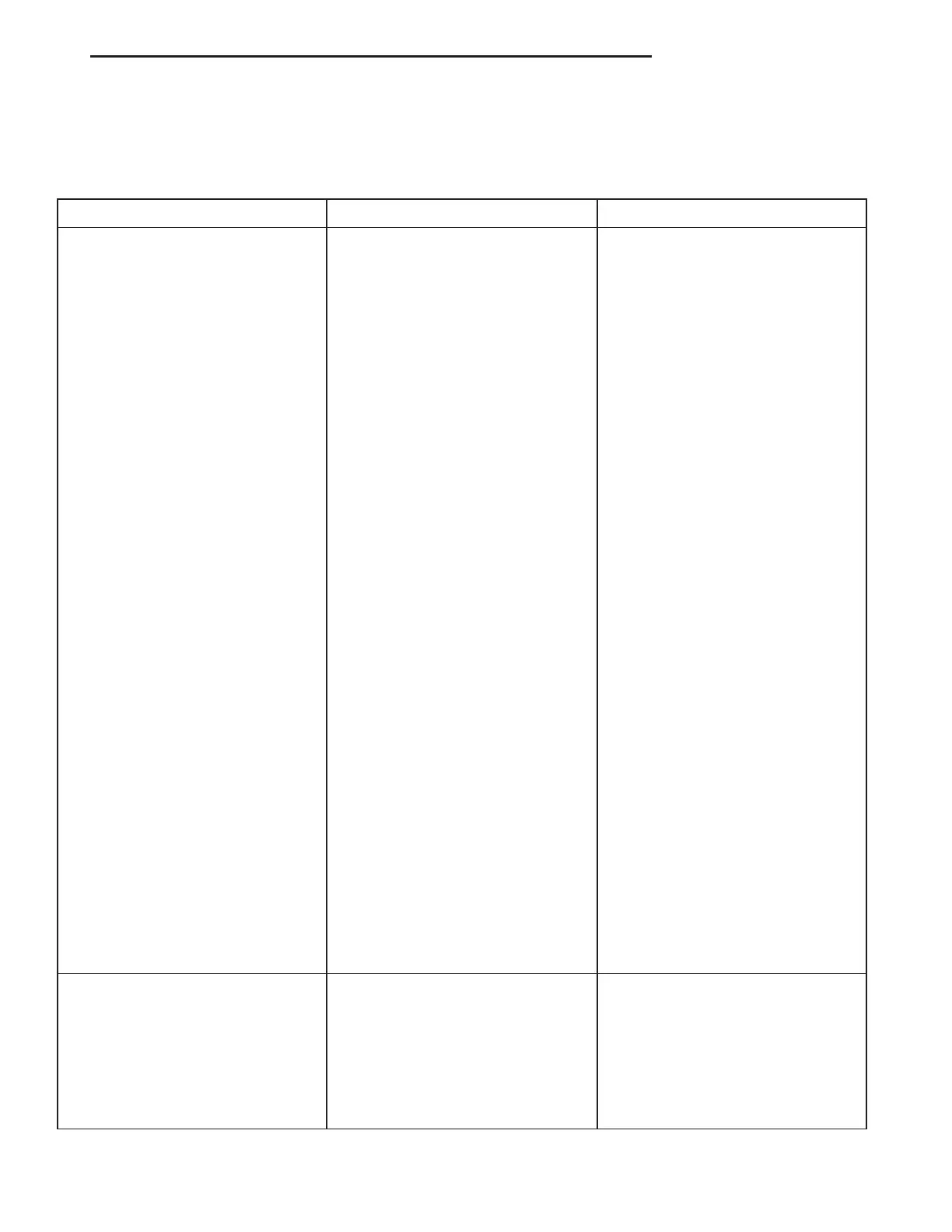

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.

1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.

1. Check condition of radiator cap

and cap seal. Refer to Pressure

Cap in this group. Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Make sure a 50% by volume

mixture of coolant is used.

LH COOLING SYSTEM 7 - 11

Loading...

Loading...