OPERATION

The PCM operates the Automatic Shut Down

(ASD) relay and fuel pump relay through one ground

path. The PCM operates them by switching the

ground path for the relays on and off. Both relays

turn on and off at the same time.

The ASD relay connects battery voltage to the fuel

injectors and ignition coil. The fuel pump relay con-

nects battery voltage to the fuel pump.

The PCM turns the ground path off when the igni-

tion switch is in the Off position. Both relays are off.

When the ignition switch is in the On or Crank posi-

tion, the PCM monitors the crankshaft position sen-

sor and camshaft position sensor signals to

determine engine speed. If the PCM does not receive

a crankshaft position sensor signal and camshaft

position sensor signal when the ignition switch is in

the Run position, it de-energizes both relays. When

the relays are de-energized, battery voltage is not

supplied to the fuel injectors, ignition coil and fuel

pump.

PROPORTIONAL PURGE SOLENOID—PCM

OUTPUT

DESCRIPTION

All vehicles use a proportional purge solenoid. The

solenoid regulates the rate of vapor flow from the

EVAP canister to the throttle body. The PCM oper-

ates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

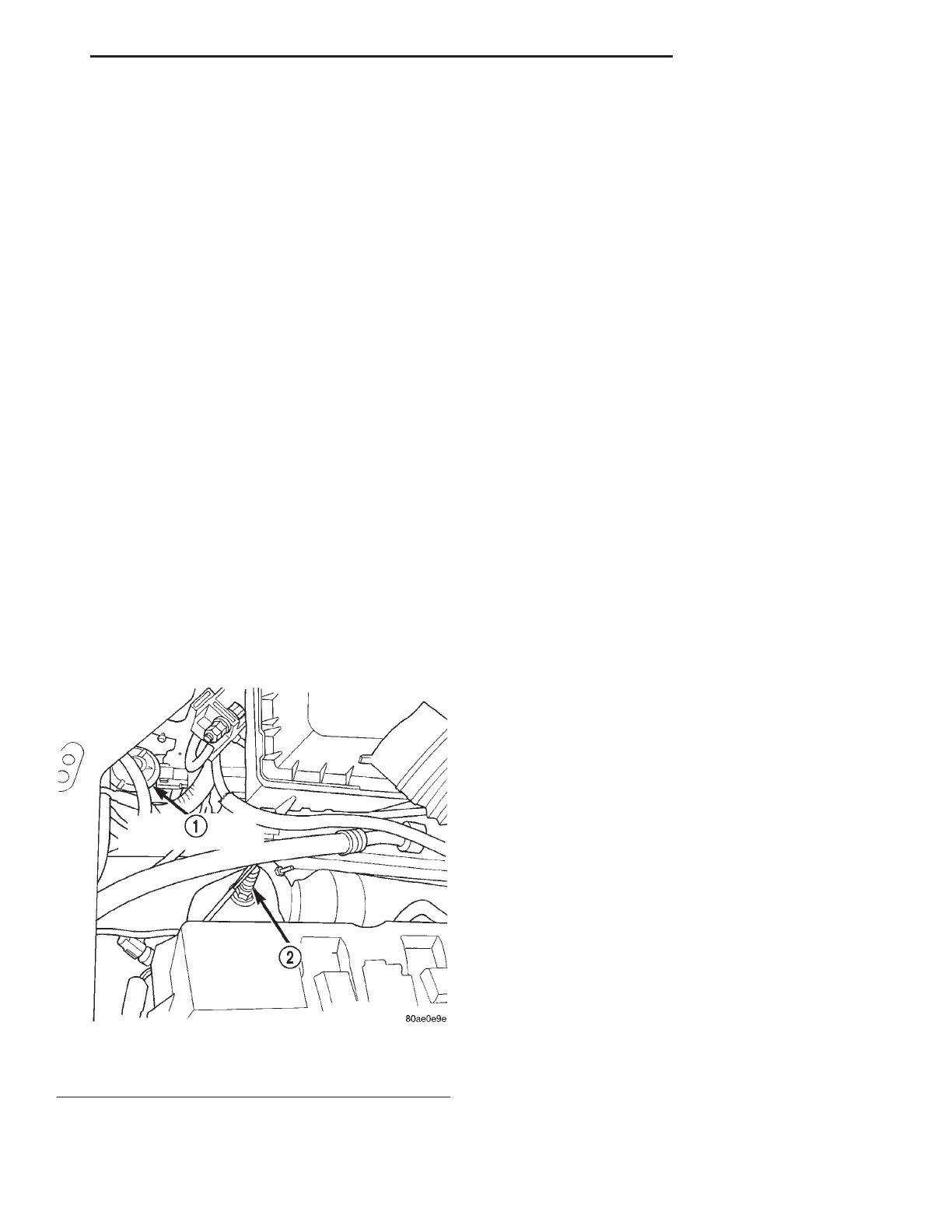

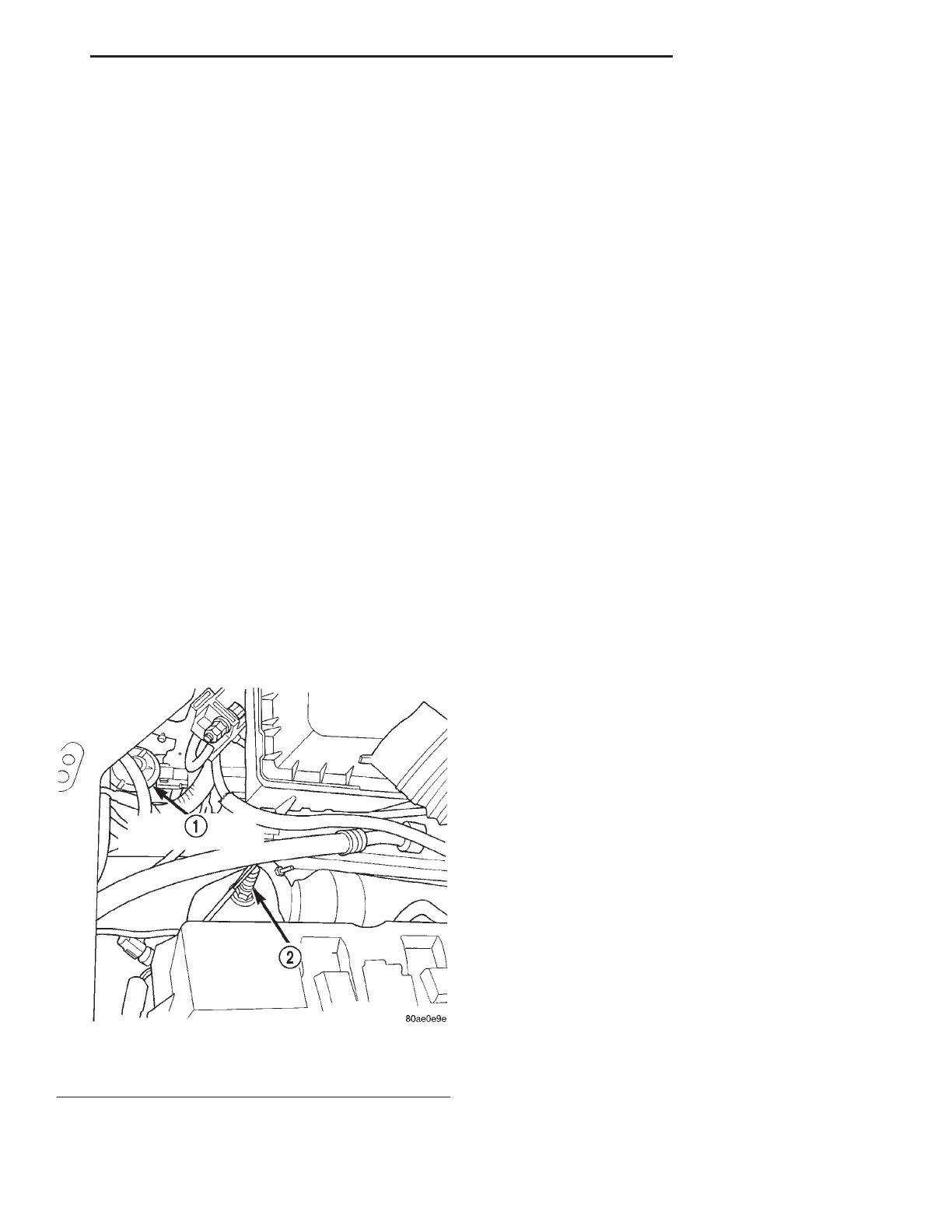

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid (Fig. 11) and then

adjusts that current to achieve the desired purge

flow. The proportional purge solenoid controls the

purge rate of fuel vapors from the vapor canister and

fuel tank to the engine intake manifold.

