INSTALLATION

CAUTION: If a burr or scratch is present on the

crankshaft edge (chamfer), clean surface using 400

grit sand paper to prevent seal damage during

installation.

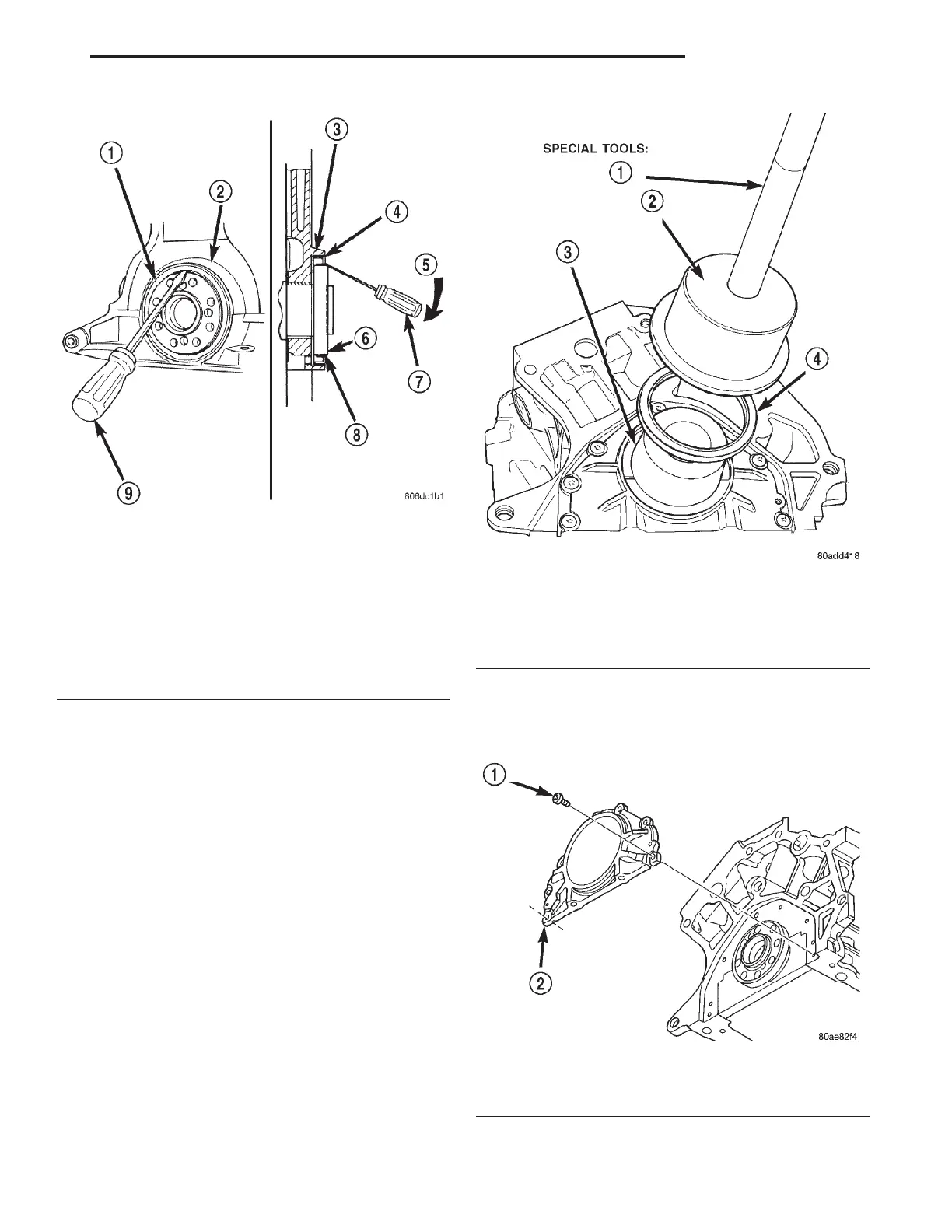

(1) Place Special Tool 6926-1 Guide on crankshaft

(Fig. 82). This is a pilot tool with a magnetic base.

(2) Position seal over pilot tool. Assure that lip of

seal is facing towards the crankshaft during installa-

tion. The pilot tool remains on crankshaft during seal

installation.

(3) Using Special Tool 6926-2 Installer, and C-4171

Handle (Fig. 82), drive seal into the retainer housing

until seal is flush with housing surface.

(4) Install drive plate and transaxle. Refer to

TRANSAXLE for procedures.

CRANKSHAFT OIL SEAL RETAINER—REAR

REMOVAL

(1) Remove crankshaft rear oil seal and oil pan.

Refer to procedures in this section.

