OPERATION

The injector contains a pintle that closes off an ori-

fice at the nozzle end. When electric current is sup-

plied to the injector, the armature and needle move a

short distance against a spring, allowing fuel to flow

out the orifice. Because the fuel is under high pres-

sure, a fine spray is developed in the shape of 2

streams. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The PCM provides battery voltage to each injector

through the ASD relay. Injector operation is con-

trolled by a ground path provided for each injector by

the PCM. Injector on-time (pulse-width) is variable,

and is determined by the PCM processing all the

data previously discussed to obtain the optimum

injector pulse width for each operating condition. The

pulse width is controlled by the duration of the

ground path provided.

Fuel injectors are fired one crankshaft revolution

before TDC compression. When cylinder #4 is at TDC

compression the injector for cylinder #1 will be ener-

gized.

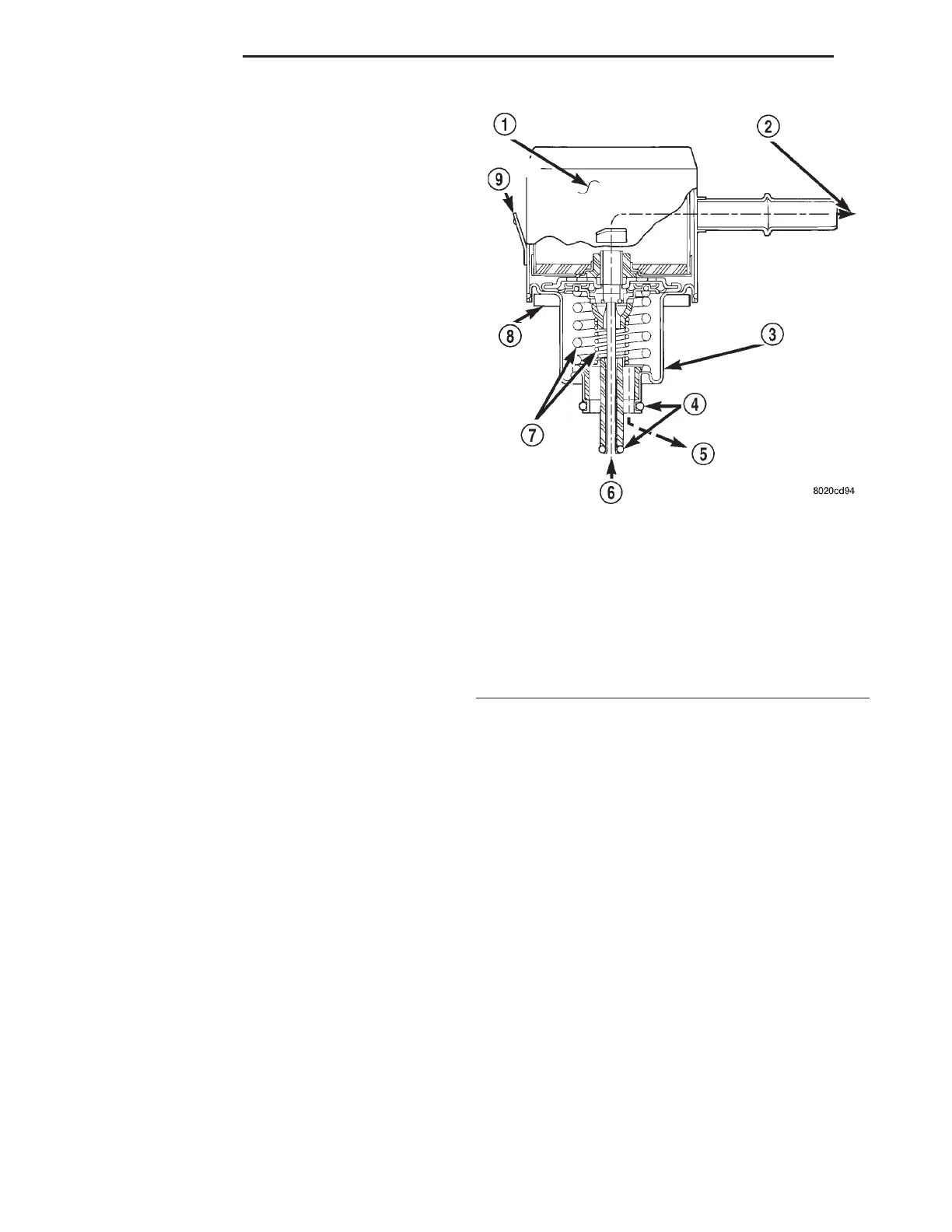

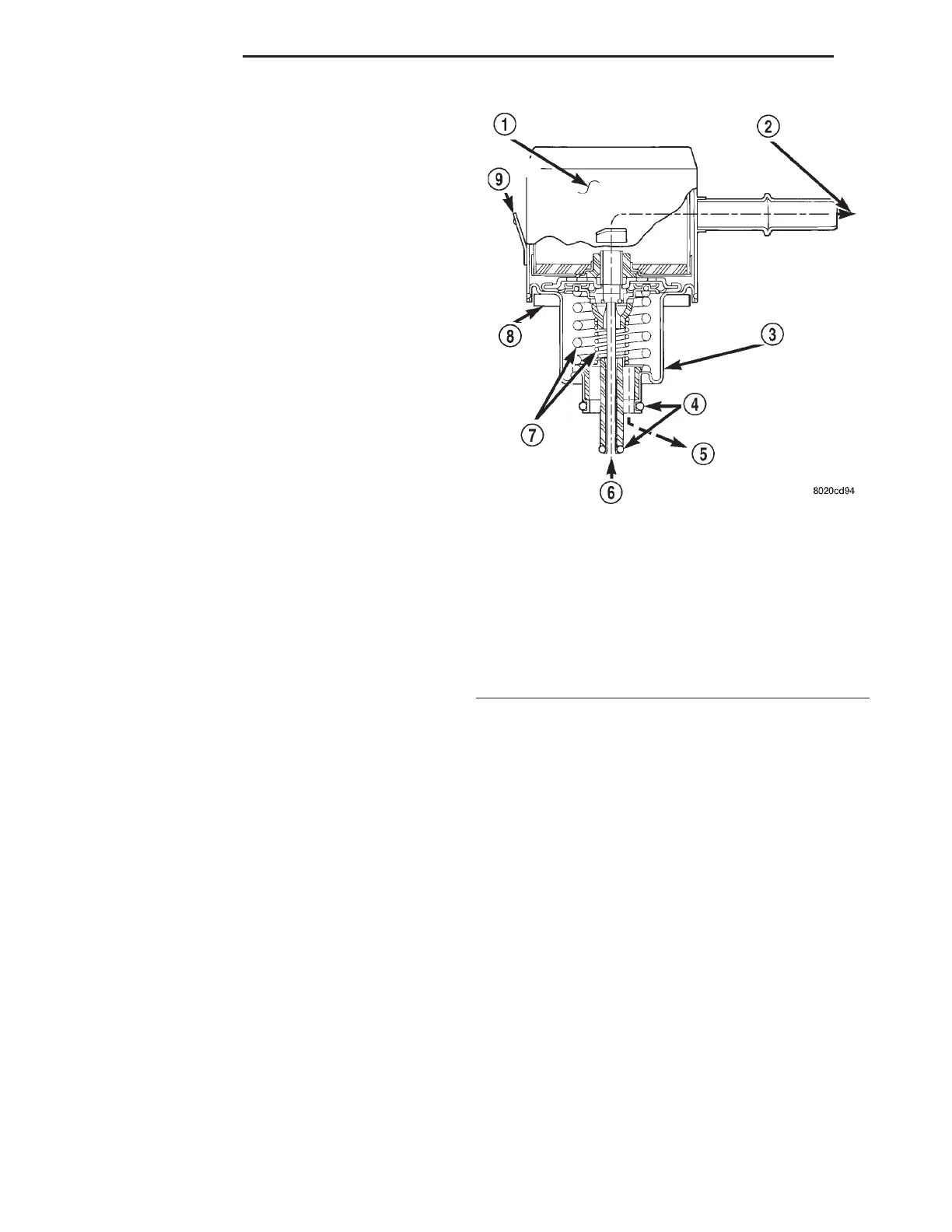

FUEL FILTER/FUEL PRESSURE REGULATOR

DESCRIPTION

A combination fuel filter and fuel pressure regula-

tor is used on all gas powered engines. It is located

on the top of the fuel pump module.

It contains a diaphragm, calibrated springs and a

fuel return valve. The internal fuel filter (Fig. 4) is

also part of the assembly.

OPERATION

Fuel Pressure Regulator Operation: The pres-

sure regulator is a mechanical device that is cali-

brated to maintain fuel system operating pressure of

