(8) Install downstream oxygen sensor and connect

electrical connector.

(9) Install SRV (Single Runner Valve) vacuum res-

ervoir and control valve assembly at right rear of

engine (3.2/3.5L engine only).

(10) Install air cleaner assembly with air inlet

hose.

(11) Raise vehicle on hoist.

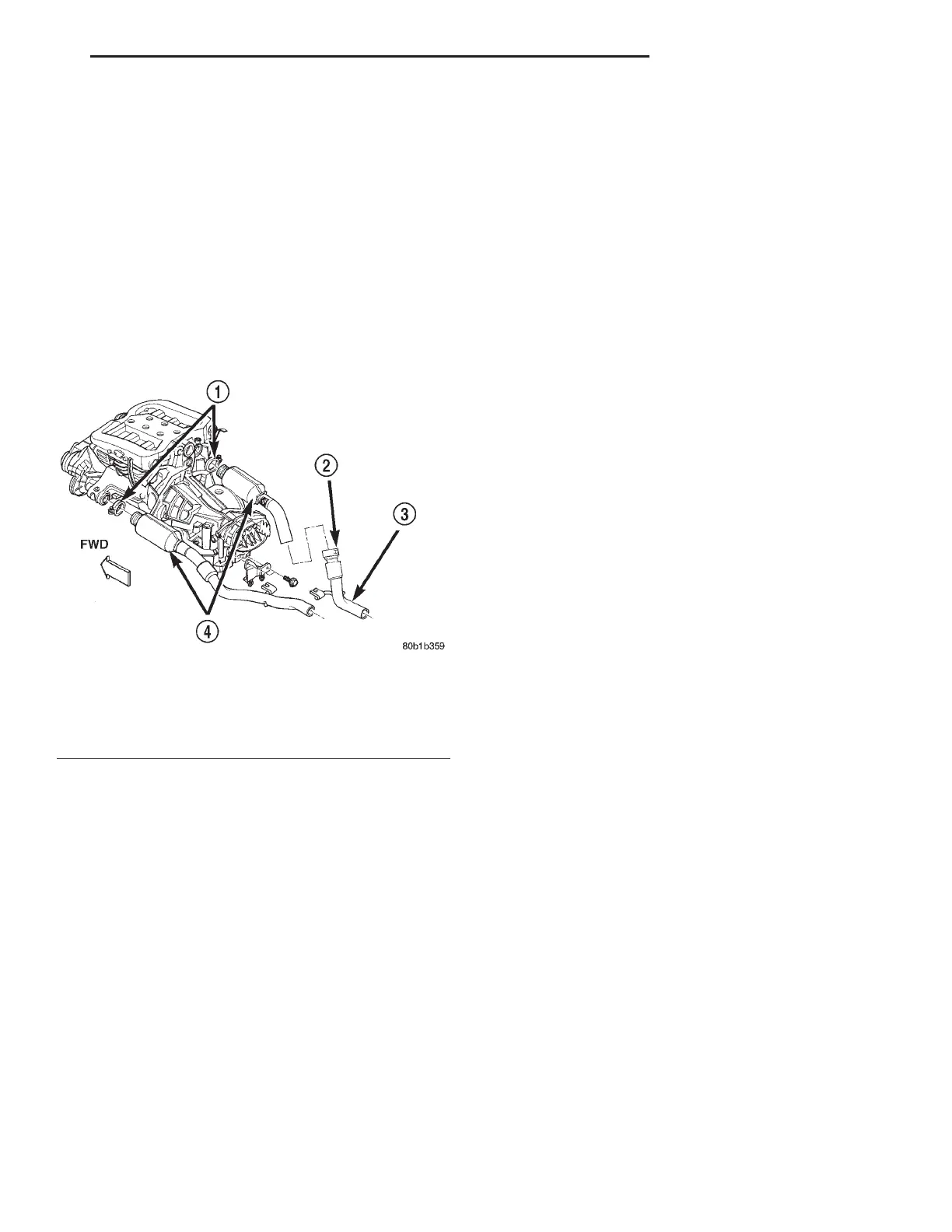

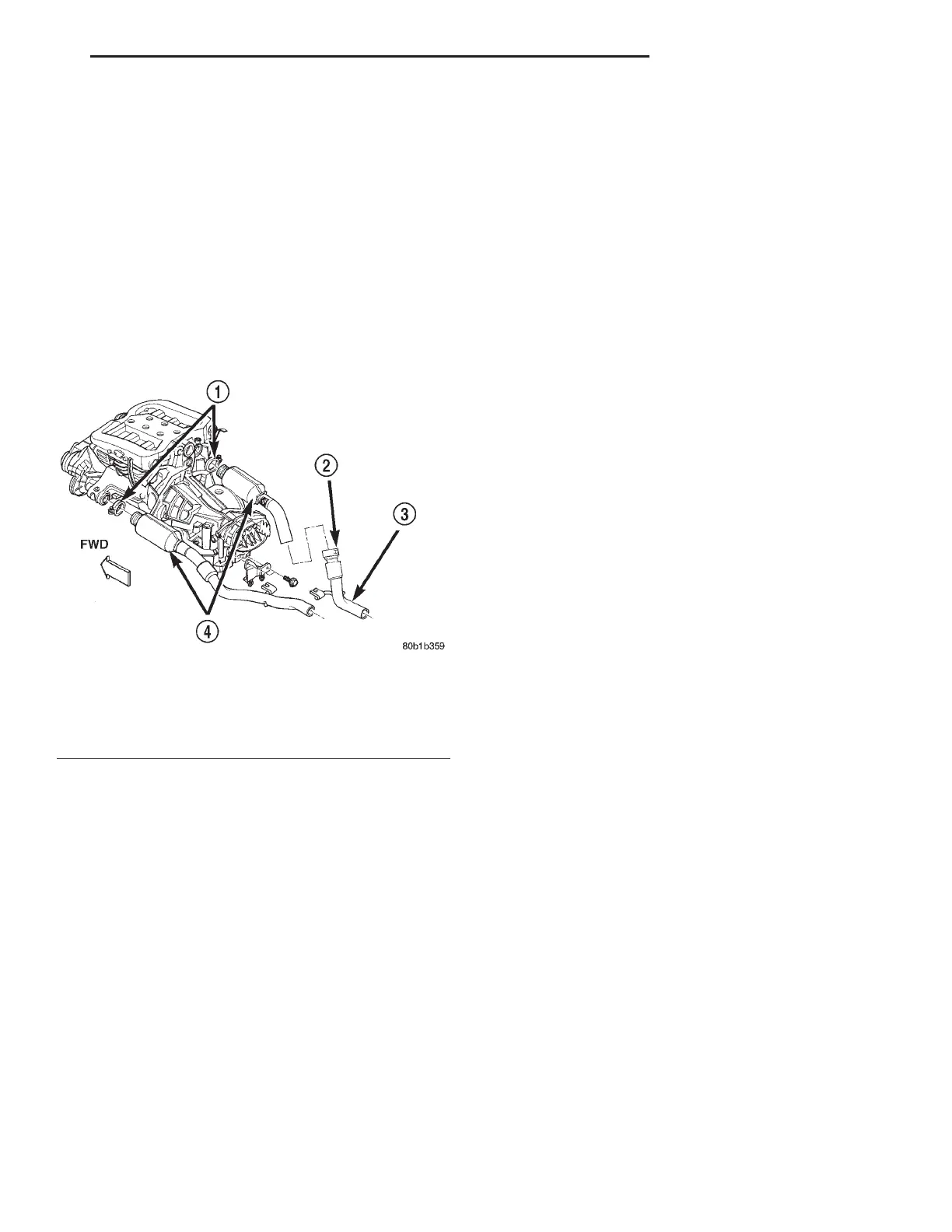

(12) Tighten extension pipe band clamp to 61 N·m

(45 ft. lbs.) (Fig. 7).

(13) Install and/or tighten nut attaching extension

pipe to transaxle bracket to 47 N·m (35 ft. lbs.).

(14) Install exhaust system.

(15) Lower vehicle.

LEFT CATALYTIC CONVERTER

REMOVAL

(1) Loosen and remove V-Band clamp at exhaust

manifold joint (Fig. 7).

NOTE: Do not reuse V-Band clamp.

(2) Hoist vehicle.

(3) Remove exhaust system. Refer to procedure in

this section.

(4) Disconnect downstream oxygen sensor electri-

cal connector and remove sensor from converter pipe.

(5) Loosen or remove nut attaching left pipe to

transaxle bracket (Fig. 7).

CAUTION: Care should be taken when removing

converter not to damage driveshaft boot.

(6) Remove converter from below vehicle.

INSTALLATION

(1) Install converter.

(2) Attach a NEW V-Band clamp and tighten to 11

N·m (100 in. lbs.) (Fig. 7).

(3) Install and/or tighten nut attaching pipe to

transaxle bracket to 47 N·m (35 ft. lbs.) (Fig. 7).

(4) Install downstream oxygen sensor and connect

