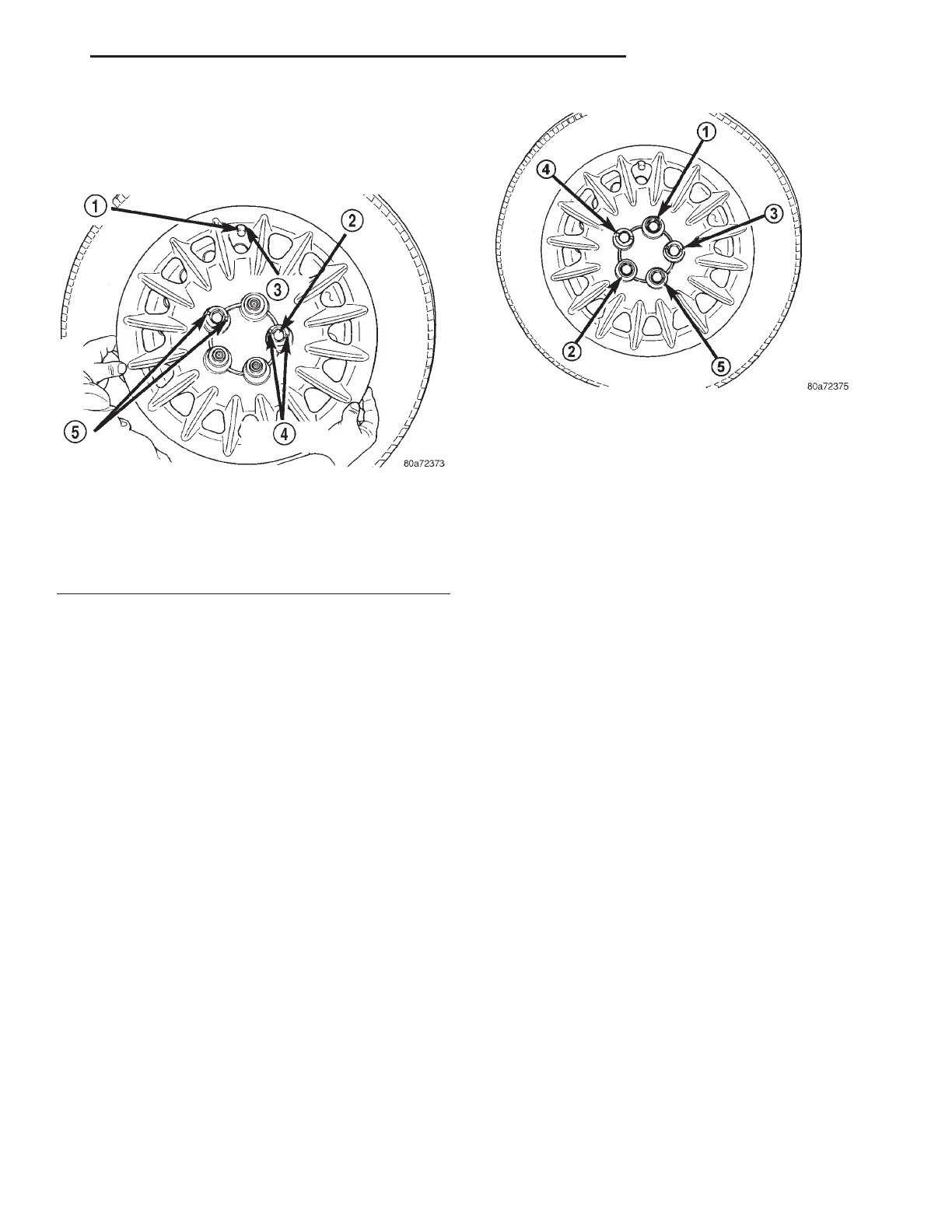

(2) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 20). Align the two

holes in the wheel cover having the retaining tabs,

with the two installed wheel nuts (Fig. 20).

(3) Press in on center of wheel cover until retain-

ing tabs on wheel cover engage with wheel nuts. This

will hold the wheel cover to the wheel.

