the garter spring is intact around the top of the rub-

ber seal. Install valve springs, valve retainers.

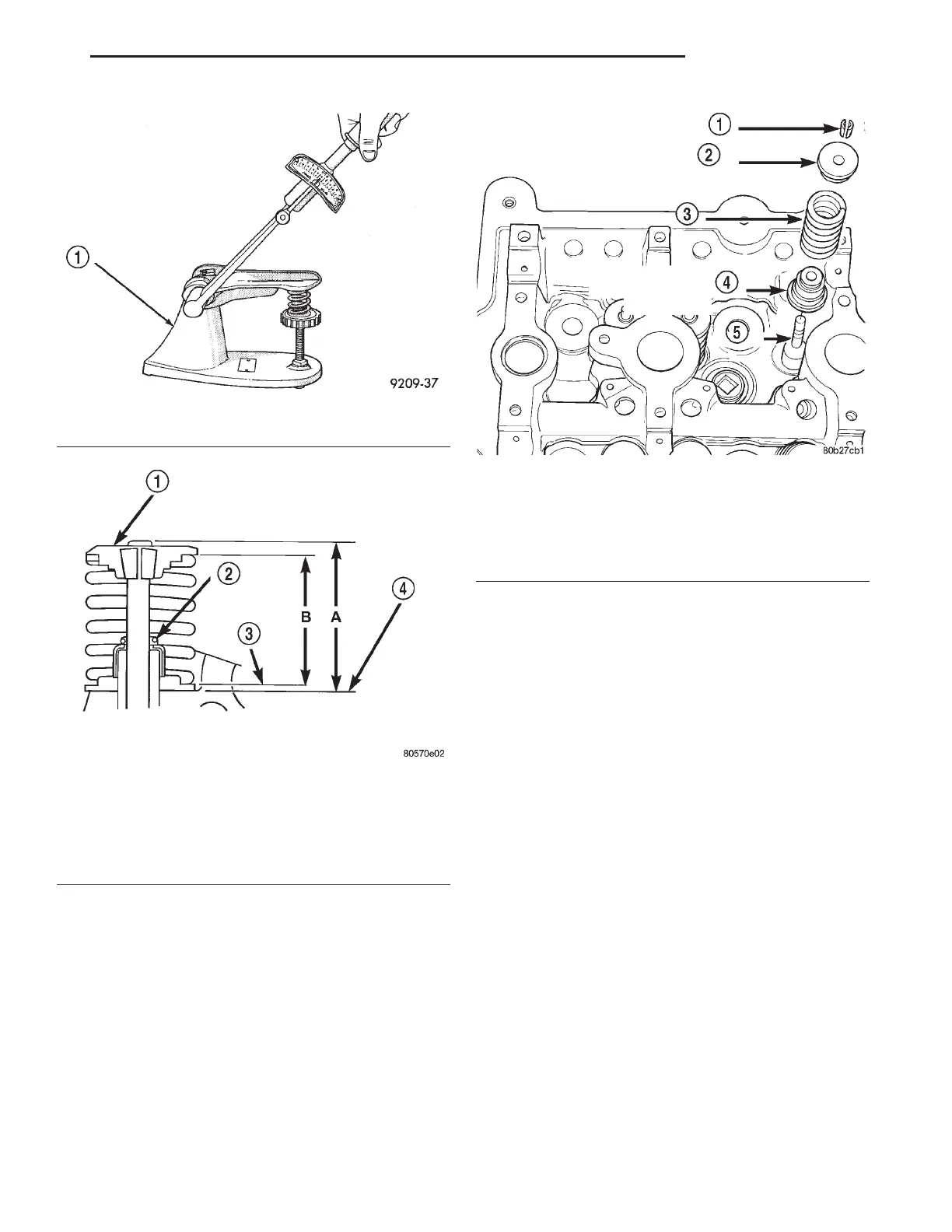

(4) Compress valve springs with a valve spring

compressor install locks and release tool. If valves

and/or seats are reground, measure the

installed height of springs (B) (Fig. 35), make

sure measurements are taken from top of

spring seat to the bottom surface of spring

retainer. If height is greater than 38.75 mm (1.5256

in.), install a 0.762 mm (0.030 in.) spacer in head

counterbore under the valve spring seat to bring

spring height back within specification.

ENGINE TIMING—VERIFICATION

Correct timing is critical for the NON free-wheel-

ing designed, 2.7L engine. Engine timing can be ver-

ified by using the following procedures:

(1) Remove cylinder head covers. Refer to proce-

dure in this section.

(2) Rotate engine until number one cylinder is at

TDC on the EXHAUST stroke.

(3) View the intake camshaft sprocket timing

mark. The mark should be 90° from the cylinder

head cover sealing surface (Fig. 37) on both right and

left cylinder banks.

