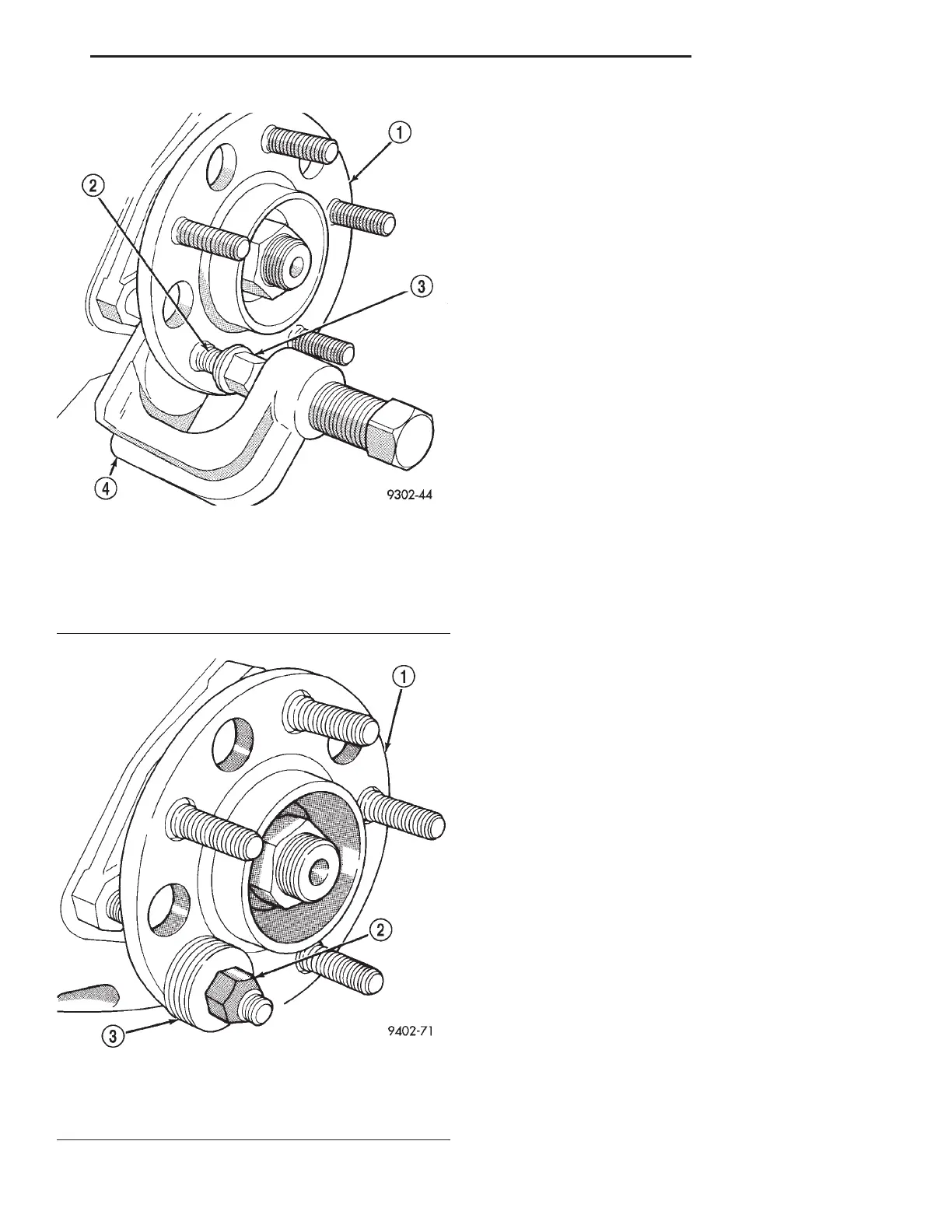

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the rotor on the hub and bearing assem-

bly (Fig. 59).

(4) Install front brake caliper back over braking

disc and align with caliper mounting holes on steer-

ing knuckle. Refer to Disc Brake Caliper in the

Removal And Installation Section in the Brake Group

of this service manual for the caliper installation pro-

cedure. Install the caliper to steering knuckle guide

pin bolts (Fig. 58) and tighten to a torque of 19 N·m

(168 in. lbs.).

(5) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N·m (95 ft. lbs.).

(6) Lower the vehicle to the ground.

DISASSEMBLY AND ASSEMBLY

STRUT ASSEMBLY (FRONT)

The Strut assembly must be removed from the

vehicle for it to be disassembled and assembled.

Refer to REMOVAL AND INSTALLATION in this

section for the required procedure.

For the disassembly and assembly of the strut

assembly, use strut spring compressor, Pentastar Ser-

vice Equipment (PSE) tool W-7200, or the equivalent,

to compress the coil spring. Follow the manufactur-

er’s instructions closely.