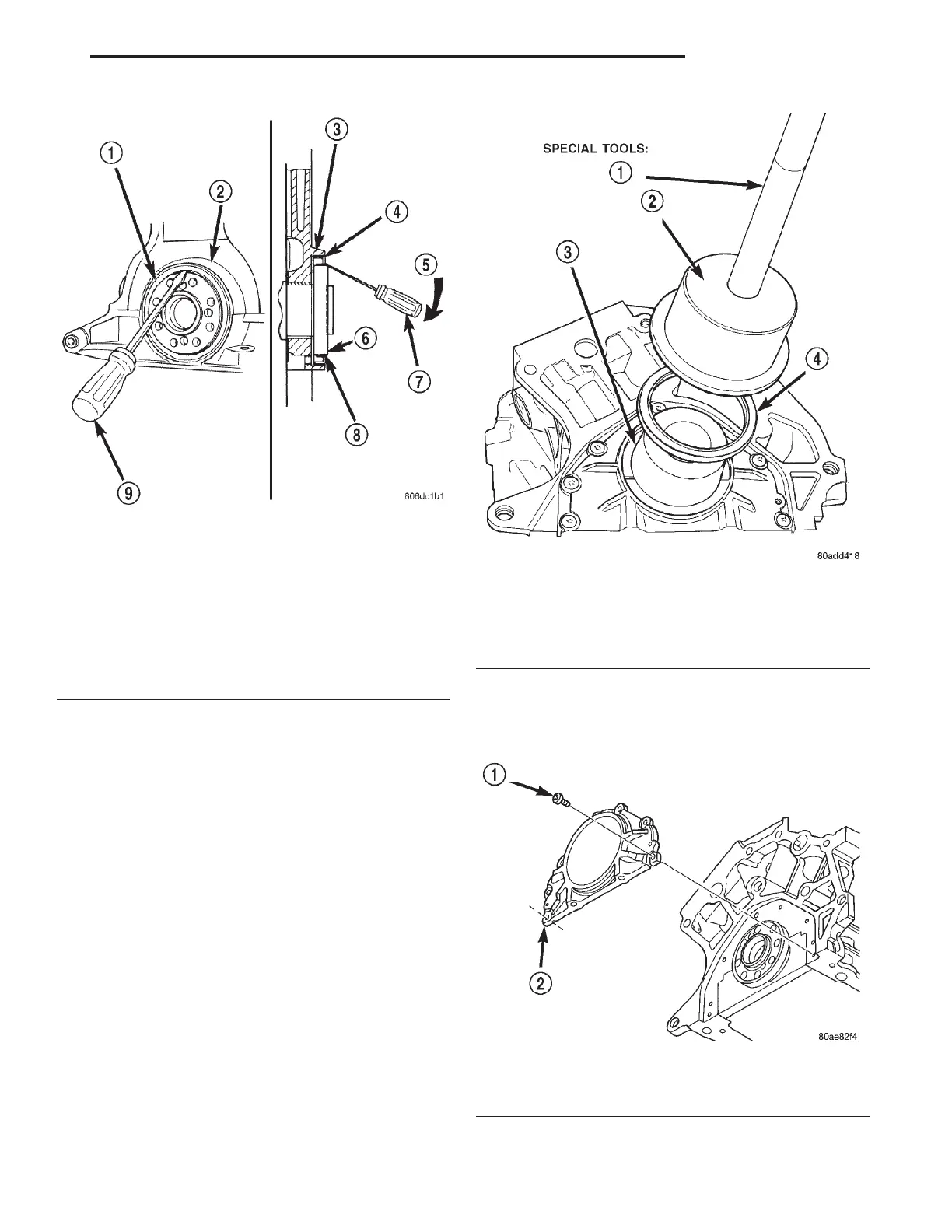

(2) Remove seal retainer attaching screws (Fig.

83).

(3) Remove retainer and gasket (Fig. 83).

Fig. 81 Rear Crankshaft Oil Seal Removal—Typical

1 – REAR CRANKSHAFT SEAL

2 – ENGINE BLOCK

3 – ENGINE BLOCK

4 – REAR CRANKSHAFT SEAL METAL CASE

5 – PRY IN THIS DIRECTION

6 – CRANKSHAFT

7 – SCREWDRIVER

8 – REAR CRANKSHAFT SEAL DUST LIP

9 – SCREWDRIVER

Fig. 82 Crankshaft Rear Seal—Installation

1 – C-4171 HANDLE

2 – 6926–2 INSTALLER

3 – 6926–1 GUIDE

4 – SEAL

Fig. 83 Oil Seal Retainer

1 – SCREWS (7)

2 – SEAL RETAINER

LH 2.7L ENGINE 9 - 53

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...