(4) Count chain pins from the mark on the intake

camshaft towards the exhaust camshaft. Engine is

timed correctly when there are 12 chain pins

between the timing marks on the intake camshaft

and exhaust camshaft (Fig. 37).

(5) If marks are not correctly aligned, proceed to

Camshafts, Timing Chain and Sprockets, Removal

and Installation procedures.

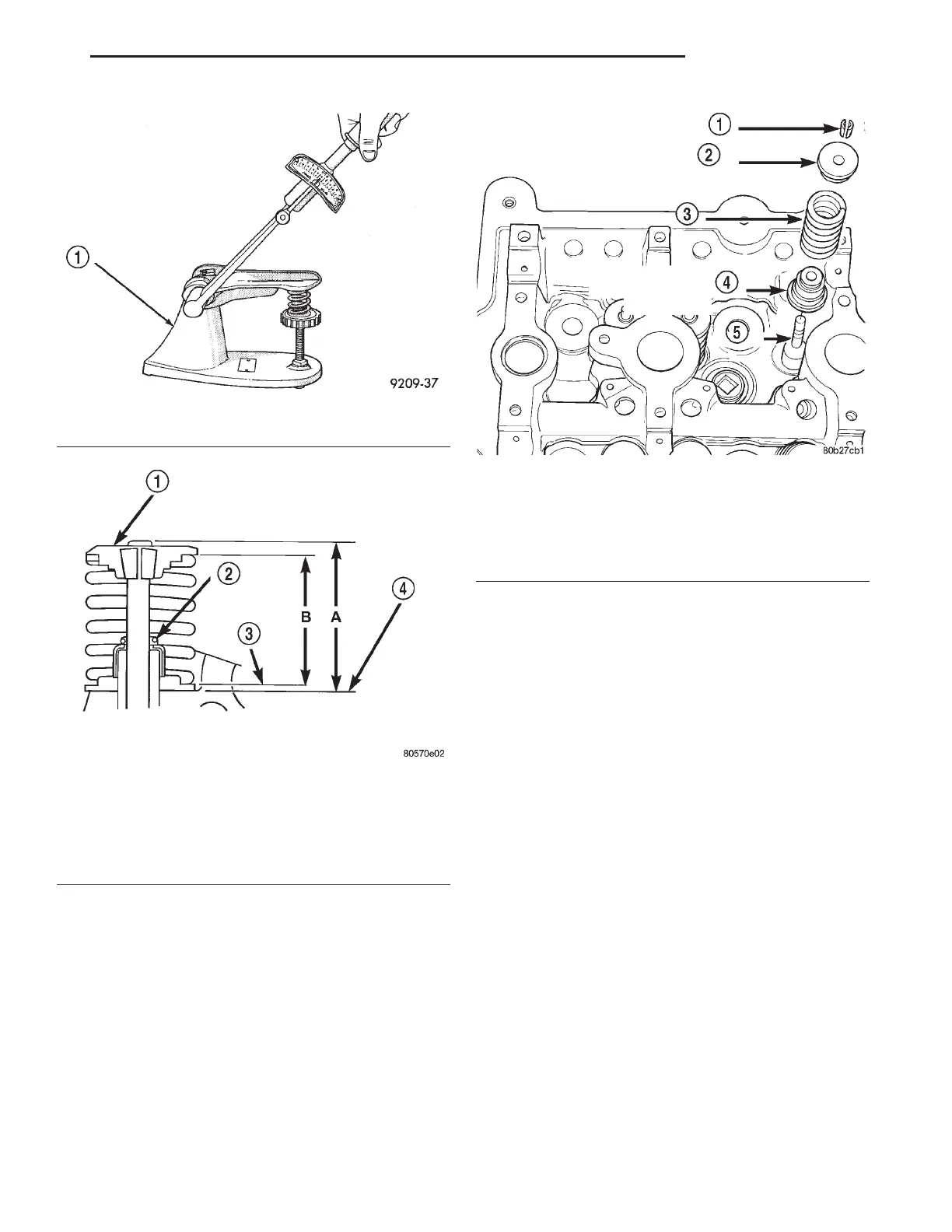

Fig. 34 Testing Valve Spring with Tool C-647

1 – SPECIAL TOOL C-647

Fig. 35 Checking Valve Tip Height and Valve Spring

Installed Height

1 – SPRING RETAINER

2 – GARTER SPRING

3 – VALVE SPRING SEAT TOP

4 – CYLINDER HEAD SURFACE

Fig. 36 Valve Seal and Spring

1 – VALVE RETAINING LOCKS

2 – VALVE SPRING RETAINER

3 – VALVE SPRING

4 – VALVE SEAL AND VALVE SPRING SEAT ASSEMBLY

5 – VALVE

LH 2.7L ENGINE 9 - 29

SERVICE PROCEDURES (Continued)

Loading...

Loading...