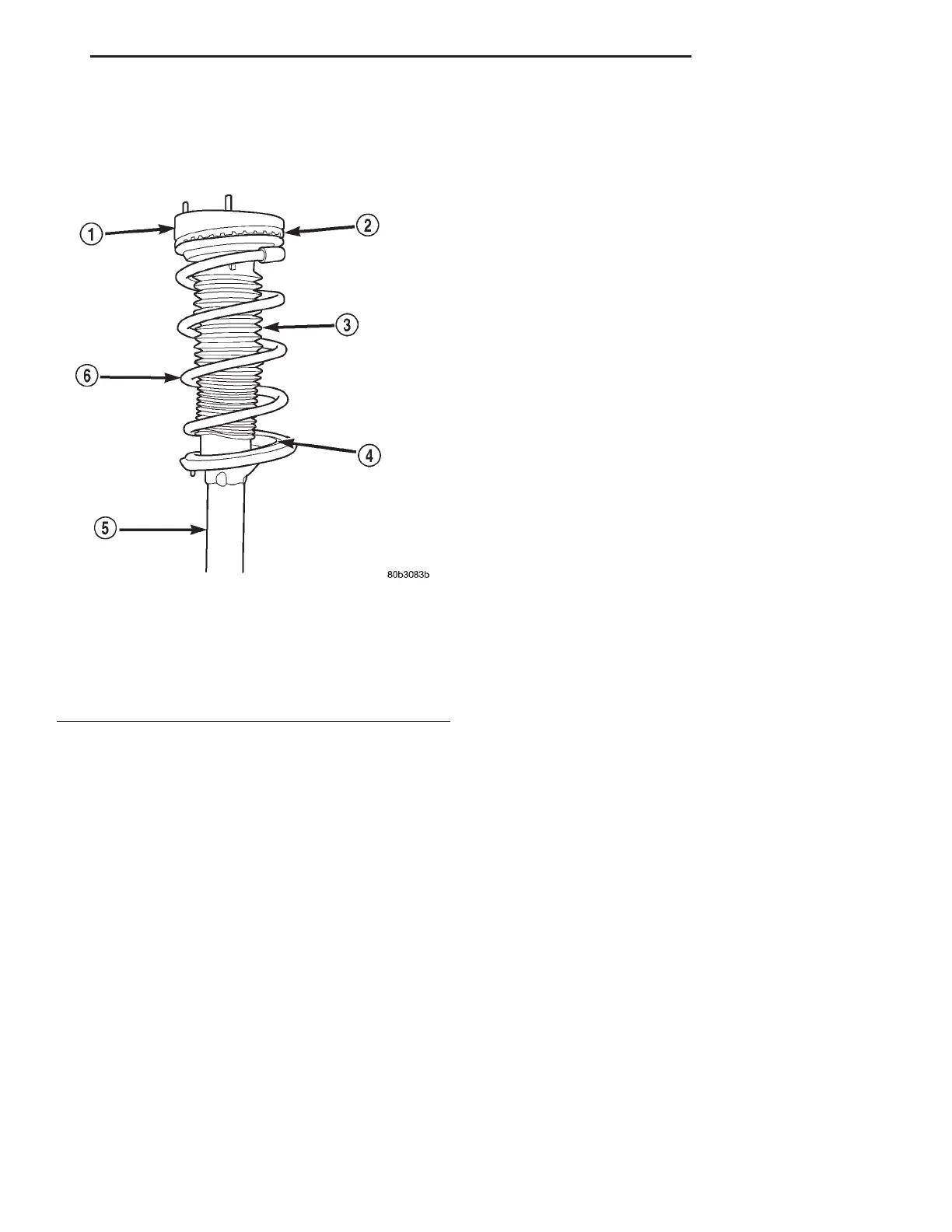

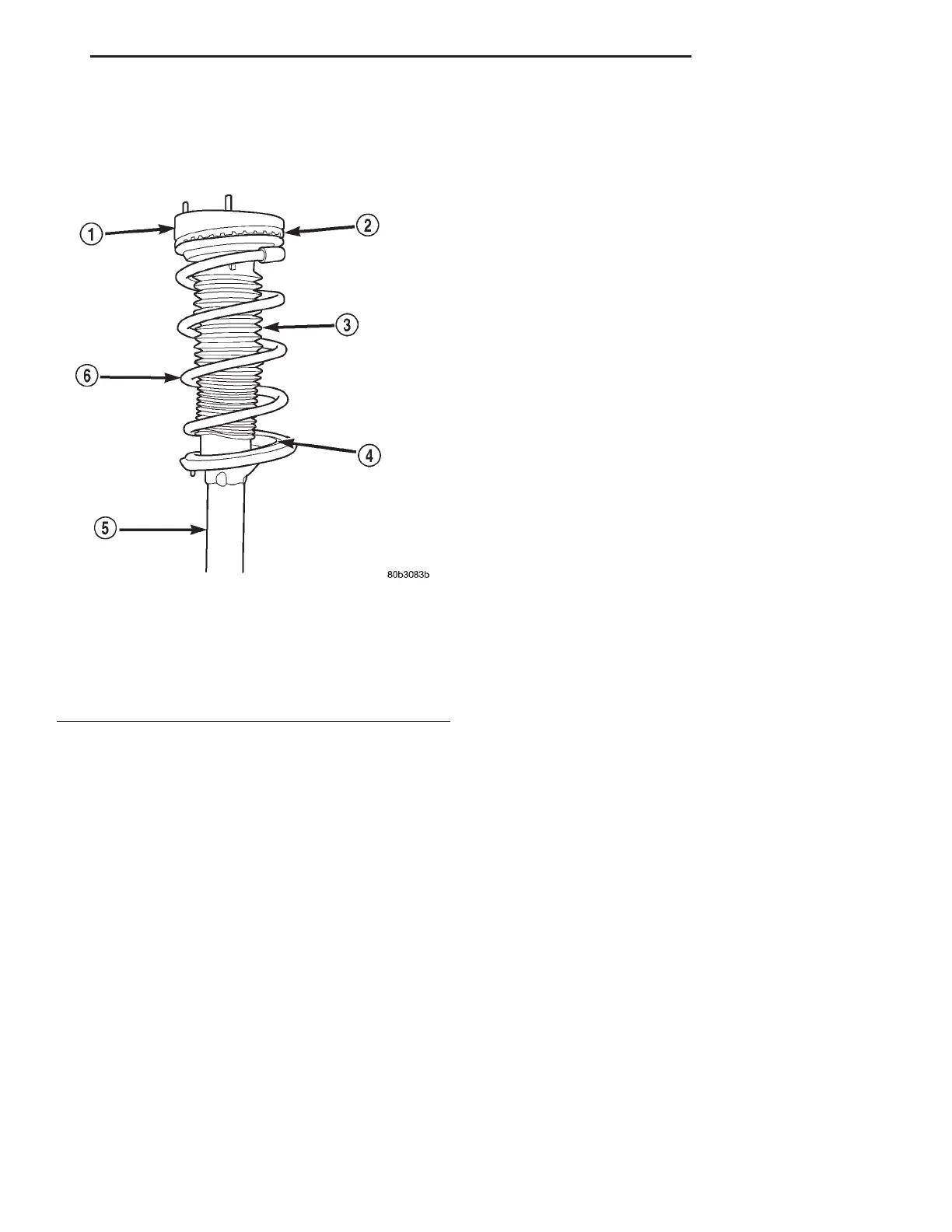

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 3).

(3) Inspect for damaged upper and lower spring

isolators (Fig. 3).

(4) Lift dust boot and inspect strut assembly for

evidence of fluid running from the upper end of fluid

reservoir. (Actual leakage will be a stream of fluid

running down the side and dripping off lower end of

unit). A slight amount of seepage between the strut

rod and strut shaft seal is not unusual and does not

affect performance of the strut assembly. Also inspect

jounce bumpers inside dust boot for signs of damage

or deterioration.

(5) Verify correct struts and coil springs are

installed on vehicle.

Coil springs are rated separately for each side of

vehicle depending on optional equipment and type of

service.

NOTE: If the coils springs require replacement, be

sure that the springs being replaced, are replaced

with springs meeting the correct load and spring

rate for the vehicle.

Replacement of the coil spring requires removal

and disassembly of the strut assembly. Refer to Strut

Assembly in the Removal and Installation section in

this group of the service manual for the required

removal and replacement procedure. Then, refer to

Strut Assembly in the Disassembly and Assembly

section in this group of the service manual for the

required procedure to disassemble and assemble the

shock absorber.

SPINDLE

The rear suspension spindle is not a repairable

component of the rear suspension, If it is determined

that the spindle is broken or bent when servicing the

vehicle, no attempt is to be made to repair or to

straighten the spindle. THE SPINDLE MUST BE

REPLACED IF FOUND TO BE DAMAGED IN

ANY WAY.

HUB AND BEARING (REAR)

The rear hub and bearing assembly is designed for

the life of the vehicle and should require no mainte-