electrical connector.

(5) Install exhaust system.

(6) Lower vehicle.

CLEANING AND INSPECTION

EXHAUST SYSTEM

INSPECTION

Inspect the exhaust pipes, catalytic converters,

muffler, and resonators for cracked joints, broken

welds and corrosion damage that would result in a

leaking exhaust system. Inspect the clamps, support

brackets, and insulators for cracks and corrosion

damage.

NOTE: Slip joint band clamps are spot welded to

exhaust system. If a band clamp must be replaced,

the spot weld must be ground off.

ADJUSTMENTS

EXHAUST SYSTEM ALIGNMENT

A misaligned exhaust system is usually indicated

by a vibration, rattling noise, or binding of exhaust

system components. These noises are sometimes hard

to distinguish from other chassis noises. Inspect

exhaust system for broken or loose clamps, heat

shields, isolators, and brackets. Replace or tighten as

necessary. It is important that exhaust system clear-

ances and alignment be maintained.

Perform the following procedures to align the

exhaust system:

(1) Loosen clamps and support brackets.

(2) Align the exhaust system starting at the front,

working rearward.

(3) Tighten all clamps and brackets once align-

ment and clearances are achieved.

Fig. 7 Catalytic Converters

1 – V-BAND CLAMPS

2 – BAND CLAMP

3 – EXTENSION PIPE

4 – CATALYTIC CONVERTERS

LH EXHAUST SYSTEM 11 - 7

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...