INSTALLATION

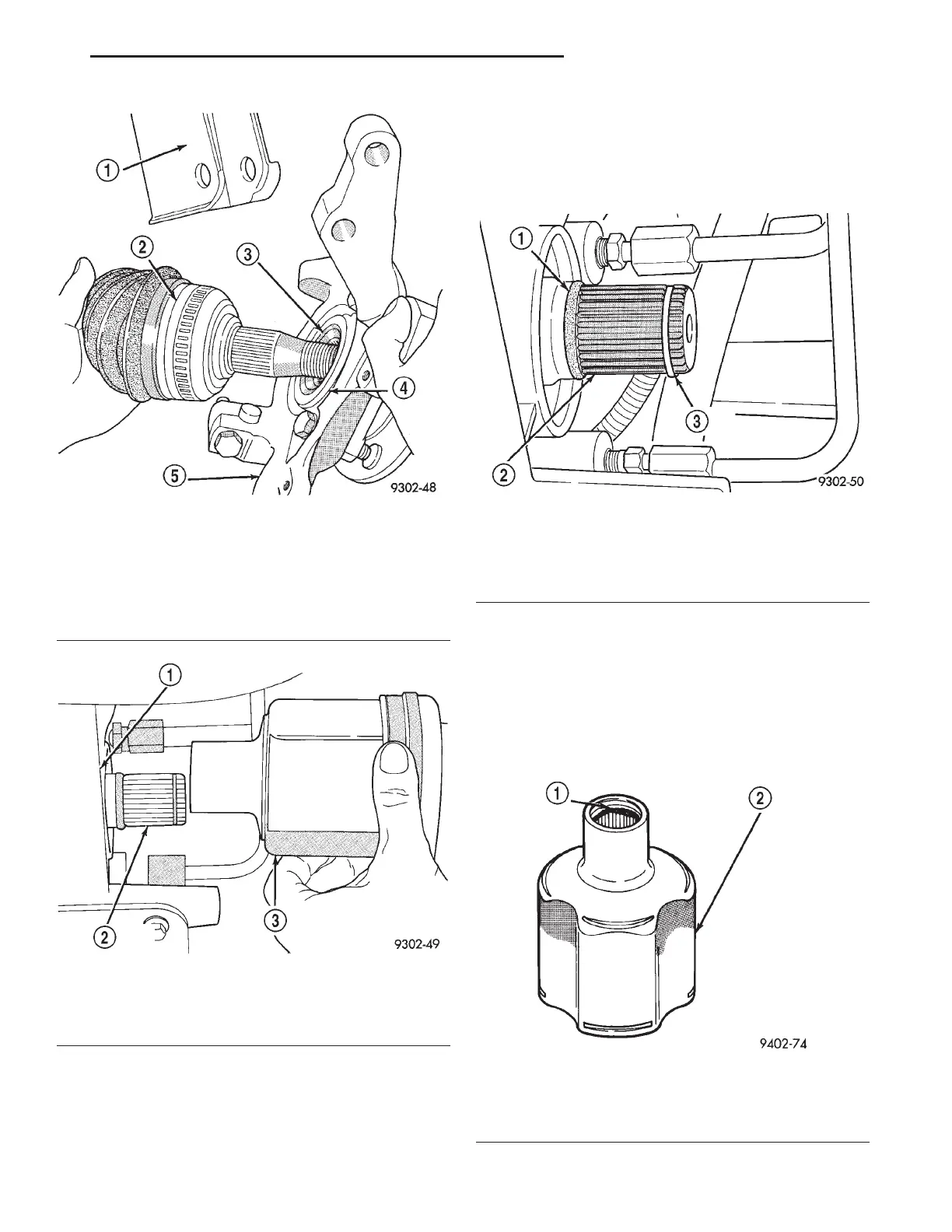

CAUTION: The inboard tripod joint retaining circlip

and O-ring seal (Fig. 13) on the transaxle stub shaft

are not re-usable. Whenever the inboard tripod joint

is removed from the stub shaft, the retaining circlip

and O-ring seal MUST BE REPLACED. The retaining

circlip and O-ring seal is included in all service kits

requiring removal of the inboard tripod joint from

the stub shaft.

(1) Replace O-ring seal and tripod joint retaining

circlip (Fig. 13) on the transaxle stub shaft.

(2) Evenly apply a bead of grease, such as Mopar

Multi-Purpose Lubricant or an equivalent, around

spline of inner tripod joint (Fig. 14) where the O-ring

seats against tripod joint. This will spread grease

onto stub shaft during tripod joint installation pre-

venting corrosion and help to seal the O-ring.

