CAUTION: The collar must be tighten using the fol-

lowing procedure, as damage to the collar or oil

pan may occur.

(7) Install structural collar (Fig. 85) using the fol-

lowing tightening sequence:

(a) Install the vertical collar to oil pan bolts.

Torque bolts initially to 1.1 N·m (10 in. lbs.).

(b) Install the horizontal collar to transmission

bolts and torque to 55 N·m (40 ft. lbs.).

(c) Starting with the center vertical bolts and

working outward, final torque bolts to 55 N·m (40

ft. lbs.).

(8) Install oil filter and drain plug.

(9) Connect suspension stabilizer bar. Refer to

SUSPENSION for procedure.

(10) Lower vehicle and install oil dipstick and

tube.

(11) Fill engine crankcase with proper oil to cor-

rect level.

CRANKSHAFT

REMOVAL

(1) Remove engine from vehicle. Refer to procedure

in this section.

(2) Mount engine on an engine stand.

(3) Drain engine oil and remove oil filter.

(4) Remove oil pan and oil pick-up tube.

(5) Remove idler pulley bracket for accessory drive

belt.

(6) Remove upper intake manifold. Refer to proce-

dure in this section.

(7) Remove cylinder head covers.

(8) Remove timing chain cover.

(9) Remove primary timing chain.

(10) Remove crankshaft sprocket.

(11) Remove oil pump.

(12) Remove crankshaft rear oil seal retainer.

(13) Remove structural windage tray (Fig. 91).

(14) Turn crankshaft until connecting rod cap to be

removed is accessible.

NOTE: Connecting rod bearing caps are not inter-

changeable and should be marked before removing

to ensure correct reassembly.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(15) Mark connecting rod bearing cap positions

using a permanent ink marker or scribe tool.

(16) Remove connecting rod bearing caps. Use care

to prevent damage to the crankshaft bearing sur-

faces.

CAUTION: Care should be taken not to damage the

fractured rod and cap joint face surfaces or damage

to the engine may occur.

(17) Remove main bearing cap bolts and tie bolts

(Fig. 87).

(18) Remove main bearing caps (Fig. 87).

CAUTION: When removing crankshaft, use care not

to damage bearing surfaces on the crankshaft.

(19) Remove crankshaft from cylinder block.

INSTALLATION

NOTE: Upper and lower bearing halves are NOT

interchangeable.

