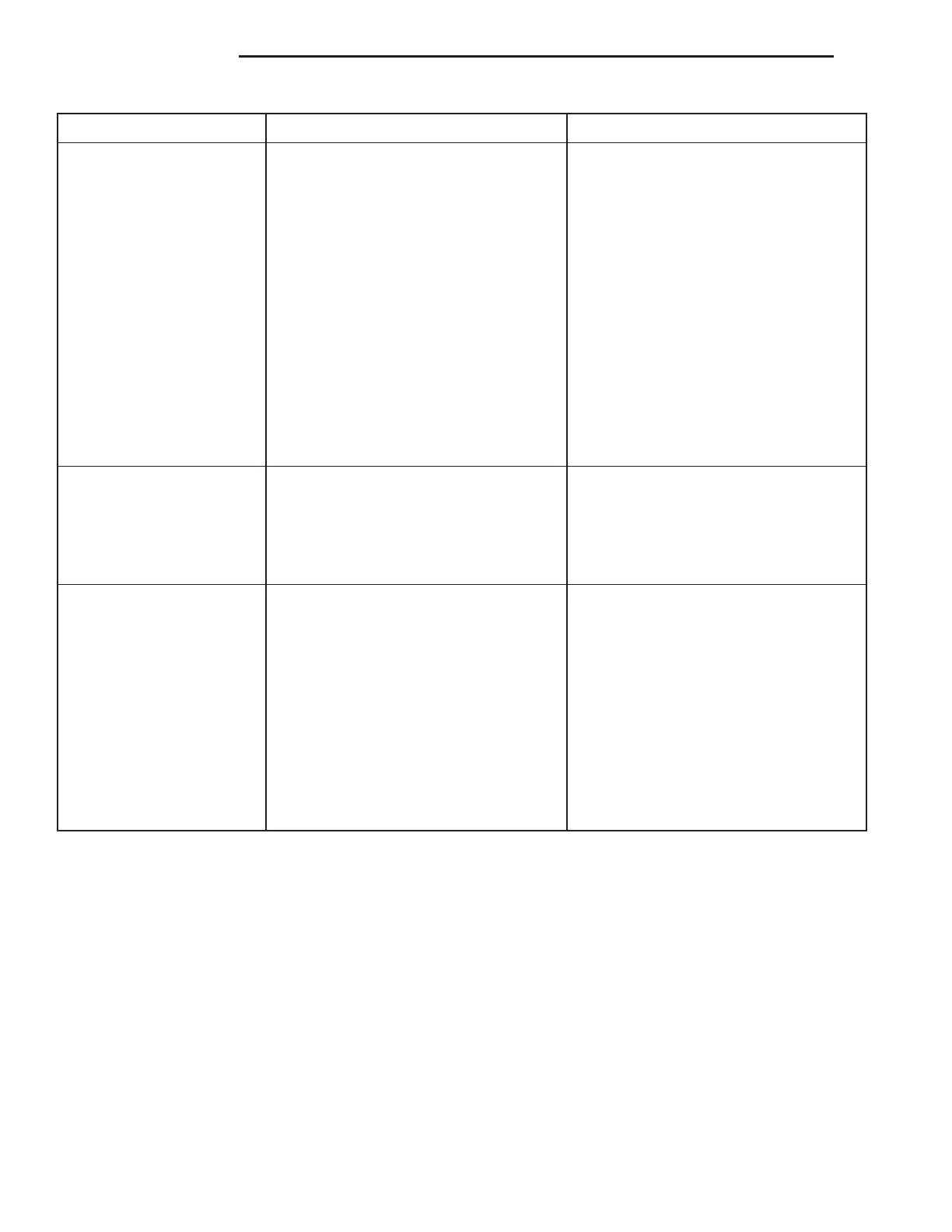

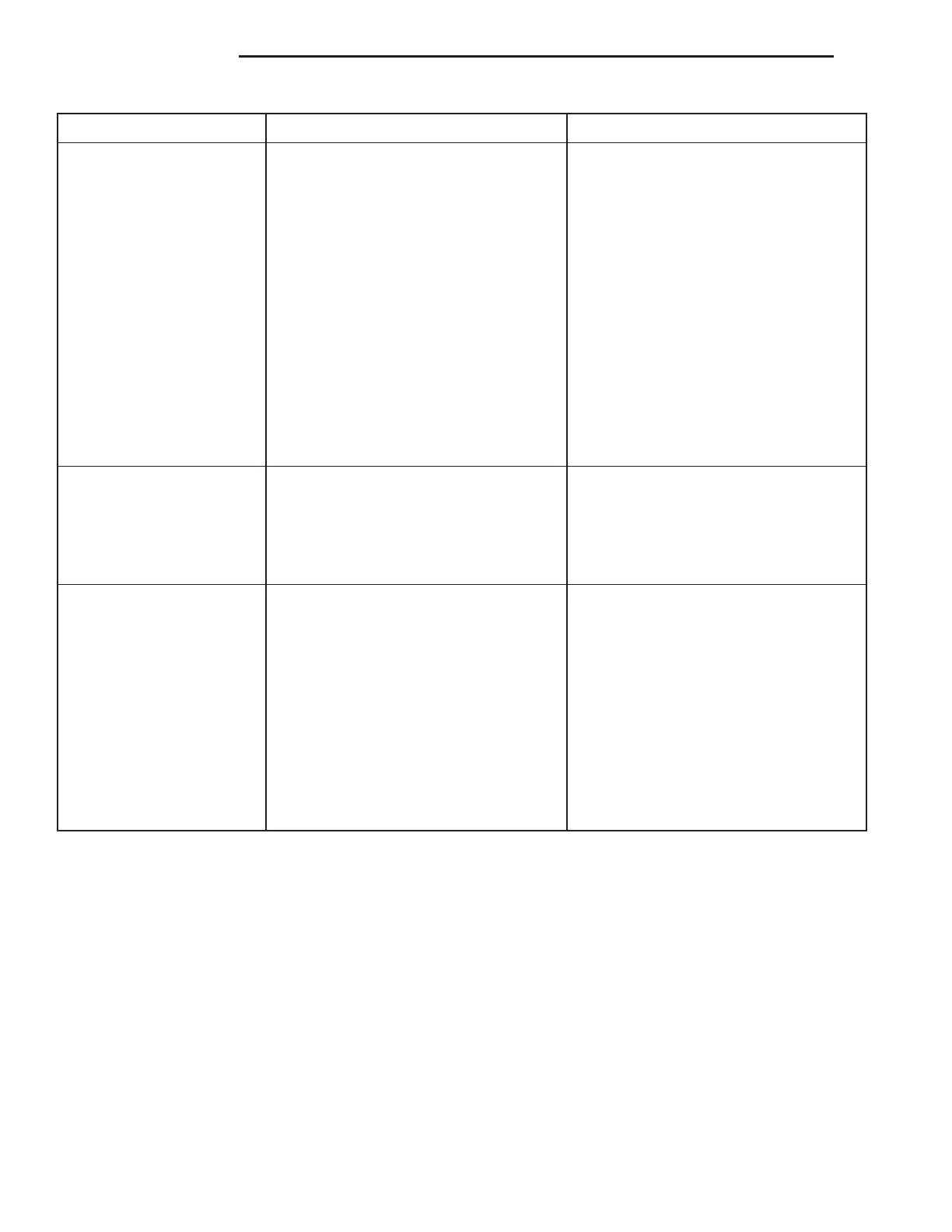

CONDITION POSSIBLE CAUSES CORRECTION

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main bearing

oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean, or

replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new tube

or clean, if necessary.

9. Oil pump cover warped or cracked. 9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated gaskets. 1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.

2. Tighten, repair or replace the part.

3. Misaligned or deteriorated cup or

threaded plug.

3. Replace as necessary.

OIL CONSUMPTION OR

SPARK PLUGS FOULED

1. PCV system malfunction. 1. Check system and repair as

necessary. Refer to EMISSION

CONTROL SYSTEMS.

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check grooves. If

groove is not proper width, replace

piston.

5. Worn valve guide(s). 5. Ream guide(s) and replace valve(s)

with oversize valve(s) and seal(s).

6. Valve stem seal(s) worn or damaged. 6. Replace seal(s).

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit and install

an oil pressure test gauge assembly.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not Run

engine at 3000 RPM

(3) Oil Pressure: Curb Idle 25 kPa (4 psi) mini-

mum 3000 RPM 170/724 kPa (25/105 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open or a

clogged oil pickup screen.

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM’S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

9 - 16 2.7L ENGINE LH

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...