INTAKE MANIFOLD VACUUM PORT REPAIR—

2.7L

The composite intake manifold vacuum ports can

be repaired. Although, if the manifold plenum cham-

ber is damaged or cracked, the manifold must be

replaced.

To repair a broken or damaged vacuum nipple

(port) on the composite intake manifold, perform the

following procedure:

PARTS REQUIRED TOOLS REQUIRED

Brass Nipple – 3/8” O.D.

x 1/4” pipe thread (Speed

Control Port)

Pipe Tap – 1/4” - 18 NPT

Brass Nibble – 1/2” O.D.

x 1/4” pipe thread (Brake

Booster Port)

Drill Bit – 7/16”

File/Sand Paper

NOTE: While performing this procedure, avoid get-

ting the manifold material residue into the plenum

chamber.

(1) File or sand the remaining port back until a

flat surface is obtained (plane normal to nipple (port)

axis).

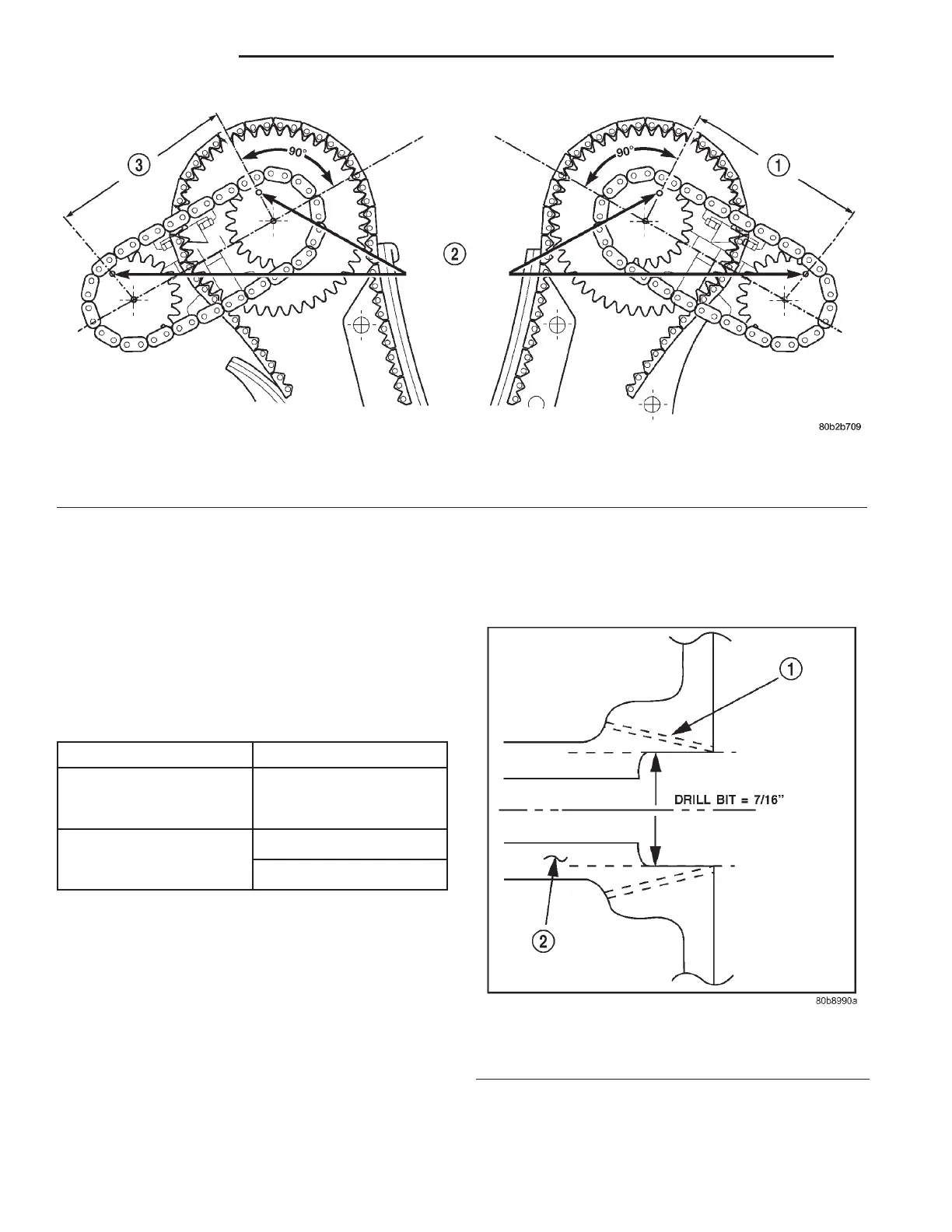

(2) Drill out the nipple (port) base using a 7/16”

drill bit (Fig. 38).