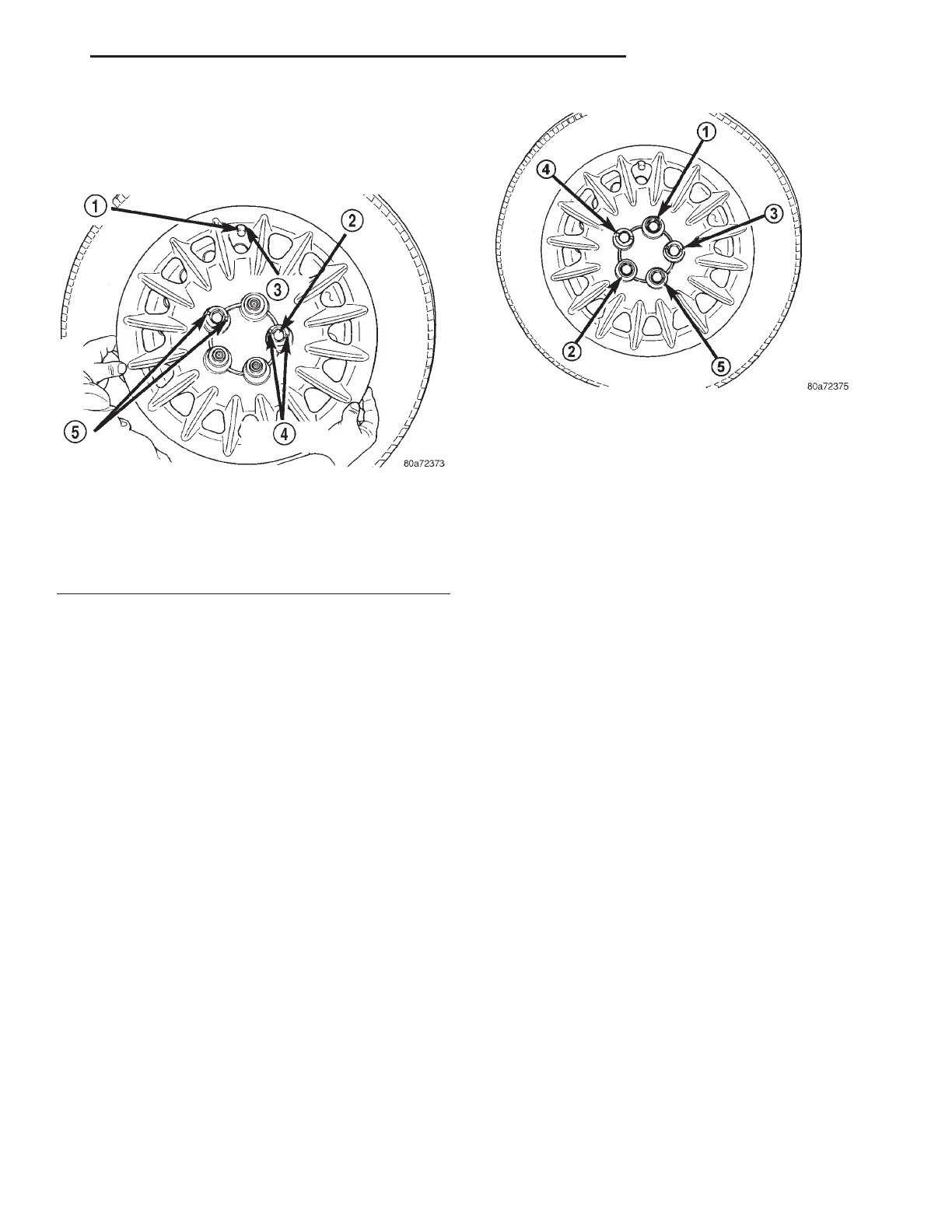

(4) Install the three remaining wheel nuts (Fig.

17).

(5) Progressively tighten the 5 wheel nuts in the

proper sequence (Fig. 21). Tighten wheel nuts to 135

N·m (100 ft. lbs.).

(6) Lower the vehicle.

CLEANING AND INSPECTION

ALUMINUM WHEEL CARE

Chrome plated and painted aluminum wheels

should be cleaned regularly using mild soap and

water to maintain their luster and to prevent corro-

sion.

Care must be taken in the selection of tire and

wheel cleaning chemicals and equipment to prevent

damage to the wheels. Any of the “DO NOT USE”

items listed below WILL damage chrome plated and

painted aluminum wheels.

DO NOT USE:

• any abrasive metal cleaner

• any abrasive cleaning pad or brush

• any cleaner that contains an acid (this will

immediately react with and discolor the chromium

surface)

• chrome polish (unless it is buffed off immedi-

ately after application)

• oven cleaner

• a car wash that uses carbide-tipped wheel clean-

ing brushes

SPECIFICATIONS

WHEEL SPECIFICATIONS

Wheel:

Mounting Stud Size.............. M12x1.5mm

Mounting Stud Lug Nut Hex Size ......... 19mm

Wheel Mounting (Lug)

Nut Tightening Torque . . . 135 N·m (100 ft. lbs.)

Fig. 20 Wheel Cover Installation Position

1 – VALVE STEM

2 – WHEEL NUT

3 – NOTCH

4 – RETAINING TABS

5 – RETAINING TABS

Fig. 21 Wheel Nut Tightening Sequence

LH TIRES AND WHEELS 22 - 15

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...