HEADLAMP SWITCH

The headlamp switch is located on the upper left

side of the instrument panel. Refer to Group 8E,

Instrument Panel and Systems, for proper service

procedures.

HIGH-BEAM HEADLAMP SWITCH

The high beam headlamp switch is part of the

multi-function switch located on the steering column.

Refer to Group 8J, Turn Signals and Warning Flash-

ers, for proper service procedures.

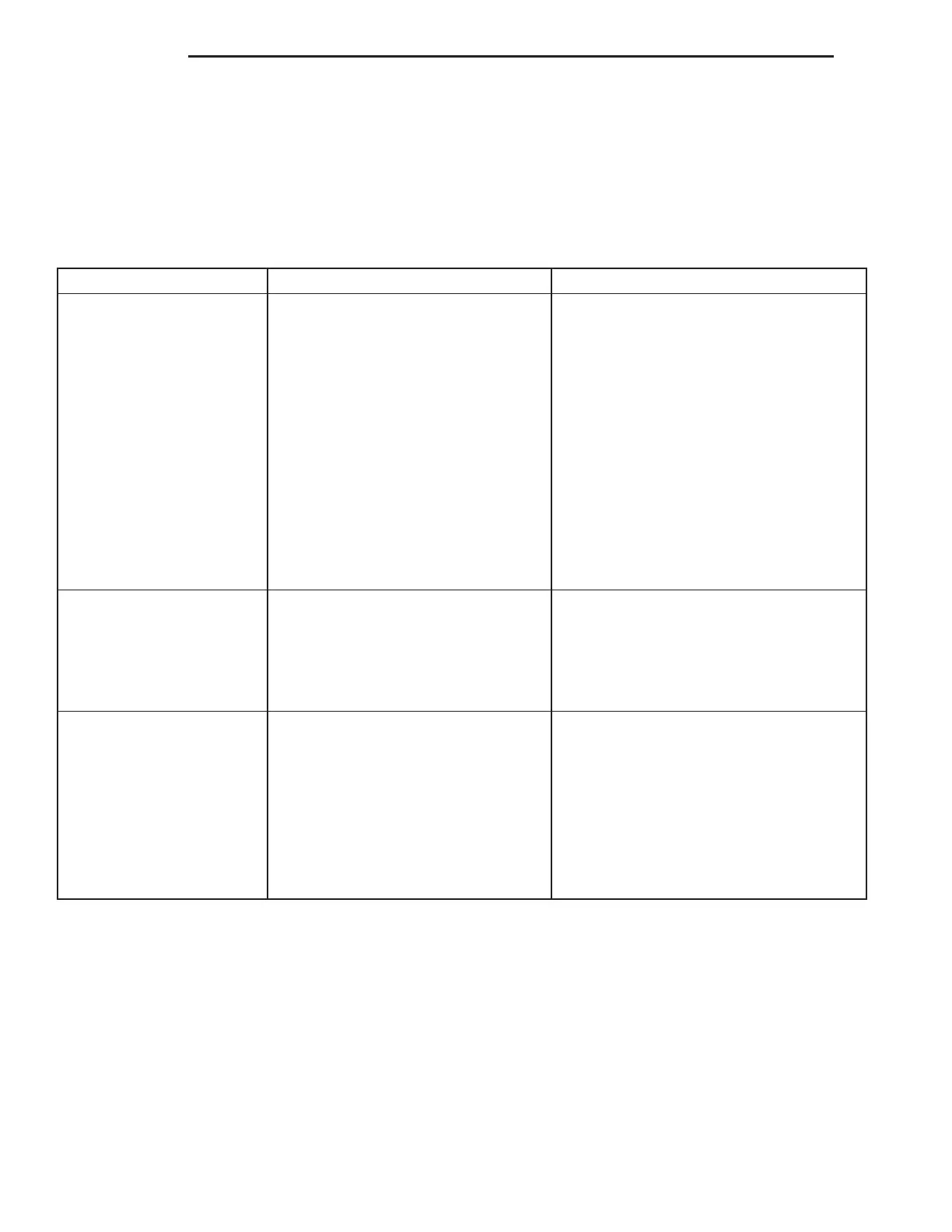

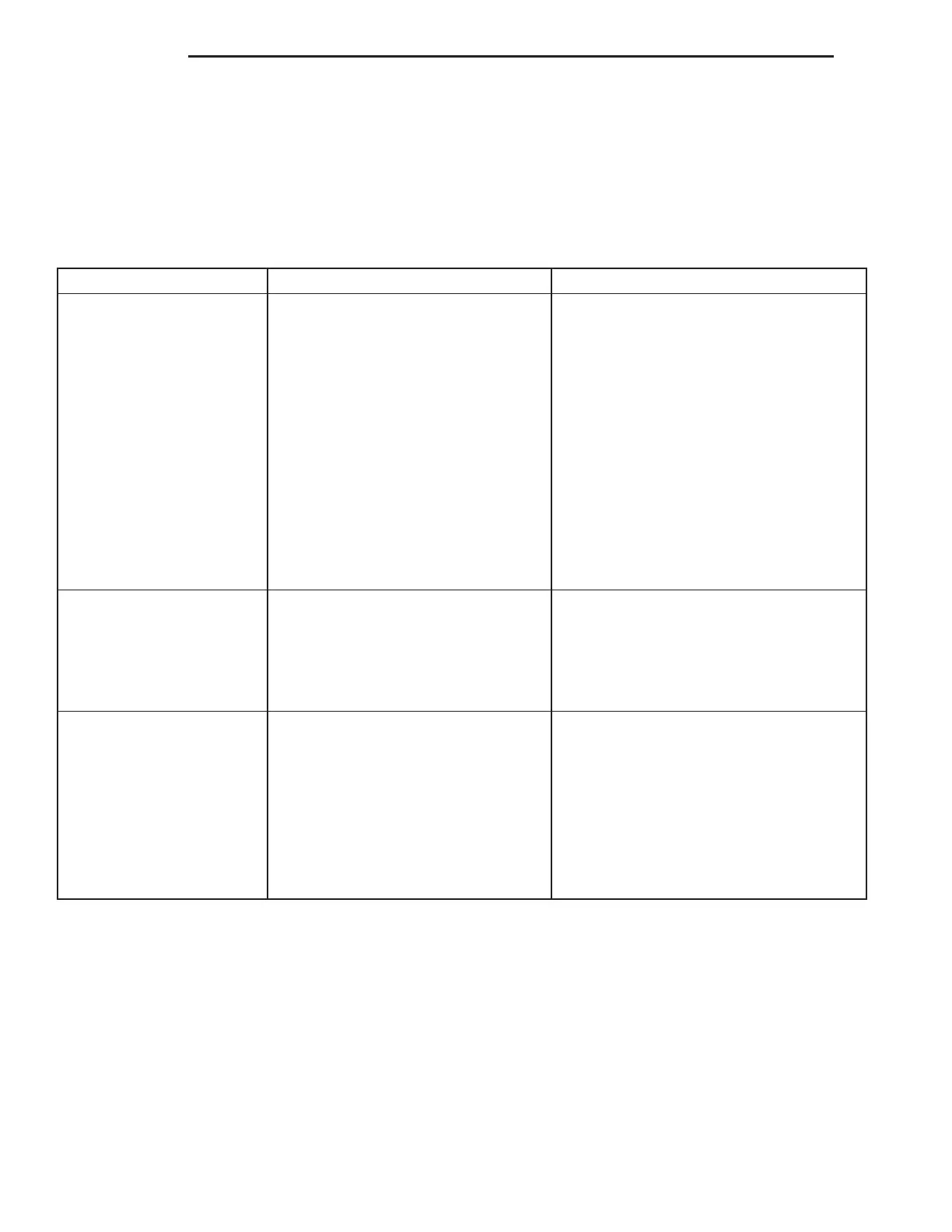

HEADLAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING OR

IGNITION TURNED OFF

1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer

to Group 8A, Battery

4. Battery has insufficient charge. 4. Test battery state-of-charge, refer to

Group 8A, Battery.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Group 8A,

Battery.

6. Poor lighting circuit Z1 ground. 6. Test for voltage drop across Z1 ground

locations, refer to Group 8W, Wiring

Diagrams.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT FREQUENTLY

1. Charging system output too high. 1. Test and repair charging system, refer

to Group 8A, Battery.

2. Loose or corroded terminals or

splices in circuit.

2. Inspect and repair all connectors and

splices, refer to Group 8W, Wiring

Diagrams.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE

1. Charging system output too low. 1. Test and repair charging system, refer

to Group 8A, Battery.

2. Poor lighting circuit Z1 ground. 2. Test for voltage drop across Z1 ground

locations, refer to Group 8W, Wiring

Diagrams.

3. High resistance in headlamp

circuit.

3. Test amperage draw of headlamp

circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

8L - 4 LAMPS LH

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...