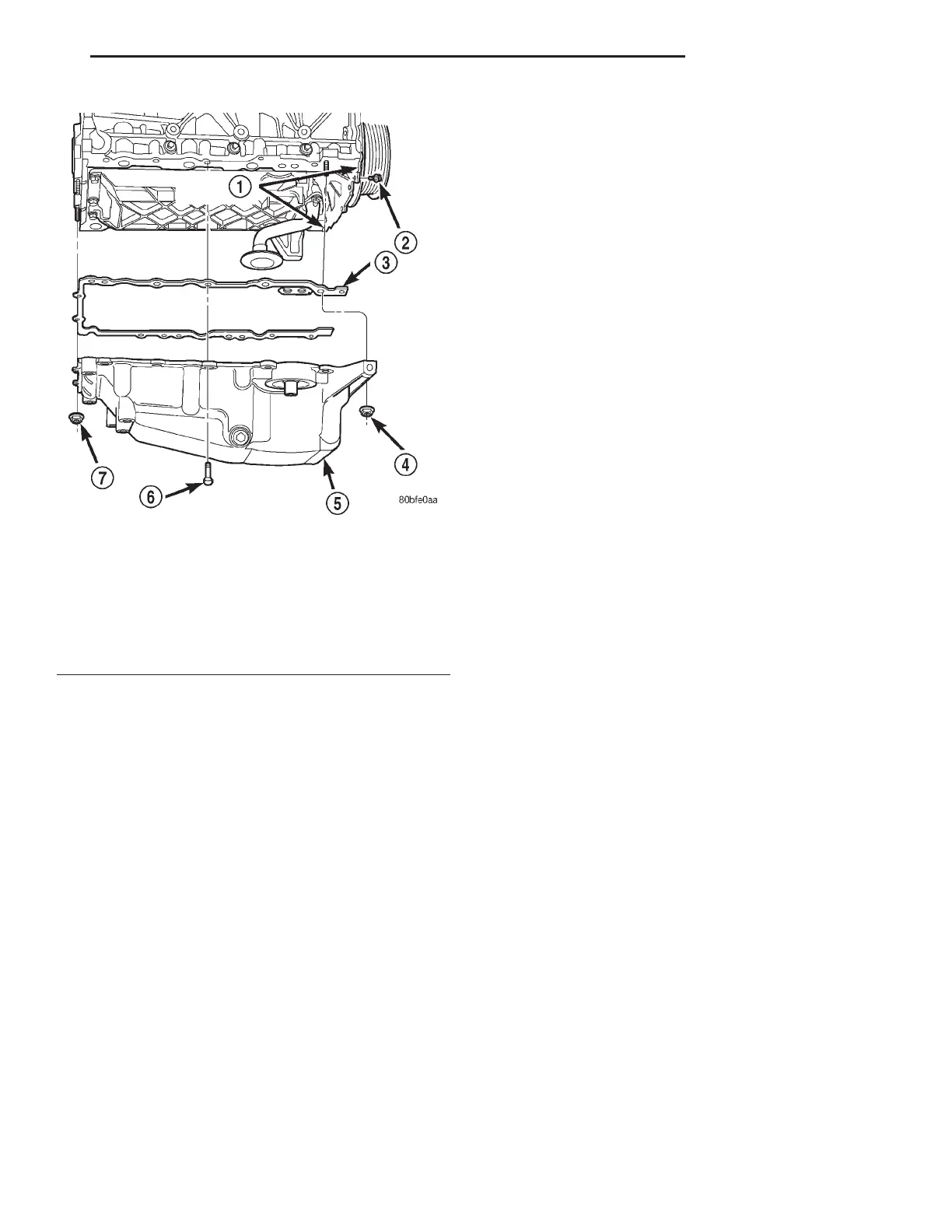

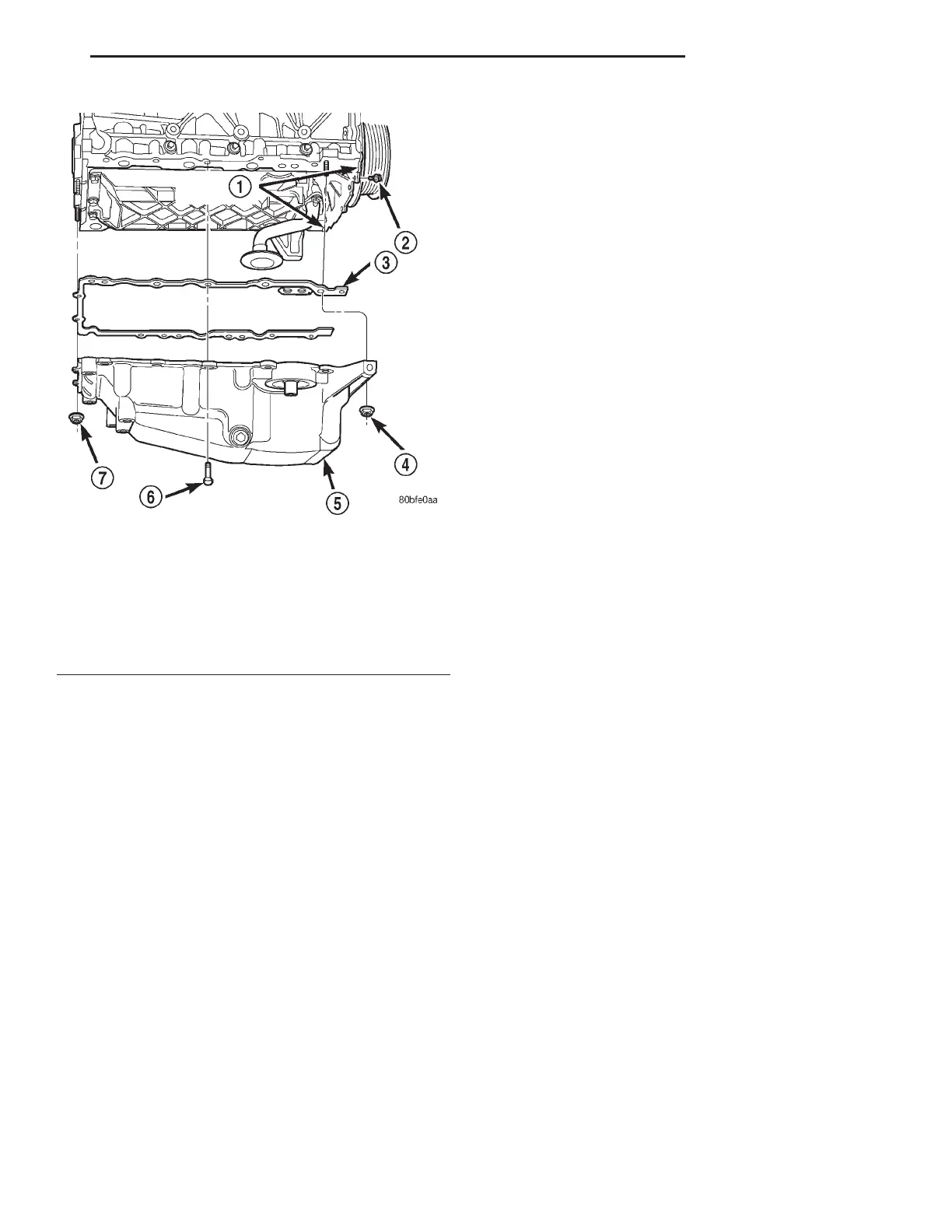

Fig. 86 Oil Pan

1 – SEALER LOCATION

2 – BOLT-M6

3 – GASKET

4 – NUT-M6

5 – OIL PAN

6 – BOLT-M8

7 – NUT-M6

LH 2.7L ENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...