approximately 400 kPa (58 psi) at the fuel injectors.

Fuel is supplied to the filter/regulator by the elec-

tric fuel pump through an opening tube at the bot-

tom of filter/regulator.

The fuel pump module contains a check valve to

maintain some fuel pressure when the engine is not

operating. This will help to start the engine.

If fuel pressure at the pressure regulator exceeds

approximately 58 psi, an internal diaphragm closes

and excess fuel pressure is routed back into the tank

through the pressure regulator. A separate fuel

return line is not used with any gas powered engine.

PRESSURE-VACUUM FILLER CAP

DESCRIPTION

The plastic fuel fill cap is threaded/quarter turn

onto the end of the fuel filler tube. It’s purpose is to

retain vapors and fuel in the fuel tank.

OPERATION

The fuel filler cap incorporates a two-way relief

valve that is closed to atmosphere during normal

operating conditions. The relief valve is calibrated to

open when a pressure of 17 kPa (2.5 psi) or vacuum

of 2 kPa (0.6 in. Hg) occurs in the fuel tank. When

the pressure or vacuum is relieved, the valve returns

to the normally closed position.

CAUTION: Remove the fuel filler cap to release fuel

tank pressure before disconnecting any fuel system

component.

Fig. 4 Side View—Filter/Regulator

1 – INTERNAL FUEL FILTER

2 – FUEL FLOW TO FUEL INJECTORS

3 – FUEL FILTER/FUEL PRESSURE REGULATOR

4 – O-RINGS

5 – EXCESS FUEL BACK TO TANK

6 – FUEL INLET

7 – CALIBRATED SPRINGS

8 – RUBBER GROMMET AT PUMP MODULE

9 – LOCKING TAB

14 - 4 FUEL SYSTEM LH

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...