SERVICE PROCEDURES

TIRE AND WHEEL BALANCE

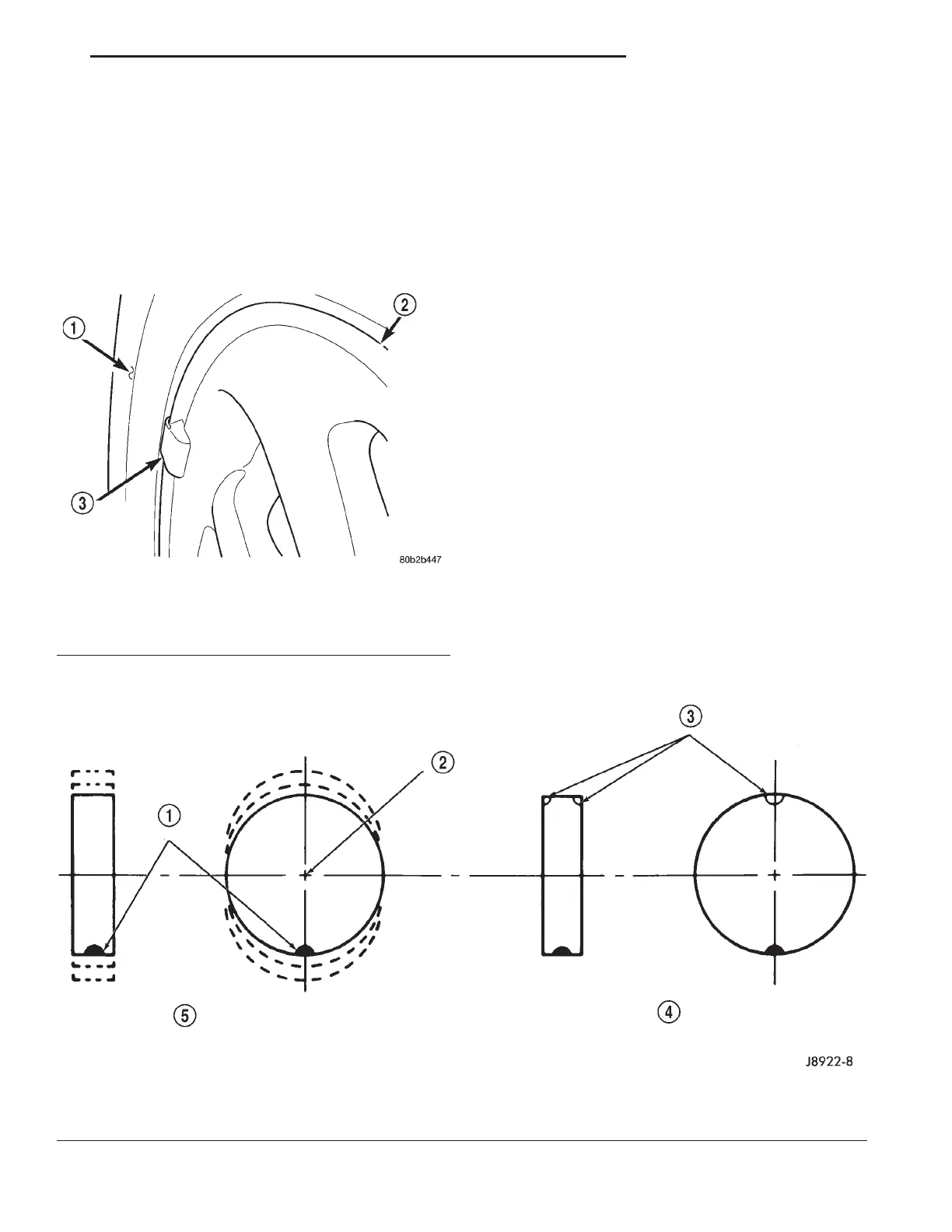

This vehicle uses a styled wheel weight (Fig. 9).

This wheel weight is designed to fit the contoured

surface of the wheel (Fig. 9). When balancing, this

wheel weight must be used. Do not use any other

type of wheel weight. It will not properly fit the con-

tour of the wheel.

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel. The vibration will be

noticed mostly when driving over 95 km/h (60 mph)

on a smooth road.

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly

require balancing. Static should be used only when a

two plane balancer is not available.

