(3) Install three gearbox screws and one tie down

bracket screw, if applicable. Tighten to 5.6 to 8 N·m

(50 to 70 in. lbs.) torque.

(4) Install regulator, using the switch, test opera-

tion of motor.

WINDOW SWITCHES

MASTER SWITCH

REMOVAL

INTREPID AND CONCORDE

(1) Open hood and disconnect the negative battery

cable remote terminal from the remote battery post

(Fig. 4).

(2) Remove driver’s door trim panel. Refer to

Group 23-Body, Front Door Trim Removal and Instal-

lation.

(3) Remove three mounting screws.

(4) Remove switch and disconnect wire connector.

LHS and 300M

(5) Open hood and disconnect the negative battery

cable remote terminal from the remote battery post

(Fig. 4).

(6) Using a trim stick (special tool #C-4755) or

equivalent, gently pry up on switch trim bezel and

lift up and out of trim panel.

(7) Disconnect wire connector from rear of switch

and remove switch from vehicle.

INSTALLATION

For installation, reverse the above procedures.

PASSENGER SWITCH

REMOVAL

(1) Open hood and disconnect the negative battery

cable remote terminal from the remote battery post

(Fig. 4).

(2) Remove passenger door trim panel. Refer to

Group 23-Body, Front Door Trim Removal and Instal-

lation.

(3) Disconnect switch wire connector.

(4) Remove switch from bezel and vehicle.

INSTALLATION

For installation, reverse the above procedures.

REAR DOOR SWITCHES

REMOVAL

(1) Open hood and disconnect the negative battery

cable remote terminal from the remote battery post

(Fig. 4).

(2) Open rear door.