(3) Using a 1/4”–18 NPT pipe tap, cut internal

threads (Fig. 38). Use caution to start tap in a axis

same as original nipple.

(4) Apply Mopart Thread Sealant to threads of

repair nipple(s).

(5) Install repair nipple(s). Do not over torque

repair nipple(s).

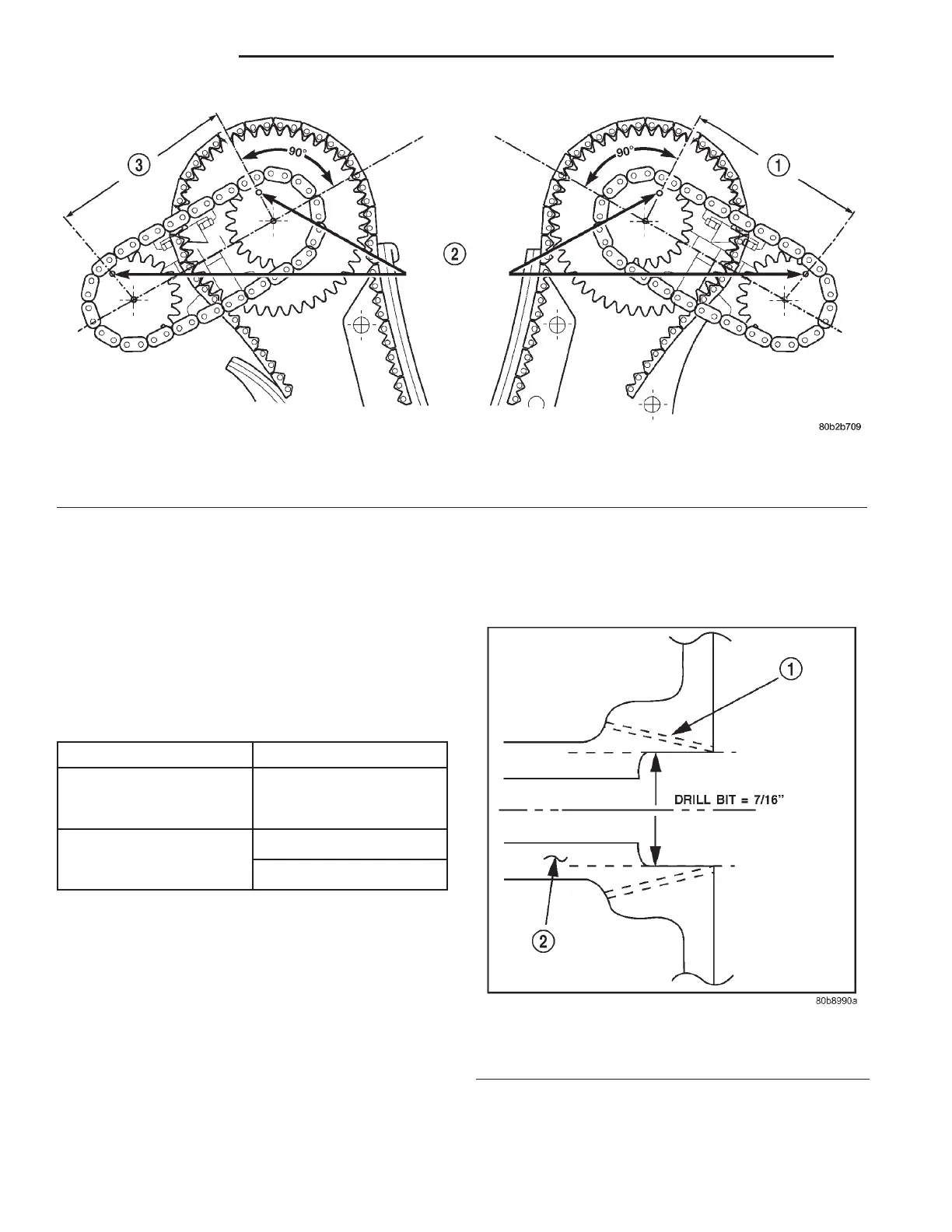

Fig. 37 Engine Timing

1 – 12 PINS

2 – CAMSHAFT TIMING MARKS

3 – 12 PINS

Fig. 38 Manifold Port (Nipple) Repair

1 – 1/4” — 18NPT PIPE TAP

2 – NIPPLE (PORT)

9 - 30 2.7L ENGINE LH

SERVICE PROCEDURES (Continued)

Loading...

Loading...