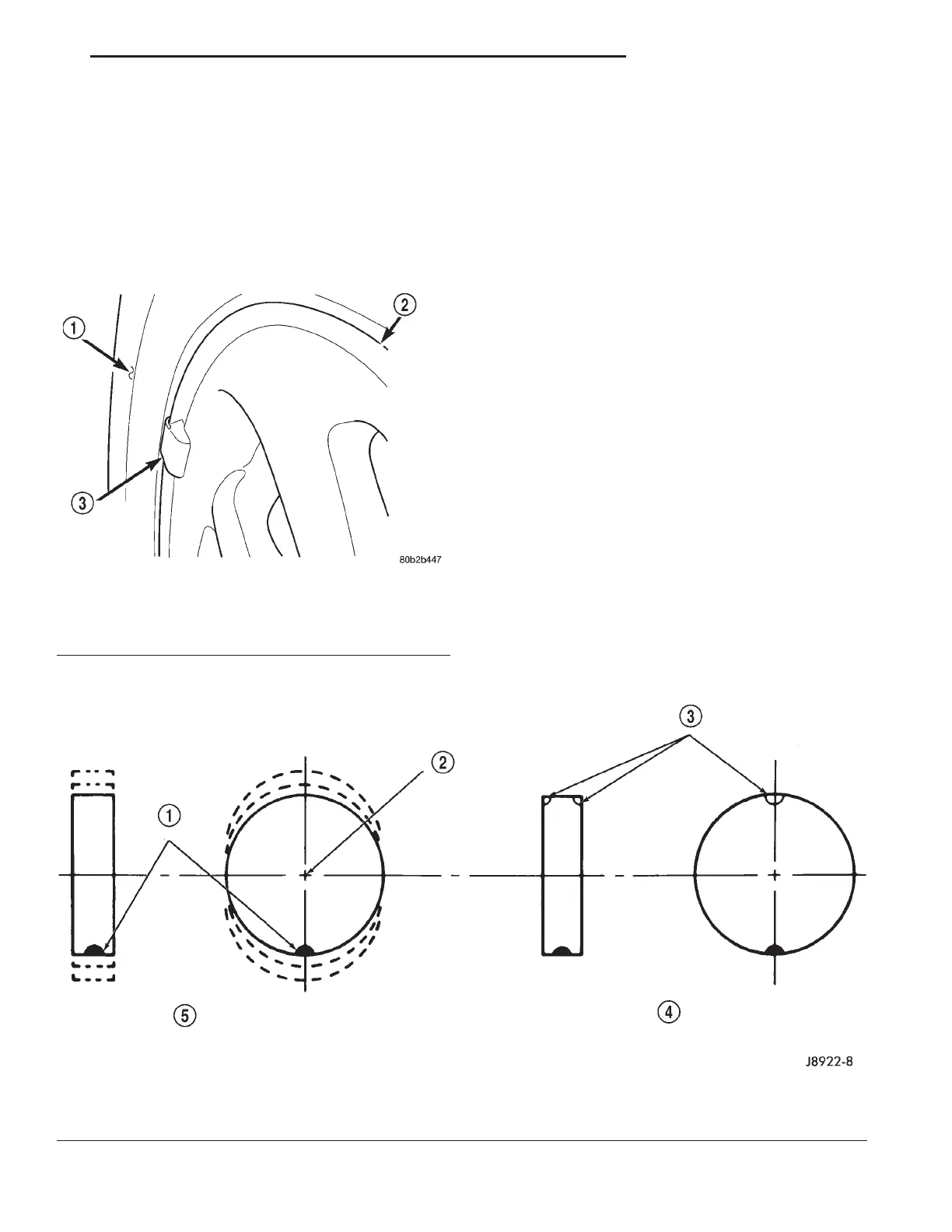

For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half of

this weight on the inner rim flange and the other

half on the outer rim flange (Fig. 10) (Fig. 11). Off-

vehicle balancing is necessary.

Wheel balancing can be accomplished with either

on or off vehicle equipment. When using on-vehicle

balancing equipment, remove the opposite wheel/tire.

Fig. 10 Static Unbalance & Balance

1 – HEAVY SPOT

2 – CENTER LINE OF SPINDLE

3 – ADD BALANCE WEIGHTS HERE

4 – CORRECTIVE WEIGHT LOCATION

5 – TIRE OR WHEEL TRAMP, OR WHEEL HOP

Fig. 9 Styled Wheel Weight

1 – TIRE

2 – WHEEL

3 – STYLED WHEEL WEIGHT

LH TIRES AND WHEELS 22 - 11

Loading...

Loading...