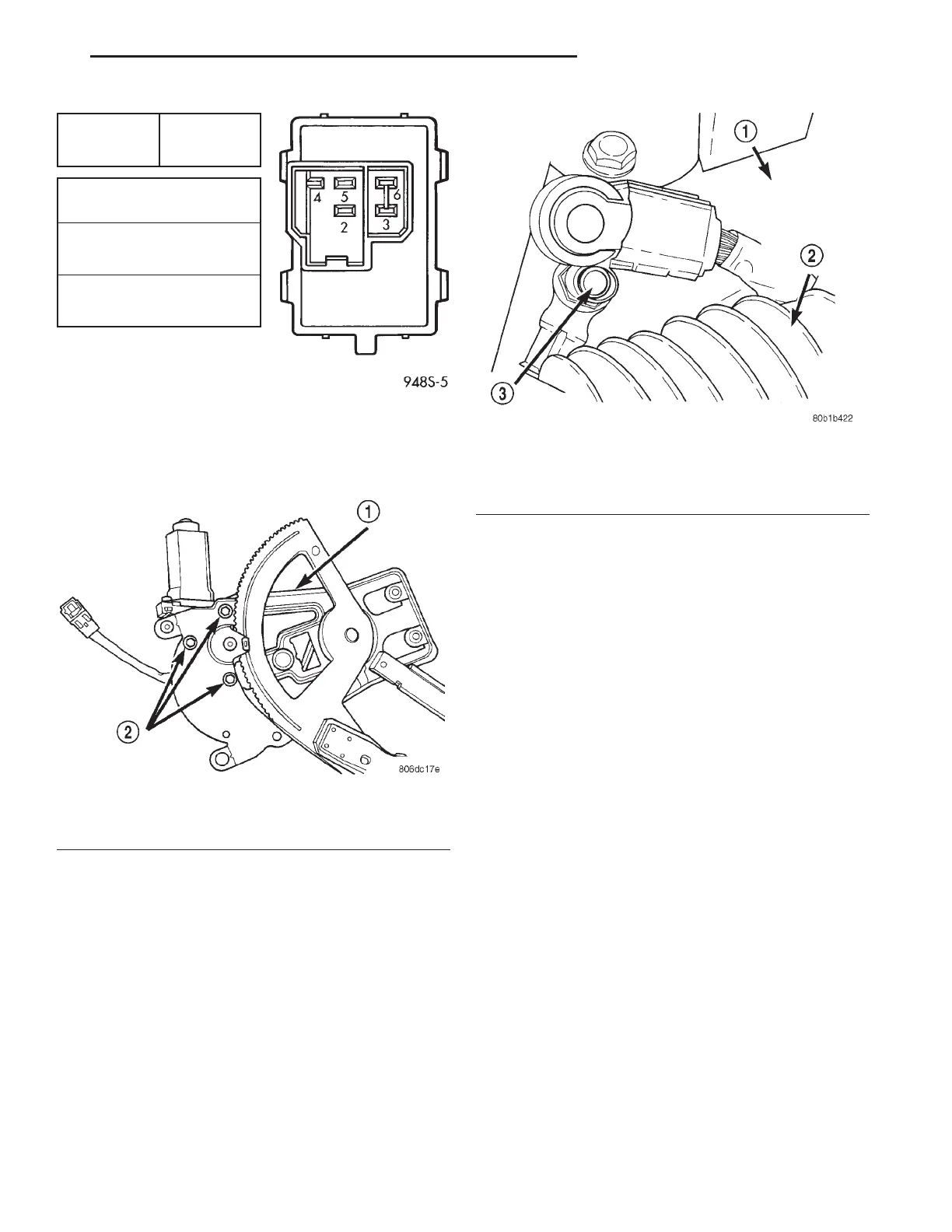

SWITCH

POSITION

CONTINUITY

BETWEEN

TERMINALS

OFF8 PIN2to5

PIN6to3

UP PIN6to3

PIN4to5

DOWN PIN 2 to 5

PIN4to3

Fig. 2 Passenger Window Switch

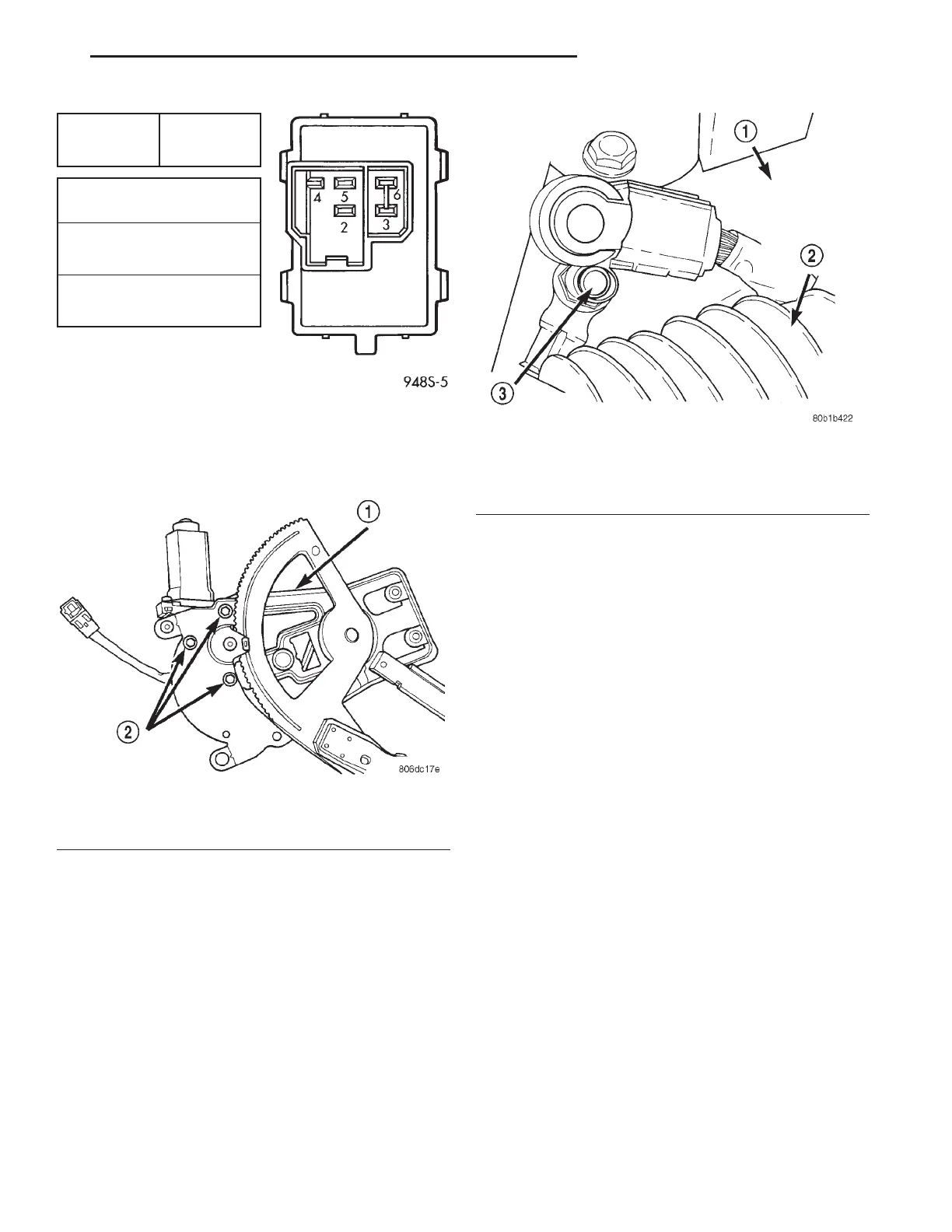

Fig. 3 Motor Removal

1 – CLAMP REGULATOR TO SECTOR GEAR

2 – MOTOR MOUNTING SCREWS

Fig. 4 Negative Battery Cable Remote Terminal

1 – RIGHT STRUT TOWER

2 – AIR CLEANER INLET TUBE

3 – REMOTE TERMINAL

LH POWER WINDOW SYSTEMS 8S - 3

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...