OPERATION

The CMP sensor contains a hall effect device called

a sync signal generator to generate a fuel sync sig-

nal. The camshaft position sensor helps provide cyl-

inder identification to the Powertrain Control Module

(PCM) (Fig. 10) or (Fig. 11). The sensor generates

pulses as groups of notches on the camshaft sprocket

pass underneath it. The PCM keeps track of crank-

shaft rotation and identifies each cylinder by the

pulses generated by the notches on the camshaft

sprocket. Crankshaft pulses follow each group of

camshaft pulses.

When metal aligns with the sensor, voltage goes

low (less than 0.3 volts). When a notch aligns with

the sensor, voltage spikes high (5.0 volts). As a group

of notches pass under the sensor, the voltage

switches from low (metal) to high (notch) then back

to low. The number of notches determine the amount

of pulses. If available, an oscilloscope can display the

square wave patterns of each timing event.

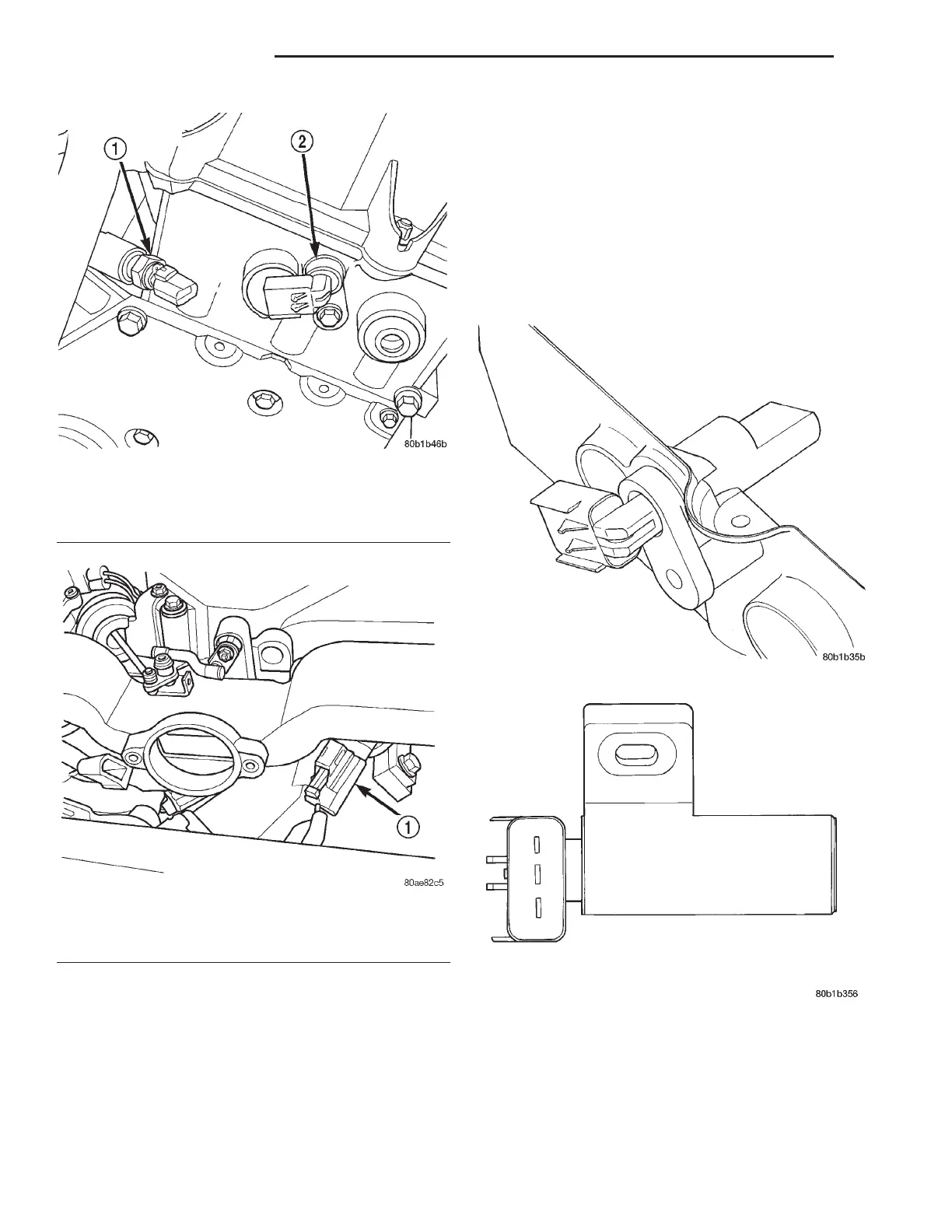

Fig. 8 Camshaft Position Sensor Location—2.7L

Engine

1 – ENGINE COOLANT TEMPERATURE SENSOR

2 – CAM SENSOR

Fig. 9 Camshaft Position Sensor Location—3.2/3.5L

Engine

1 – CAMSHAFT SENSOR

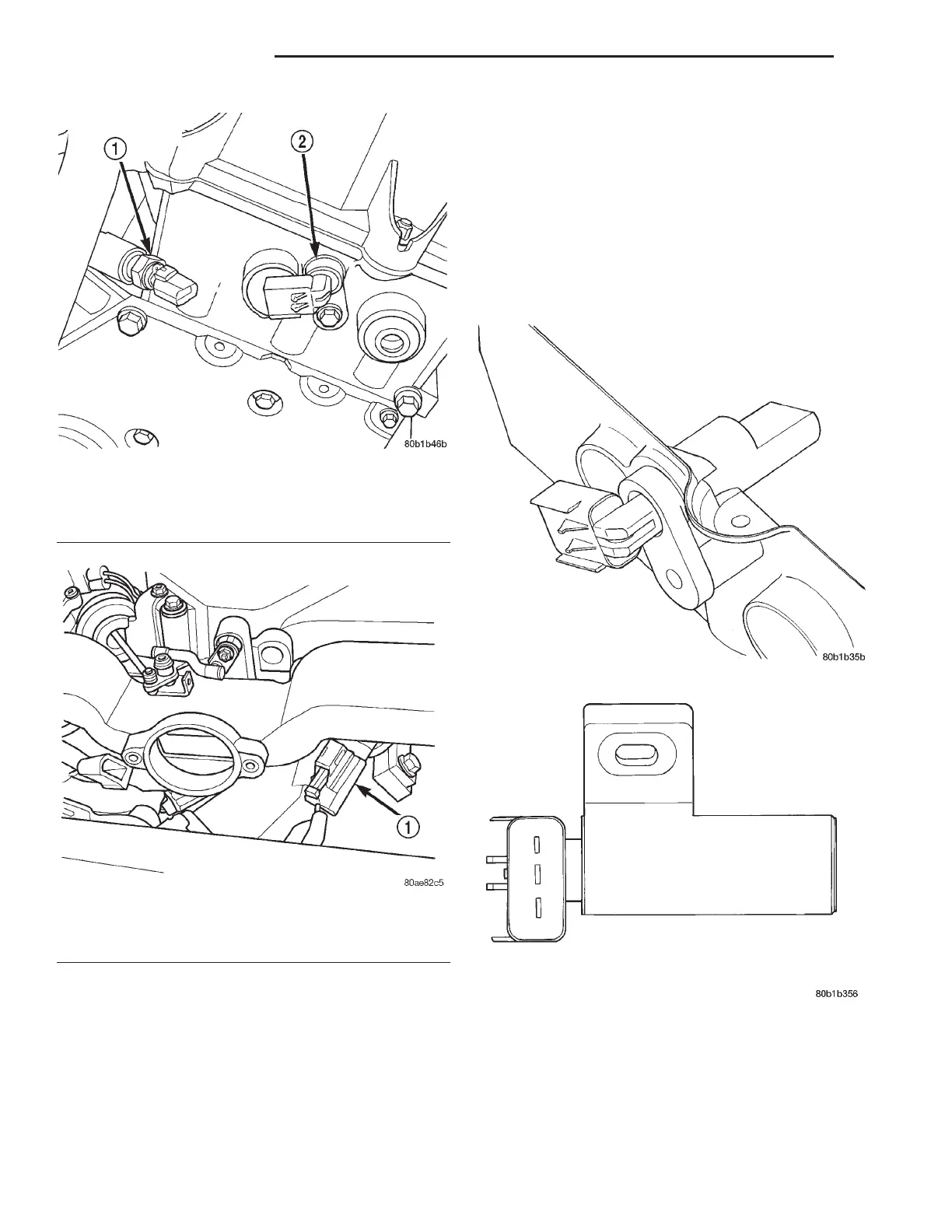

Fig. 10 Camshaft Position Sensor—2.7L Engine

Fig. 11 Camshaft Position Sensor—3.2/3.5L Engine

8D - 4 IGNITION SYSTEM LH

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...