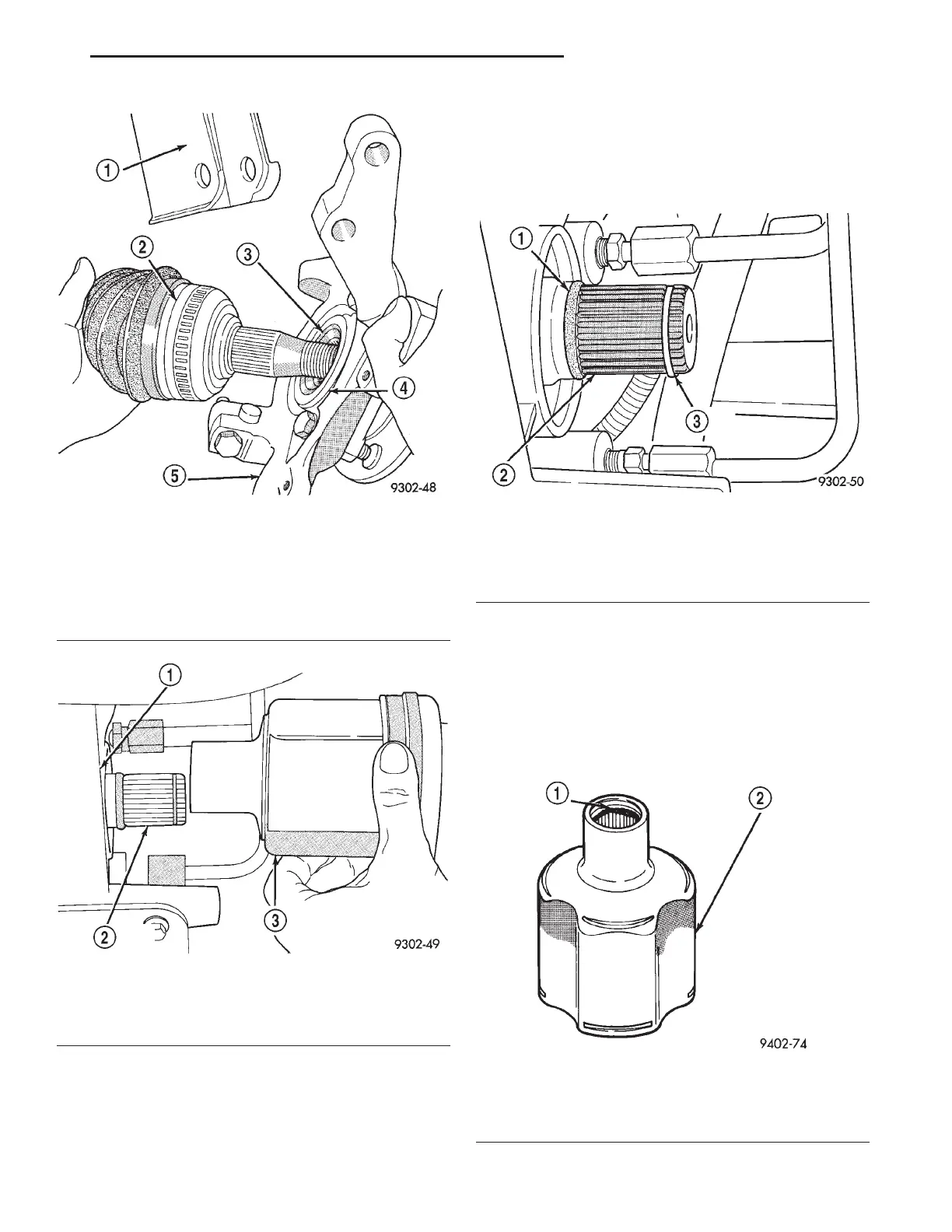

Fig. 11 Outer C/V Joint Removal From Hub and

Bearing

1 – STRUT ASSEMBLY

2 – OUTER C/V JOINT

3 – HUB/BEARING ASSEMBLY

4 – FLINGER DISK

5 – STEERING KNUCKLE

Fig. 12 Inner Tripod Joint Removal From Stub Shaft

1 – TRANSAXLE

2 – TRANSMISSION STUB SHAFT

3 – INNER TRIPOD JOINT

Fig. 13 Tripod Joint Retaining Circlip And O-Ring

Seal

1 – O-RING SEAL

2 – STUB SHAFT

3 – RETAINING CIR CLIP

Fig. 14 Grease Applied To Inner Tripod Joint

Housing Spline

1 – APPLY 1 MILLILITER BEAD OF GREASE HERE

2 – INNER TRIPOD JOINT HOUSING

LH DIFFERENTIAL AND DRIVELINE 3 - 7

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...