EXHAUST GAS RECIRCULATION (LSEGR)

DESCRIPTION

The EGR valve consists of three major components.

First there is the pintle, valve seat, and housing

which contains and regulates the gas flow. Second

there is the armature, return spring, and solenoid

coil to provide the operating force to regulate the

flow by changing the pintle position. The solenoid coil

assembly is in parallel with a diode and connects to

the two connectors in the connector assembly. The

third major component which senses pintle position

and is connected to the three connectors in the elec-

trical connector.

OPERATION

The exhaust gas recirculation flow is determined

by the engine controller. For a given set of conditions,

the engine controller knows the ideal exhaust gas

recirculation flow to optimize NOx and fuel economy

as a function of the pintle position. Pintle position is

obtained from the position sensor. The engine con-

troller adjusts the duty cycle of 128 Hz power sup-

plied to the solenoid coil to obtain the correct

position.

MANIFOLD TUNING VALVE (MTV)—PCM

OUTPUT

DESCRIPTION

The valve opens a crossover passage in that con-

nects both sides of the intake manifold plenum (Fig.

12). It is an elecrtic motor.

OPERATION

The PCM controls the MTV solenoid. The manifold

tuning valve optimizes acoustical tuning of the

intake system during wide open throttle operation

throughout the RPM range.

Fig. 11 Proportional Purge Solenoid

1 – PROPORTIONAL PURGE SOLENOID

2 – O2 SENSOR

LH FUEL SYSTEM 14 - 33

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...