nance. The following procedure may be used for eval-

uation of bearing condition.

With wheel and brake drum removed, rotate

flanged outer ring of hub. Excessive roughness, lat-

eral play or resistance to rotation may indicate dirt

intrusion or bearing failure. If the rear wheel bear-

ings exhibit these conditions during inspection, the

hub and bearing assembly should be replaced.

Damaged bearing seals and resulting excessive

grease loss may also require bearing replacement.

Moderate grease loss from bearing is considered nor-

mal and should not require replacement of the hub

and bearing assembly.

LATERAL LINKS

Inspect the lateral link isolator bushings and

sleeves for signs of damage or deterioration. If the

lateral link isolator bushings or sleeves are damaged

or are deteriorated, replacement of the lateral link

assembly will be required. The isolator bushings are

not serviceable as a separate component of the lat-

eral link assembly.

Inspect the lateral links for signs of contact with

the ground or road debris which has bent or caused

other damage to the lateral link assembly. If the lat-

eral link is bent or damaged, the lateral link will

require replacement. Do not attempt to repair or

straighten a lateral link.

TRAILING ARM

Inspect the trailing arm and trailing arm bushings

for signs of deterioration and or damage. If the trail-

ing arm bushings are deteriorated or the trailing arm

is damaged in any way, replacement of the trailing

arm will be required.

Inspect the trailing arm for signs of contact with

the ground or road debris which has bent or caused

Fig. 3 Strut Assembly Inspection

1 – UPPER STRUT MOUNT

2 – UPPER SPRING ISOLATOR

3 – DUST BOOT

4 – LOWER SPRING ISOLATOR

5 – STRUT ASSEMBLY

6 – COIL SPRING

LH SUSPENSION 2 - 47

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...