DISASSEMBLY

(1) If both struts are being serviced at the same

time, mark the coil spring and strut assembly accord-

ing to which side of the vehicle the strut was

removed from, and which strut the coil spring was

removed from.

(2) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions (Fig. 62). The strut clevis bracket should

be positioned outward. It will be necessary to turn

the strut assembly so the steering arm will clear the

compressor arm. Position the upper and lower hooks

on the coil spring, then place a clamp on the lower

end of the coil spring, so the strut is held in place

once the strut shaft nut is removed (Fig. 62).

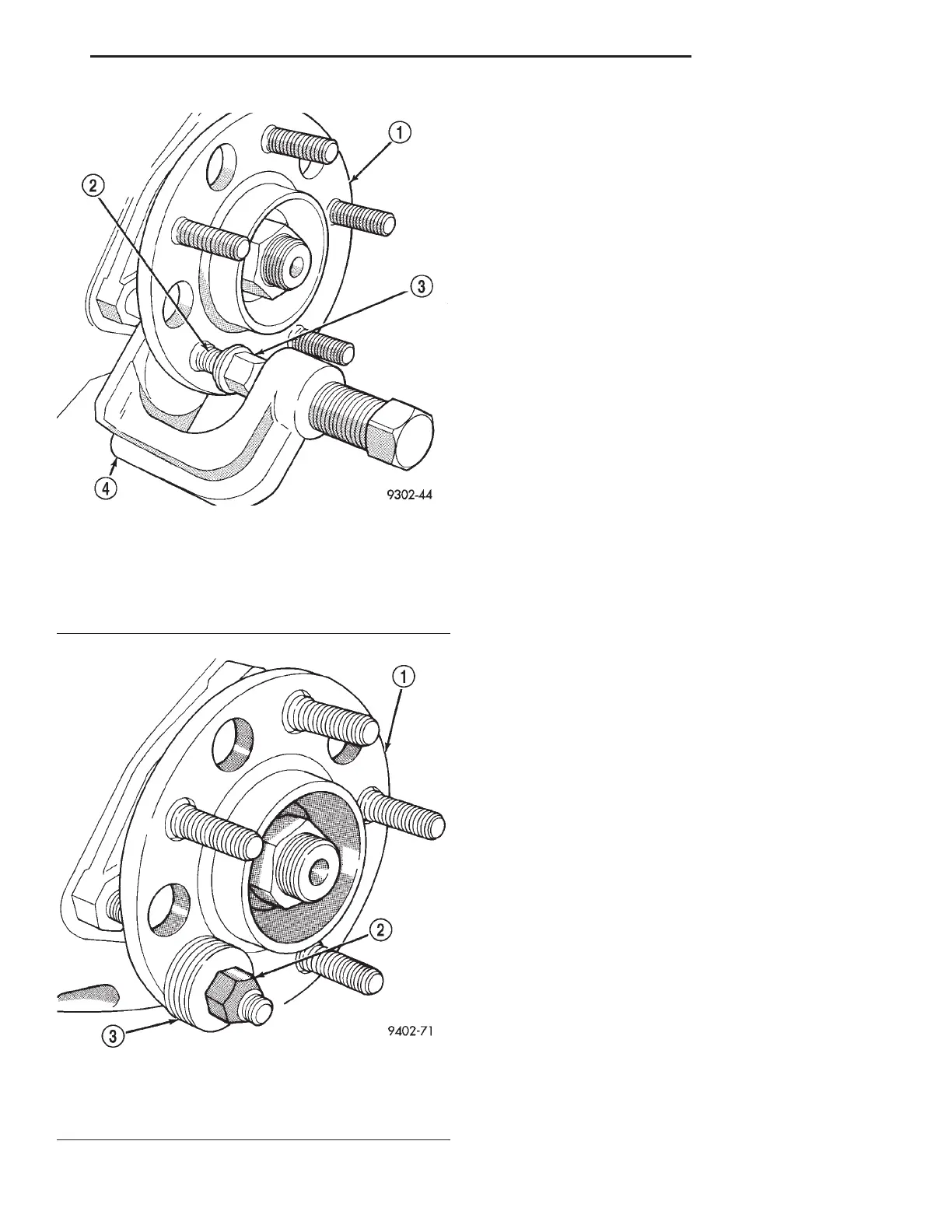

Fig. 60 Removing Wheel Stud From Hub And

Bearing

1 – HUB/BEARING ASSEMBLY

2 – WHEEL STUD

3 – LUG NUT

4 – SPECIAL TOOL C-4150

Fig. 61 Installing Wheel Stud Into Hub And Bearing

1 – HUB/BEARING ASSEMBLY

2 – WHEEL LUG NUT

3 – WASHERS

LH SUSPENSION 2 - 33

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...